Bismuth oxide photocatalyst containing bismuth defects in different crystal phases and preparation method thereof

A technology of photocatalyst and bismuth oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. Electron migration efficiency, hindering the application of photocatalytic technology and other issues, to achieve the effect of improving the utilization rate of visible light, low economic cost of production, and broadening the response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

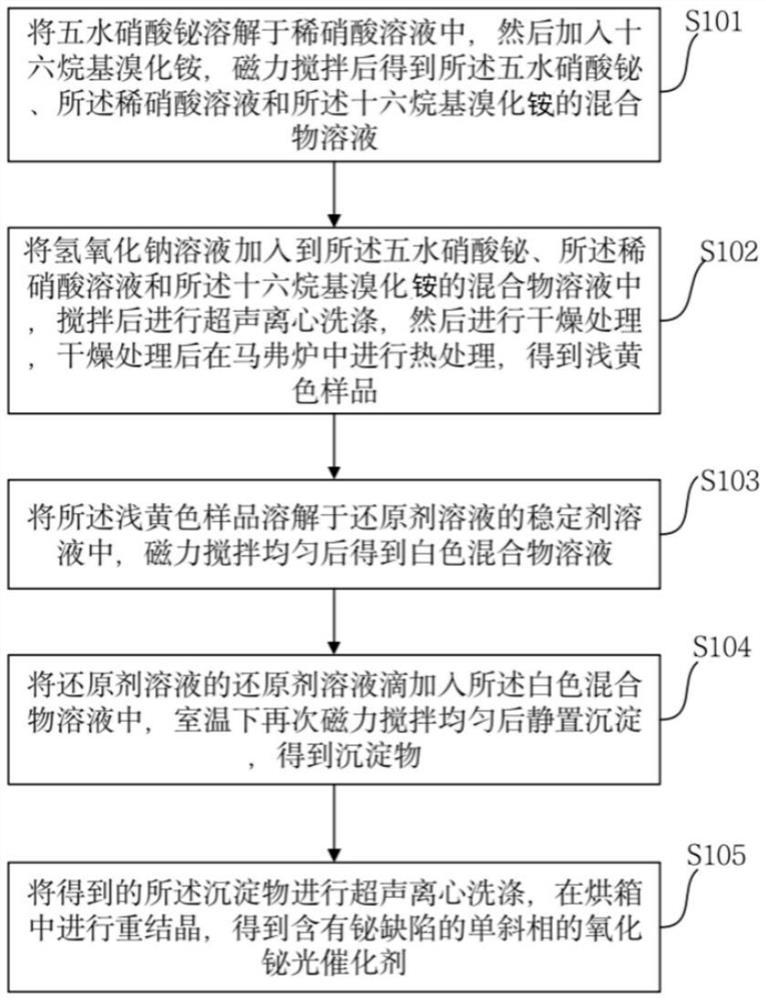

[0055] see figure 1 , is a flow chart of the method for preparing a monoclinic bismuth oxide photocatalyst containing bismuth defects provided in the examples of the present application. A method for preparing a bismuth oxide photocatalyst containing bismuth defects in a monoclinic phase, the preparation method comprising:

[0056] Step S101, dissolving bismuth nitrate pentahydrate in dilute nitric acid solution, then adding cetyl ammonium bromide, and obtaining the bismuth nitrate pentahydrate, the dilute nitric acid solution and the cetyl ammonium bromide after magnetic stirring Ammonium mixture solution;

[0057] Step S102, adding the sodium hydroxide solution into the mixture solution of the bismuth nitrate pentahydrate, the dilute nitric acid solution and the cetyl ammonium bromide, stirring, performing ultrasonic centrifugal washing, and then performing drying treatment, drying Carry out heat treatment in muffle furnace after treatment, obtain light yellow sample;

[...

