Directional high thermal conductivity uranium dioxide pellet and preparation method thereof

A technology of uranium dioxide and high thermal conductivity, which is applied in the manufacture of reactors, reactor fuel elements, nuclear power generation, etc., can solve problems such as safety accidents, low radial thermal conductivity, and low thermal conductivity, so as to improve safety and improve Radial thermal conductivity, the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

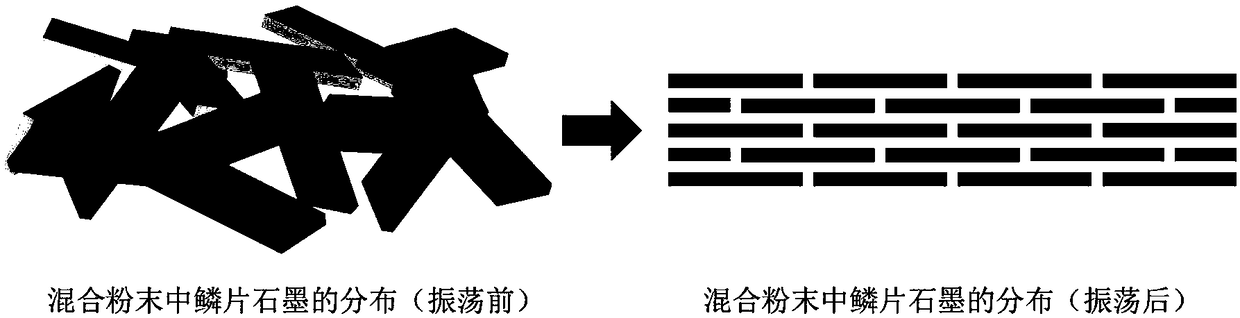

[0025] This embodiment provides the preparation method of the directional high thermal conductivity uranium dioxide pellet of the present invention, which can increase the radial thermal conductivity of the uranium dioxide pellet by more than 5%, and the axial thermal conductivity is almost unchanged. Specifically:

[0026] Raw material: uranium dioxide powder 235 The U enrichment degree is 1%, the oxygen-uranium ratio is 1.95, and the particle size is about 1 μm; the diameter of the flake graphite sheet is about 3 μm, and the thickness is about 1 μm.

[0027] Step 1. Put 98% volume fraction of uranium dioxide powder and 2% volume fraction of flake graphite into a mixing tank and mix for 24 hours at a speed of 200r / min.

[0028] Step 2. Carry out sintering as follows:

[0029] Put the mixed powder obtained in step 1 into a forming mold, vibrate on a vibrator for 0.1 h, and then mold it under a pressure of 100 MPa to obtain a green body. The green body is placed in a molybde...

Embodiment 2

[0032] This embodiment provides a method for preparing directional high thermal conductivity uranium dioxide pellets of the present invention, which can increase the radial thermal conductivity of the uranium dioxide pellets by more than 300%, and the axial thermal conductivity by more than 30%. Specifically:

[0033] Raw material: uranium dioxide powder 235 The U enrichment degree is 19%, the oxygen-uranium ratio is 2.15, and the particle size is about 50 μm; the diameter of the flake graphite sheet is about 200 μm, and the thickness is about 20 μm.

[0034] Step 1. Proportion the raw materials as follows:

[0035] Put 50% volume fraction of uranium dioxide powder and 50% volume fraction of flake graphite into a mixing tank and mix for 12 hours at a speed of 300r / min.

[0036] Step 2. Carry out sintering as follows:

[0037] Put the mixed powder obtained in step 1 into a forming mold, vibrate on a vibrator for 2 hours, and then mold it under a pressure of 500 MPa to obtain...

Embodiment 3

[0040] This embodiment provides the preparation method of the directional high thermal conductivity uranium dioxide pellet of the present invention, the method can increase the radial thermal conductivity of the uranium dioxide pellet by more than 60%, and the axial thermal conductivity by more than 10%. Specifically:

[0041] Raw material: uranium dioxide powder 235 The U enrichment degree is 10%, the oxygen-uranium ratio is 2.05, and the particle size is about 5 μm; the diameter of the flake graphite sheet is about 100 μm, and the thickness is about 5 μm.

[0042] Step 1. Proportion the raw materials as follows:

[0043] Put 90% volume fraction of uranium dioxide powder and 10% volume fraction of flake graphite into a mixing tank and mix for 4 hours at a speed of 300r / min.

[0044] Step 2. Carry out sintering as follows:

[0045] Put the mixed powder obtained in step 1 into a graphite mold, vibrate on an oscillator for 2 hours, and then carry out hot-press sintering. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com