Dispersing agent used for preparing samples for diamond micropowder morphology detection

A diamond micropowder and dispersant technology, applied in the field of diamond micropowder quality inspection, can solve the problems of strong fluidity, difficult observation, unfavorable picture preservation and file retention, etc., and achieve the effect of clear picture and clear sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Used to detect the morphology of diamond powder with a particle size of W25-35

[0019] 1) Mix polyethylene glycol 600 and glycerin at a volume ratio of 10:1 to prepare 500ml of new dispersant for use;

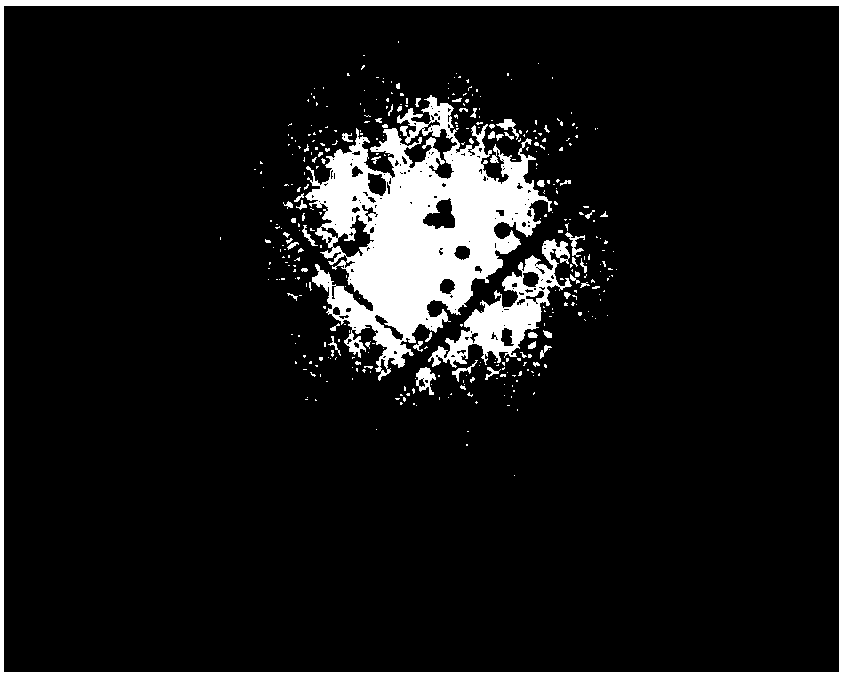

[0020] 2) According to the conventional sample preparation method, absorb the dispersant with a straw and drop it on the glass slide, then take a small amount of the micropowder to be tested with a bamboo stick, stir it with the dispersant evenly, then cover it with a cover glass, and then Use the other end of the bamboo stick to gently press on the cover glass to observe under the microscope. figure 1 For the pictures taken under a microscope (objective 4 x eyepiece 10).

Embodiment 2

[0022] Used to detect the morphology of diamond powder with a particle size of W0-1.5

[0023] 1) Mix polyethylene glycol 600 and glycerin at a volume ratio of 10:1 to prepare 500ml of new dispersant for use;

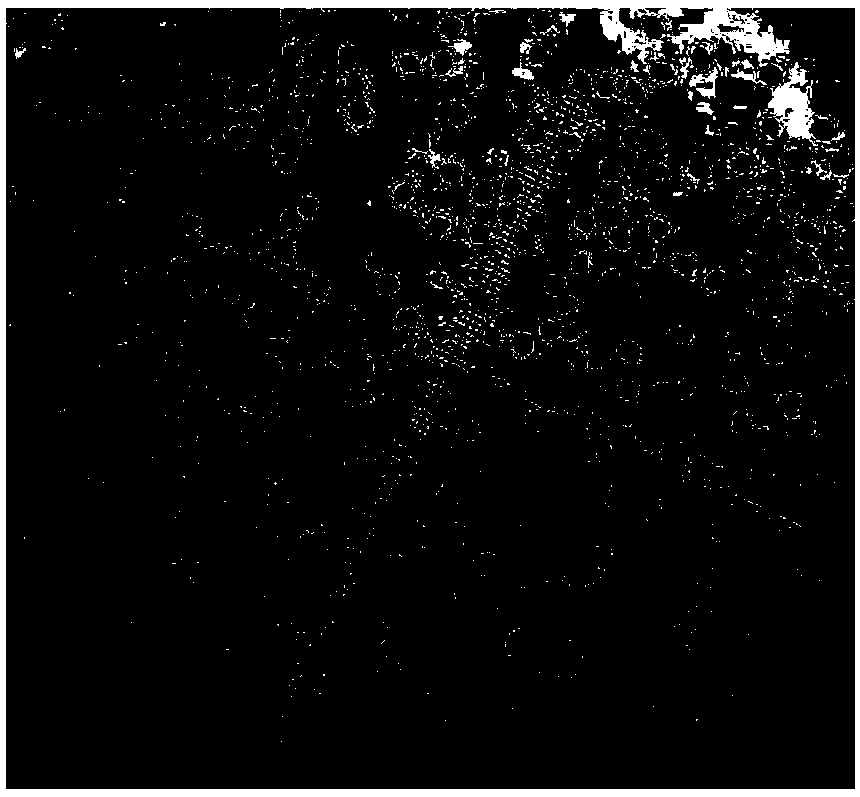

[0024] 2) According to the conventional sample preparation method, absorb the dispersant with a straw and drop it on the glass slide, then take a small amount of the micropowder to be tested with a bamboo stick, stir it with the dispersant evenly, then cover it with a cover glass, and then Use the other end of the bamboo stick to gently press on the cover glass to observe under the microscope. image 3 It is a picture taken under a microscope (objective lens 100×eyepiece lens 10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com