Flame-retardant plastic thread groove and a manufacturing process thereof

A technology of flame-retardant plastics and trunking, applied in the direction of fire-resistant coatings, electrical components, etc., can solve the problems of fire spread and easy ignition of trunking, and achieve the effect of increasing escape paths and improving smoke suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

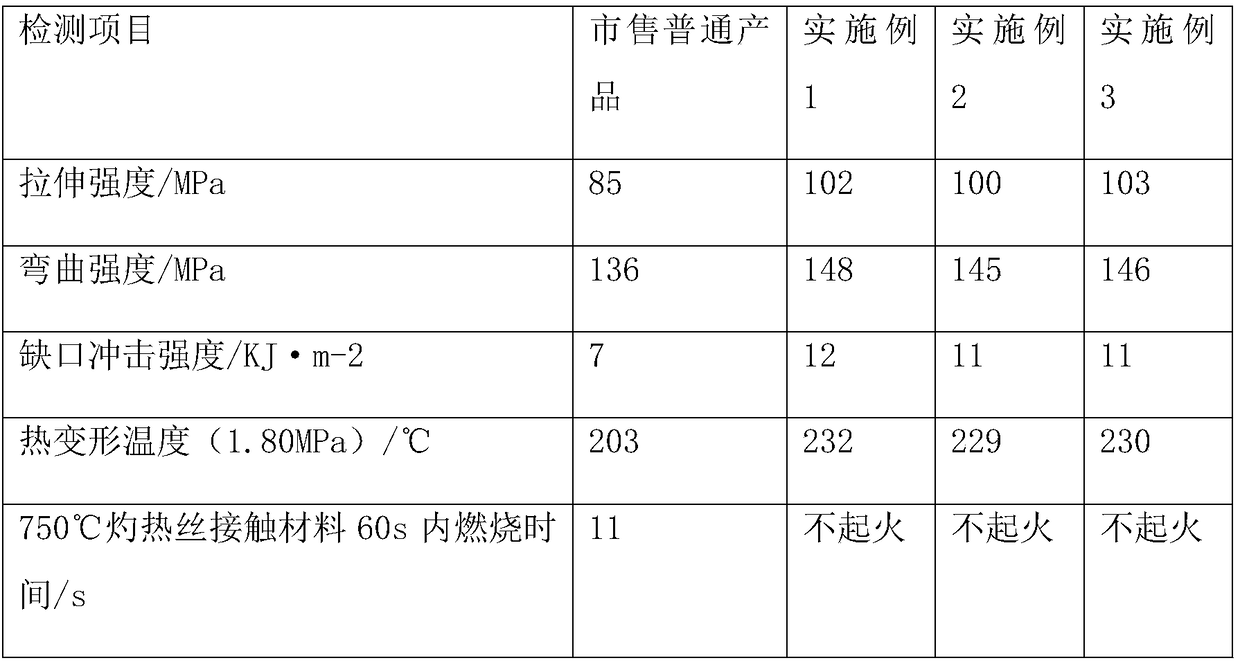

Examples

Embodiment 1

[0023] A flame-retardant plastic trunking provided in this embodiment includes a trunking body, and the surface of the trunking body is sequentially provided with an inner flame-retardant coating, a heat-absorbing layer and an outer flame-retardant coating.

[0024] The coating of the outer flame retardant coating comprises the following components by weight: 45 parts of polyvinyl acetate emulsion, 75 parts of ammonium polyphosphate, 35 parts of melamine, 8 parts of graphene oxide aqueous suspension of 2g / L, micro 0.35 parts of crystal paraffin, 0.35 parts of silicone defoamer, 0.35 parts of acrylic leveling agent, and 0.35 parts of propylene glycol methyl ether acetate.

[0025] The coating preparation method of the outer flame retardant coating is as follows:

[0026] S1. Add the graphene oxide aqueous suspension into the polyvinyl acetate emulsion, and mix evenly for 45 minutes to obtain a mixed emulsion;

[0027] S2. Stir the deionized water, ammonium polyphosphate, melam...

Embodiment 2

[0033] A flame-retardant plastic trunking provided in this embodiment includes a trunking body, and the surface of the trunking body is sequentially provided with an inner flame-retardant coating, a heat-absorbing layer and an outer flame-retardant coating.

[0034] The coating of the outer flame retardant coating comprises the following components by weight: 53 parts of polyvinyl acetate emulsion, 82 parts of ammonium polyphosphate, 39 parts of melamine, 9 parts of graphene oxide aqueous suspension of 2g / L, micro 0.40 parts of crystal paraffin, 0.40 parts of silicone defoamer, 0.40 parts of acrylic leveling agent, and 0.40 parts of propylene glycol methyl ether acetate.

[0035] The coating preparation method of the outer flame retardant coating is as follows:

[0036] S1. Add the graphene oxide aqueous suspension into the polyvinyl acetate emulsion, and mix evenly for 55 minutes to obtain a mixed emulsion;

[0037] S2. Stir the deionized water, ammonium polyphosphate, melam...

Embodiment 3

[0043] A flame-retardant plastic trunking provided in this embodiment includes a trunking body, and the surface of the trunking body is sequentially provided with an inner flame-retardant coating, a heat-absorbing layer and an outer flame-retardant coating.

[0044] The coating of the outer flame retardant coating comprises the following components by weight: 60 parts of polyvinyl acetate emulsion, 90 parts of ammonium polyphosphate, 40 parts of melamine, 10 parts of graphene oxide aqueous suspension of 2g / L, micro 0.45 parts of crystal paraffin, 0.45 parts of silicone defoamer, 0.45 parts of acrylic leveling agent, and 0.45 parts of propylene glycol methyl ether acetate.

[0045] The coating preparation method of the outer flame retardant coating is as follows:

[0046] S1, adding the graphene oxide aqueous suspension into the polyvinyl acetate emulsion, and uniformly mixing for 60 minutes to obtain a mixed emulsion;

[0047] S2. Stir the deionized water, ammonium polyphosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com