An etching method for improving the etching ability of the end face of a semiconductor silicon wafer

A technology for semiconductors and silicon wafers, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of uneven corrosion, cost loss, and inconsistent corrosion rate on the end surface of silicon wafers, and achieve the reduction of SiO2 film residue on the end surface, The effect of saving usage and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

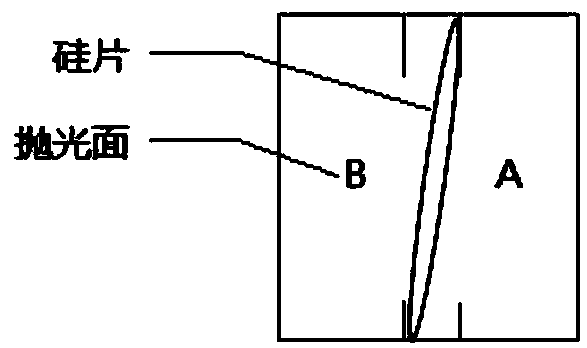

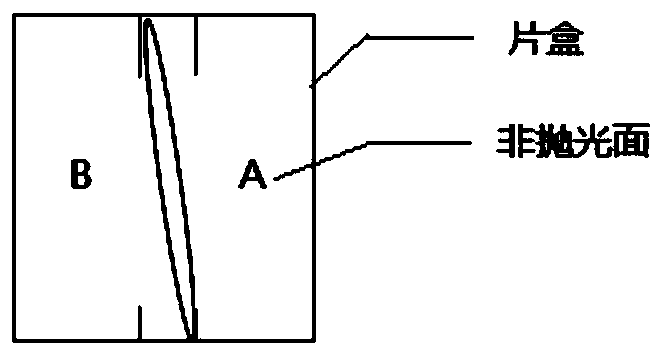

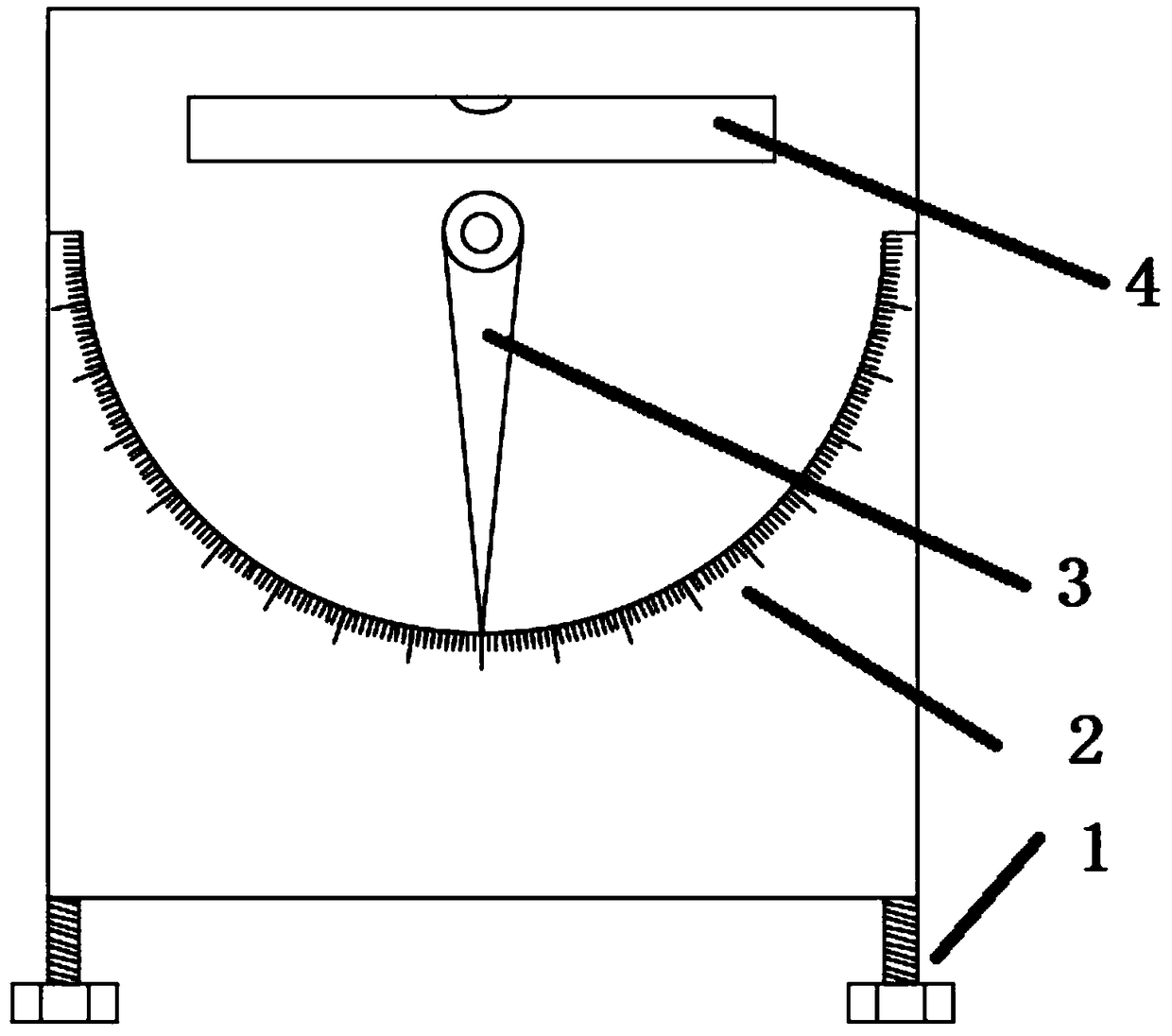

[0047] see image 3 , Figure 4 as well as Figure 5 , an etching method for improving the corrosion ability of semiconductor silicon wafer end faces, comprising the following steps: step 1, silicon wafers are loaded into a cassette, and the orientations of the polished surfaces of the silicon wafers in the cassette are consistent; The bottom plate of the treatment tank where the chip is corroded is set at an inclination, and the inclination angle formed by the bottom plate and the horizontal plane ranges from 1 to 10°; the four corners of the treatment tank are provided with threaded holes that open downward, and screws are installed in the threaded holes. , adjust the inclination of the bottom plate of the processing tank by screwing the screw into the threaded hole; Step 3, place the cassette in the processing tank, because the bottom plate of the processing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com