Short-pier shear wall with embedded prestressing force combination oblique supporting member

A prestressed and shear wall technology, applied in the direction of walls, building components, and earthquake resistance, can solve the problems of unfavorable abdominal steel-concrete coordination, the reduction of the thickness of the outer concrete protective layer, and the reduction of the plane stability of the wall, etc., to achieve Improve unfavorable stress state, improve stiffness degradation, stable and reliable safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation structure of the present invention will be described below in conjunction with the accompanying drawings.

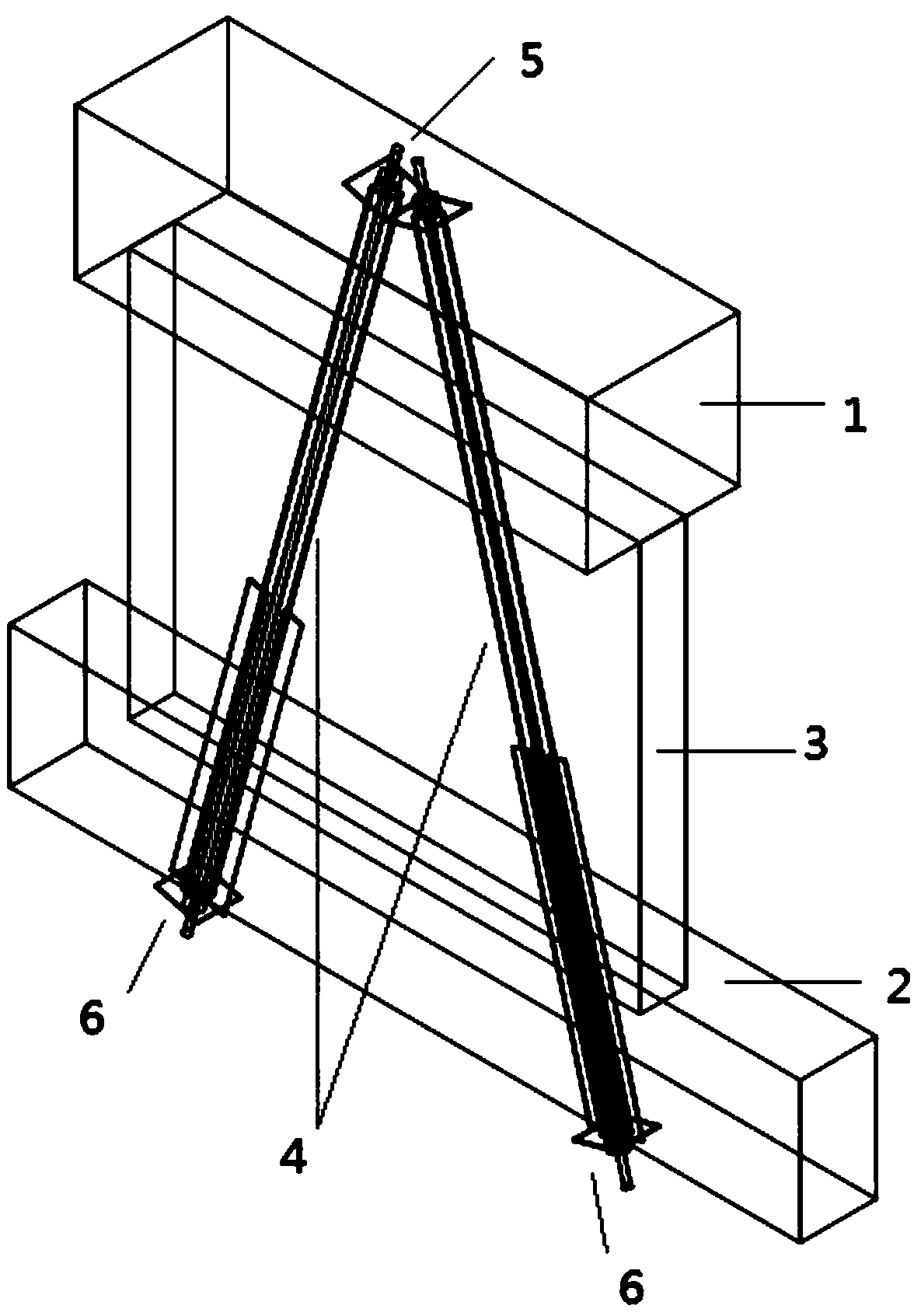

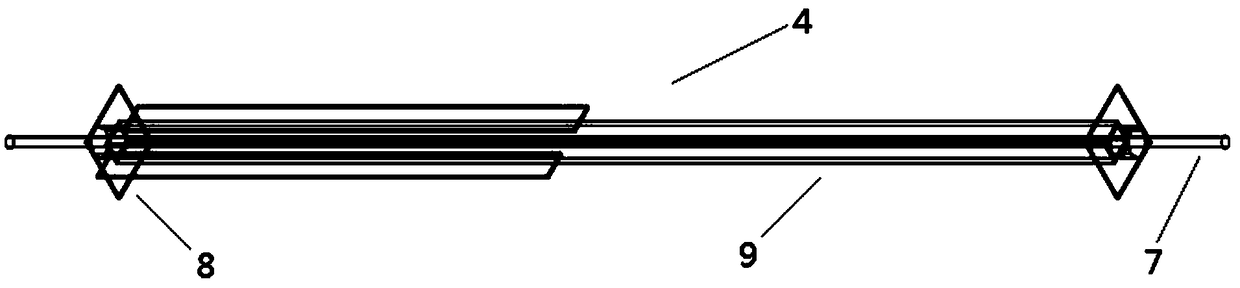

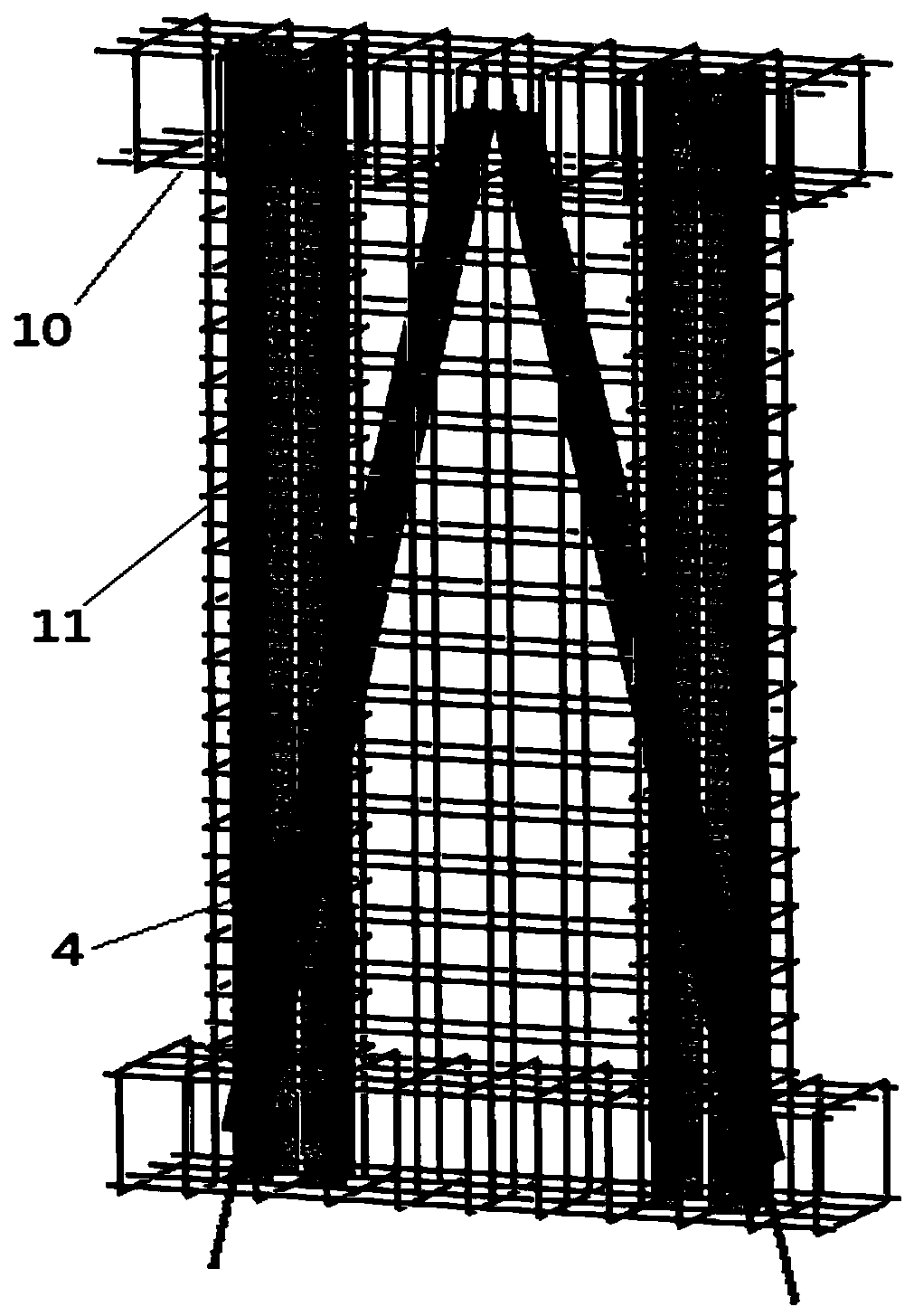

[0017] Such as figure 1 and figure 2 As shown, the short-limb shear wall with built-in prestressed composite braces of the present invention includes upper beam 1, lower beam 2, short limb wall limb 3, prestressed composite diagonal brace 4; short limb wall limb 3 is fixedly connected to the upper layer The beam 1 and the lower beam 2 are in an I-shape as a whole; there are two groups of prestressed composite braces 4, which are located inside the wall pier 3 of the short wall, and are in the shape of a herringbone. The anchorage end 5 of the prestressed composite brace 4 is connected to the upper beam 1 , the tension end 6 of the prestressed composite brace 4 is connected to the lower beam 2 through the anchor pad 8; the shape of the anchor pad 8 is preferably π-shaped, which plays a role in dispersing local stress.

[0018] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com