A single grout and a tunnel stabilization method using the same

A single-slurry, tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems that the expected reinforcement effect cannot be achieved, the cement slurry is difficult to pour, and the cement slurry is easy to lose, so as to reduce the time of entry and exit, and improve The effect of spreading and spreading and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

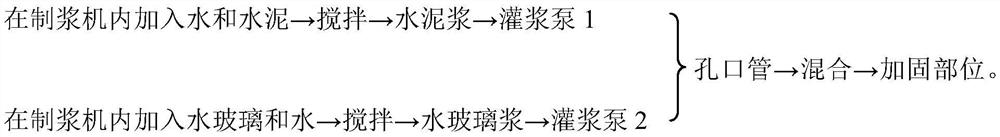

Method used

Image

Examples

specific Embodiment 1

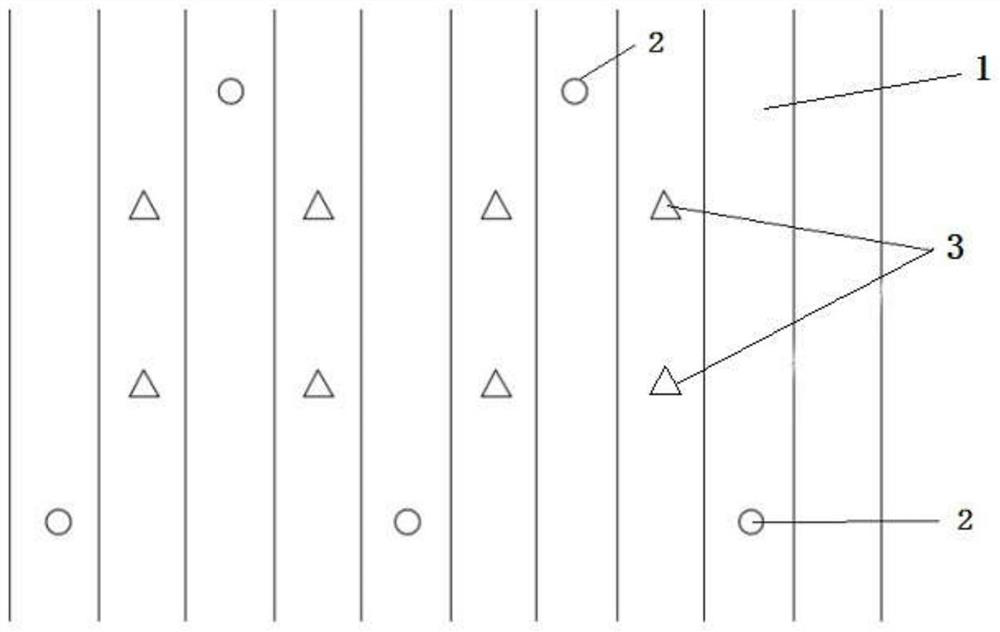

[0086] An operating shield subway tunnel is located in a water-rich powder-fine sand geological environment. The water content of the powder-fine sand layer is 23-31%, the saturation is 84-100%, and the sand diameter is 0.075-0.25mm, accounting for 38-73%. Good water permeability. The subway has been in operation for many years. Affected by the vibration of the subway, the fine sand layer at the base of the tunnel has been corroded and lost, resulting in uneven settlement of the subway structure. The maximum sinking position is about 15-17cm. It will directly affect the safe running of the track.

[0087] In this embodiment, the single grout of the following formula by weight is used for grouting reinforcement:

[0088] Water: cement = 80: 100;

[0089] Water glass: cement = 1.8: 100;

[0090] Early strength agent: cement = 5:100;

[0091] Among them, the early strength agent is selected from inorganic normal salts or acid salt compounds (such as: sodium acetate, sodium ph...

