Corrosion resistant casing, arrangement scheme and application

A technology of anti-corrosion casing and layout scheme, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., and can solve problems such as service life of invalid anodes, crevice corrosion anodes, and anode materials that cannot be seamlessly connected, so as to prolong the service life, Effect of reducing uneven corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

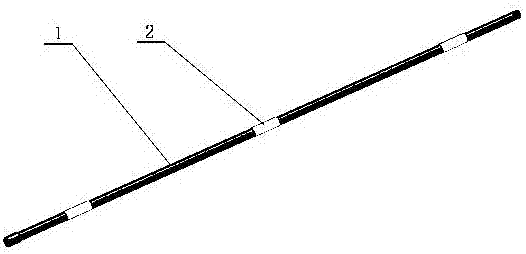

[0018] In order to solve the problems that the traditional anode material pre-cast according to the outer diameter of the casing cannot be tightly and seamlessly connected with the outer wall of the casing, the crevice corrosion causes anode failure and the anode has a short service life. figure 1 The anti-corrosion casing shown includes a casing 1, and a melted zinc anode 2 is cast on the outer surface of the casing 1, and the length of the zinc anode 2 along the axial direction is 500 mm.

[0019] The working principle of the anti-corrosion casing provided in this embodiment is:

[0020] After the zinc anode 2 is melted, it is directly cast on the outer surface of the sleeve 1 to make the anti-corrosion sleeve. The zinc anode 2 and the casing 1 are seamlessly and tightly conductively connected, and the zinc anode 2 provides a stable and continuous protection current, which effectively reduces the anode failure caused by uneven corrosion and crevice corrosion of the anode mat...

Embodiment 2

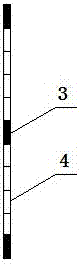

[0022] On the basis of Example 1, the zinc anode 2 is axially distributed at the front, middle and rear ends of the casing 1, the zinc anode 2 at the front end is 1000 mm away from the thread at the end of the casing 1, and the zinc anode at the rear end is Anode 2 is 1000mm away from casing 1 end collar.

[0023] Zinc anodes 2 are distributed at the front, middle and rear ends of the casing 1, and the front and rear are 1000mm away from the thread and the coupling respectively, so as to ensure that the hydraulic pipe wrench, elevators, clamps, etc. The normal use of tools such as tiles.

Embodiment 3

[0025] On the basis of Example 2, the outer diameter of the zinc anode 2 is 0.3 mm to 0.5 mm larger than the outer diameter of the collar of the casing 1 .

[0026] The outer diameter of the zinc anode 2 is close to the outer diameter of the collar of the casing 1. During the running of the anti-corrosion casing, the well wall does not wear the surface of the anode, ensuring the normal running of the anti-corrosion casing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com