Carbon dioxide separating membrane having both primary amine and carbonate and preparation method thereof

A carbonate, primary amine-based technology, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of limited effect of functional carriers, and achieve the effect of simple, easy and low-cost membrane production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

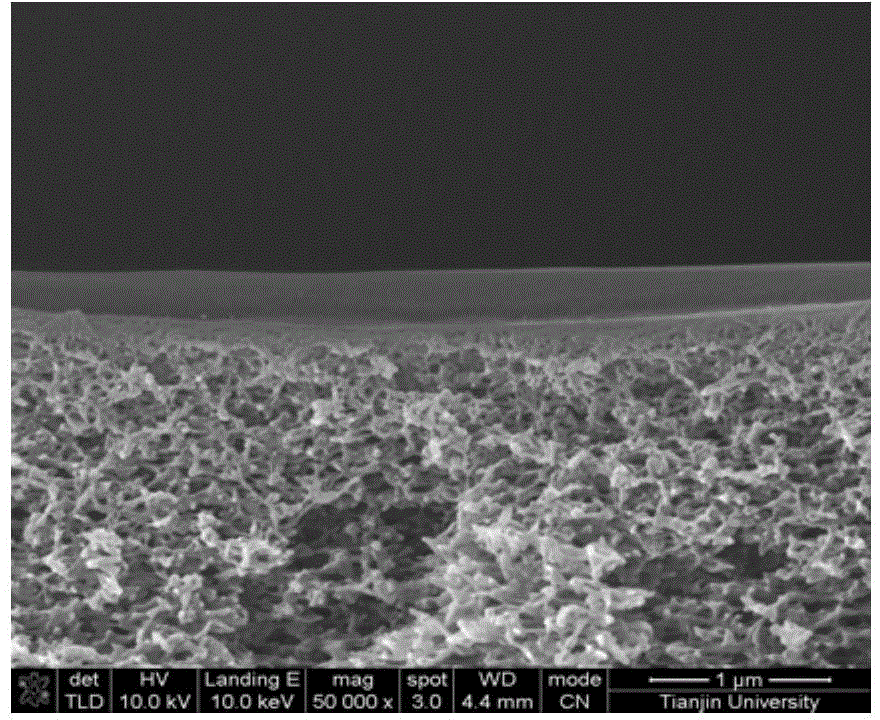

Image

Examples

Embodiment 1

[0024] Add 8.0g N-vinylformamide and 2.0g diallyldimethylammonium chloride to 40g deionized water, stir evenly to prepare a monomer solution with a mass fraction of 20%, and then add azo to the solution Diisobutyramidine hydrochloride. After thorough stirring, the solution was transferred to a flask equipped with a condenser, and the polymerization was carried out under nitrogen protection. After the polymerization reaction was completed, hydrochloric acid solution was added to the reaction system, and the hydrolysis reaction was carried out under nitrogen protection. The solution obtained by the hydrolysis reaction was added to ethanol, and the precipitated product was dissolved in deionized water and stirred thoroughly. Add strong basic anion exchange resin to the solution, carry out suction filtration treatment after fully stirring, and add ammonium carbonate to the solution obtained by suction filtration. After thorough stirring, dialysis treatment is performed, and the ...

Embodiment 2

[0028] Take 2.0g of N-vinylformamide and 8.0g of diallyldimethylammonium chloride and add it to 40g of deionized water, stir evenly to prepare a monomer solution with a mass fraction of 20%, and then add azobis to the solution. isobutyramidine hydrochloride. After thorough stirring, the solution was transferred to a flask equipped with a condenser, and the polymerization was carried out under nitrogen protection. After the polymerization reaction was completed, hydrochloric acid solution was added to the reaction system, and the hydrolysis reaction was carried out under nitrogen protection. The solution obtained by the hydrolysis reaction was added to ethanol, and the precipitated product was dissolved in deionized water and stirred thoroughly. Add strong basic anion exchange resin to the solution, carry out suction filtration treatment after fully stirring, and add ammonium carbonate to the solution obtained by suction filtration. After thorough stirring, dialysis treatment...

Embodiment 3

[0032] Take 6.0g of N-vinylformamide and 3.0g of diallyldimethylammonium chloride and add it to 36g of deionized water, stir evenly to prepare a monomer solution with a mass fraction of 20%, and then add azobis to the solution. isobutyramidine hydrochloride. After thorough stirring, the solution was transferred to a flask equipped with a condenser, and the polymerization was carried out under nitrogen protection. After the polymerization reaction was completed, hydrochloric acid solution was added to the reaction system, and the hydrolysis reaction was carried out under nitrogen protection. The solution obtained by the hydrolysis reaction was added to ethanol, and the precipitated product was dissolved in deionized water and stirred thoroughly. Add strong basic anion exchange resin to the solution, carry out suction filtration treatment after fully stirring, and add ammonium carbonate to the solution obtained by suction filtration. After thorough stirring, dialysis treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com