specific Embodiment 2

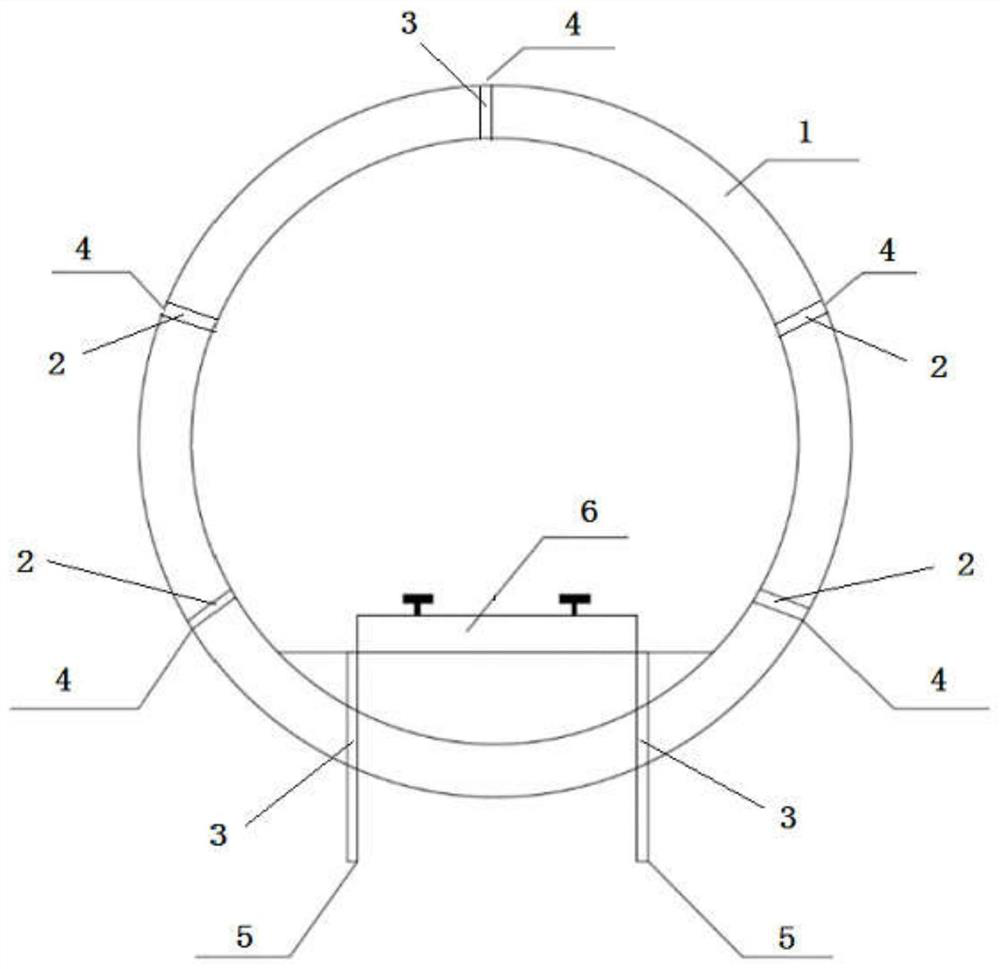

[0096] A shield tunnel that has been built and operated for one year was affected by the vibration of the vehicle, and the mud-sand layer at the base of the tunnel settled, with an uneven settlement of about 2.0cm. In order to control the settlement of the tunnel and ensure the safe operation of the subway, a single grout is used for grouting reinforcement. This treatment only grouts the rear wall grouting hole of the lower semicircular side wall of the tunnel. Specifically, the grouting hole behind the wall at the 4 o'clock position and the 8 o'clock position can be selected for grouting, and the grouting pressure is 0.4mpa. The formula in parts by weight of the single grout used in the grouting process is as follows:

[0097] Water: cement = (60 ~ 80): 100;

[0098] Water glass: cement = (0.8 ~ 1.6): 100;

[0099] Early strength agent: cement = 3:100;

[0100] Water reducer: cement = 1:100;

[0101] Among them, the early strength agent is selected from inorganic normal s...

specific Embodiment 3

[0104] The shield tunnel under construction for track laying, due to the sudden increase of water pressure behind it, the tunnel structure will rise, and the tunnel segments will be staggered, with a maximum staggered amount of 3-5cm. In order to ensure the safety of the tunnel structure and smooth track laying, the grouting hole behind the wall located on the upper semicircular side wall of the original structure is used for grouting reinforcement. The weight formula of the single grout used in the grouting process is as follows:

[0105] Water: cement = (60 ~ 80): 100;

[0106] Water glass: cement = (1.5~2.0): 100;

[0107] Early strength agent: cement = 3:100;

[0108] Tackifier: cement = 3:100;

[0109] Wherein, the early strength agent is selected from inorganic normal salt or acid salt compound (such as: sodium acetate, sodium phosphate, sodium aluminate nitrite and acid salt); the thickener is selected from inorganic bentonite or organic cellulose, such as Na-based b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com