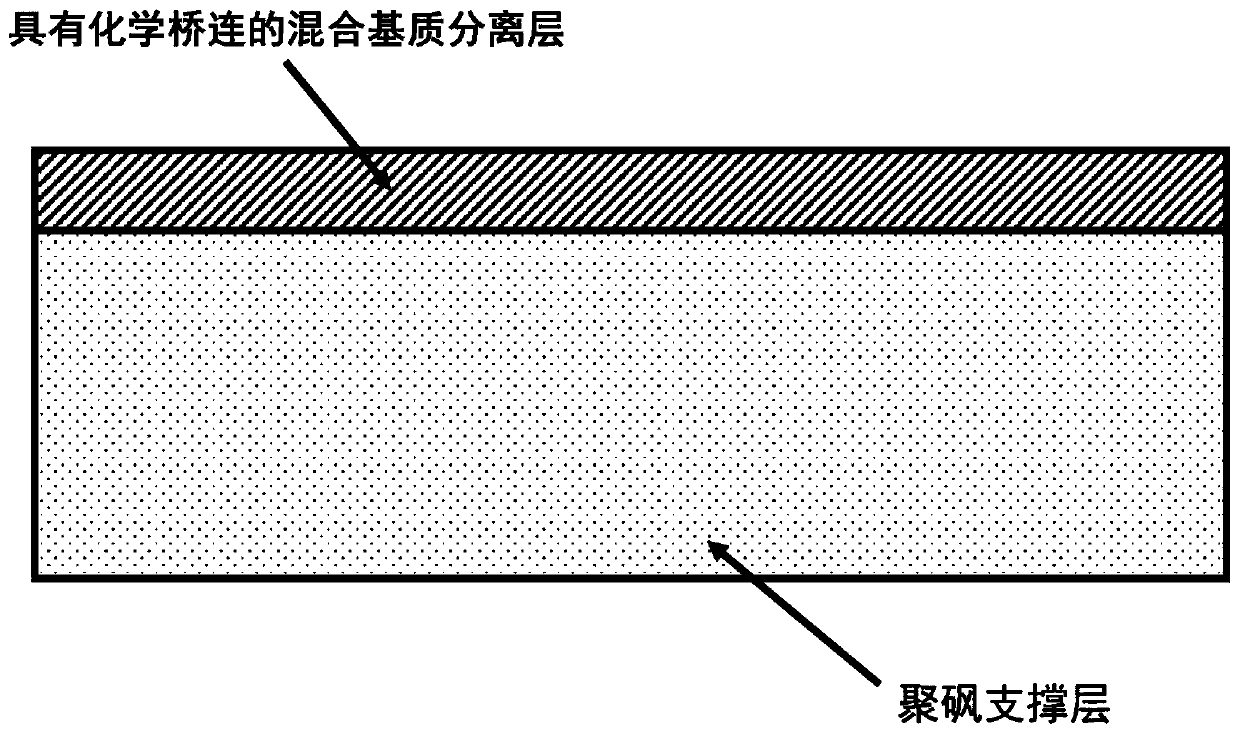

Method for preparing mixed matrix membranes for carbon dioxide separation by chemical bridging

A technology of mixed matrix membrane and carbon dioxide, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of low permeation selectivity and weak interface force of separation membranes, and achieve simple preparation process and short operation time Effect of short, excellent permeation selectivity properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1)N 2 protected, the UIO-66-NH 2 Add the powder into n-decyl alcohol to form a solution with a concentration of 12.5g / L, disperse and stir and ultrasonically uniform; add excess PEGDE dropwise to UIO-66-NH 2 In dispersion, N 2 Under protected conditions, the temperature of the dispersion was raised to 115° C. through an oil bath, and the reaction was carried out for 40 hours.

[0031] (2) Finally, excess unreacted PEGDE and solvent n-decanol were washed with methanol, and washed by centrifugation. The solid obtained by centrifugation was dried in vacuo to obtain PEG-UIO-66-NH 2 .

[0032] (3) PEG-UIO-66-NH obtained in step 2 2Nanoparticles dispersed in 1wt% polyvinylamine aqueous solution, PEG-UIO-66-NH 2 The amount of nanoparticles added is configured as 10wt%, N 2 Under protection, heat at 65°C in an oil bath and stir for 20 min to obtain a light yellow dispersion.

[0033] (4) Apply the dispersion in step 3 on the polysulfone ultrafiltration membrane, and dr...

Embodiment 2

[0036] (1)N 2 protected, the UIO-66-NH 2 Add the powder into n-decyl alcohol to form a solution with a concentration of 12.7g / L, disperse, stir and ultrasonically homogenize. Add excess PEGDE dropwise to UIO-66-NH 2 In dispersion, N 2 Under the condition of protection, the temperature of the dispersion liquid was raised to 120° C. through an oil bath, and the reaction was carried out for 45 hours.

[0037] (2) Finally, excess unreacted PEGDE and solvent n-decanol were washed with methanol, and washed by centrifugation. The solid obtained by centrifugation was dried in vacuo to obtain PEG-UIO-66-NH 2 .

[0038] (3) PEG-UIO-66-NH obtained in step 2 2 Nanoparticles dispersed in 1wt% polyvinylamine aqueous solution, PEG-UIO-66-NH 2 The amount of nanoparticles added is configured as 20wt%, N 2 Under protection, heat at 70°C in an oil bath and stir for 23 minutes to obtain a light yellow dispersion.

[0039] (4) Apply the dispersion liquid obtained in step 3 on the polysulf...

Embodiment 3

[0042] (1)N 2 protected, the UIO-66-NH 2 Add the powder into n-decyl alcohol to form a solution with a concentration of 12.8g / L, disperse, stir and ultrasonically homogenize. Add excess PEGDE dropwise to UIO-66-NH 2 In dispersion, N 2 Under protected conditions, the temperature of the dispersion was raised to 123° C. through an oil bath, and the reaction was carried out for 48 hours.

[0043] (2) Finally, excess unreacted PEGDE and solvent n-decanol were washed with methanol, and washed by centrifugation. The solid obtained by centrifugation was dried in vacuo to obtain PEG-UIO-66-NH 2 .

[0044] (3) PEG-UIO-66-NH obtained in step 2 2 Nanoparticles dispersed in 1wt% polyvinylamine aqueous solution, PEG-UIO-66-NH 2 The amount of nanoparticles added is configured as 30wt%, N 2 Under protection, heat at 73°C in an oil bath and stir for 27 minutes to obtain a light yellow dispersion.

[0045] (4) Apply the dispersion liquid obtained in step 3 on the polysulfone ultrafiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com