Embodiment 1

[0105] 1) Get the 20ml dilute nitric acid solution that 0.2g bismuth nitrate pentahydrate dissolves, then add 0.1g cetyl ammonium bromide, obtain bismuth nitrate pentahydrate, dilute nitric acid solution and cetyl ammonium bromide after magnetic stirring for 20min mixture solution;

[0106] 2) Mix 200ml (2mol·L -1 ) Sodium hydroxide solution is added to the mixture solution of bismuth nitrate pentahydrate, dilute nitric acid solution and cetyl ammonium bromide, after stirring for 30min, ultrasonic centrifugal washing is carried out, and then drying treatment is carried out in a muffle furnace after drying treatment. Heat treatment to obtain a light yellow sample;

[0107] 3) Weigh 0.5g of light yellow sample and 0.5g of polyvinylpyrrolidone into a 100ml beaker filled with 50ml of deionized water, stir magnetically at room temperature to obtain a white mixture solution;

[0108] 4) Add 15ml of sodium borohydride (50mmol) solution dropwise to the white mixture solution, magnet...

Embodiment 2

[0113] 1) Get the 20ml dilute nitric acid solution that 0.2g bismuth nitrate pentahydrate dissolves, then add 0.1g cetyl ammonium bromide, obtain bismuth nitrate pentahydrate, dilute nitric acid solution and cetyl ammonium bromide after magnetic stirring for 20min mixture solution;

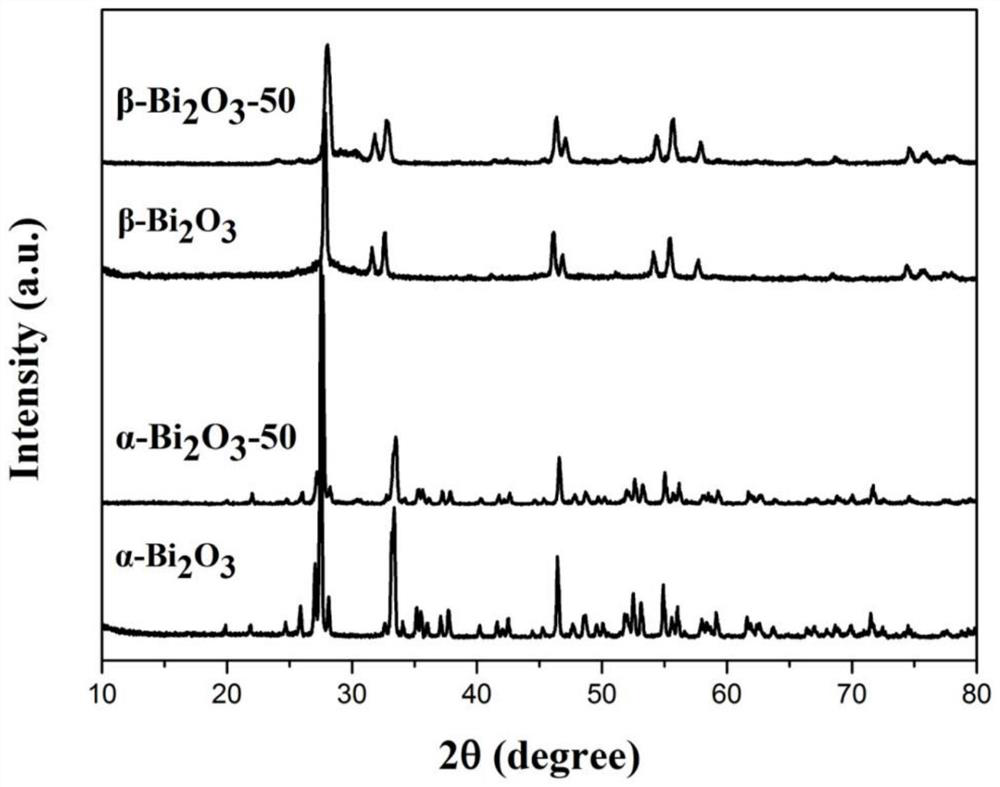

[0114] 2) Mix 200ml (2mol·L -1 ) Sodium hydroxide solution is added to the mixture solution of bismuth nitrate pentahydrate, dilute nitric acid solution and cetyl ammonium bromide, after stirring for 30min, ultrasonic centrifugal washing is carried out, and then drying treatment is carried out in a muffle furnace after drying treatment. Heat treatment to obtain pure monoclinic bismuth oxide photocatalyst (α-Bi 2 o 3 ).

[0115] The pure monoclinic bismuth oxide photocatalyst (α-Bi 2 o 3 ) and the degradation test process of NO are the same as in Example 1. Calculate the pure monoclinic bismuth oxide photocatalyst (α-Bi 2 o 3 ) to NO degradation rate of 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com