Preparation method of separation membrane material polyvinylamine for capturing carbon dioxide

A technology based on polyvinylamine and carbon dioxide, applied in separation methods, chemical instruments and methods, and semipermeable membrane separation, can solve problems such as low permeation selectivity and few functional groups in separation membrane materials, and achieve excellent permeation selectivity , Excellent CO2 permeation rate, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

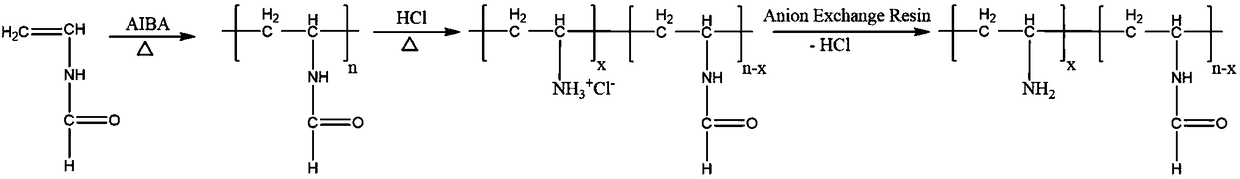

[0024] One for capturing CO 2 The preparation method of separation membrane material polyvinylamine, the steps are as follows:

[0025] 1) N-vinyl formamide (NVF) with a purity of 99% is configured into an aqueous solution with a concentration of 20 to 50 wt%, and the concentration of the initiator azobisisobutylamidine hydrochloride (AIBA) is 0.038 to 0.6 mg / L, add to the reaction device after stirring evenly, N 2 Polymerization at a constant temperature of 50-70°C under protection for 4-10 hours;

[0026] 2) Add excessive hydrochloric acid solution, fully carry out hydrolysis reaction;

[0027] 3) Add the hydrolyzed polymer solution dropwise to excess ethanol, and obtain PVAm.HCl (polyvinylamine hydrochloride) through ethanol precipitation;

[0028] 4) Dissolve the obtained precipitate with deionized water to prepare a 2wt% aqueous solution, then add an excessive amount of anion exchange resin, stir evenly, the solution is found to be alkaline, and filter it with a G3 gl...

Embodiment 1

[0031] 0.11kg of NVF with a purity of 99% is configured into an aqueous solution with a concentration of 20wt% at room temperature, and the concentration of the initiator azobisisobutylamidine hydrochloride (AIBA) is 0.6mg / L. After stirring evenly, add it to a 3L reactor device , N 2 Polymerize at a constant temperature of 70°C under protection for 4 hours; add excess hydrochloric acid solution to fully hydrolyze; add the hydrolyzed polymer solution dropwise to excess ethanol, and obtain PVAm.HCl by ethanol precipitation; then use deionized Dissolve in water and make 2wt% aqueous solution, then add excess strong basic styrene-type anion exchange resin, stir evenly, measure the solution is alkaline (pH=10), filter with G3 glass sand core funnel, get 2wt% PVAm aqueous solution.

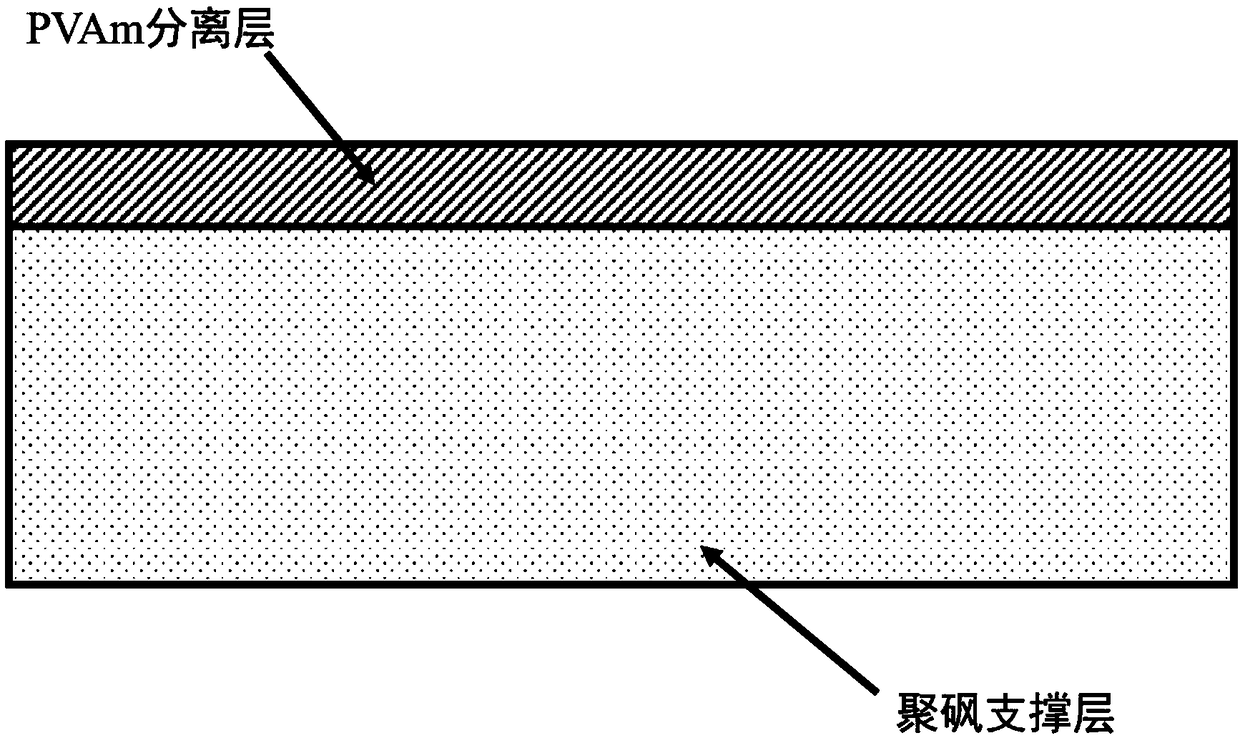

[0032] The 1wt% PVAm aqueous solution is scrape-coated on the polysulfone ultrafiltration membrane, and the obtained membrane is dried under constant temperature and humidity to obtain a high-performan...

Embodiment 2

[0035] 0.12kg of NVF with a purity of 99% is configured into an aqueous solution with a concentration of 20wt% at room temperature, and the concentration of the initiator azobisisobutylamidine hydrochloride (AIBA) is 0.076mg / L. After stirring evenly, add it to a 3L reactor device , N2 Polymerization at a constant temperature of 70°C under protection for 4 hours. Add excess hydrochloric acid solution, fully hydrolyzed. Add the hydrolyzed polymer solution dropwise to excess ethanol, and obtain PVAm.HCl through ethanol precipitation. Then the precipitate obtained is dissolved in deionized water and is mixed with a 2wt% aqueous solution, then an excessive amount of anion exchange resin (strongly basic styrene type anion exchange resin) is added, stirred evenly, and the solution is alkaline (pH = 10.3), filter with G3 glass sand core funnel to obtain 2wt% PVAm aqueous solution.

[0036] The 1wt% PVAm aqueous solution is scrape-coated on the polysulfone ultrafiltration membrane, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com