A rapid evaluation method for low-cycle fatigue performance of ultra-thin automotive steel plates

A low-cycle fatigue, automotive steel plate technology, applied in the direction of strength characteristics, instruments, and the use of repetitive force/pulse force to test the strength of materials, etc., can solve the problems of the accuracy of the test results, the increase of material consumption, etc., to achieve a simple test process. Fast and cost-effective experimental material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

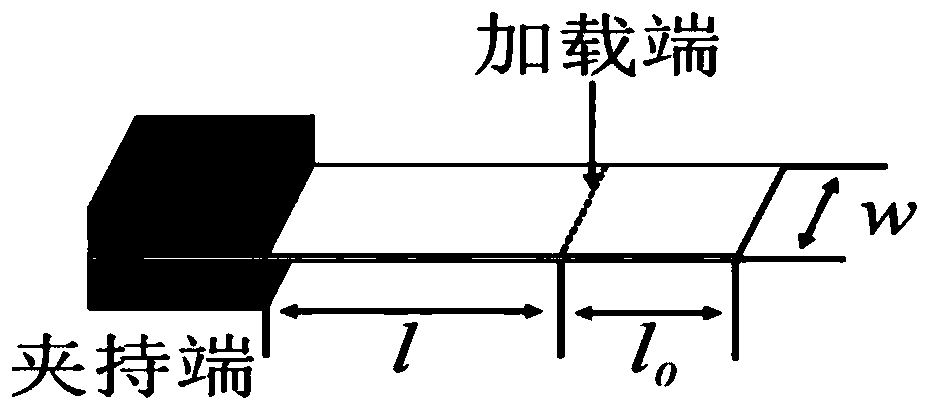

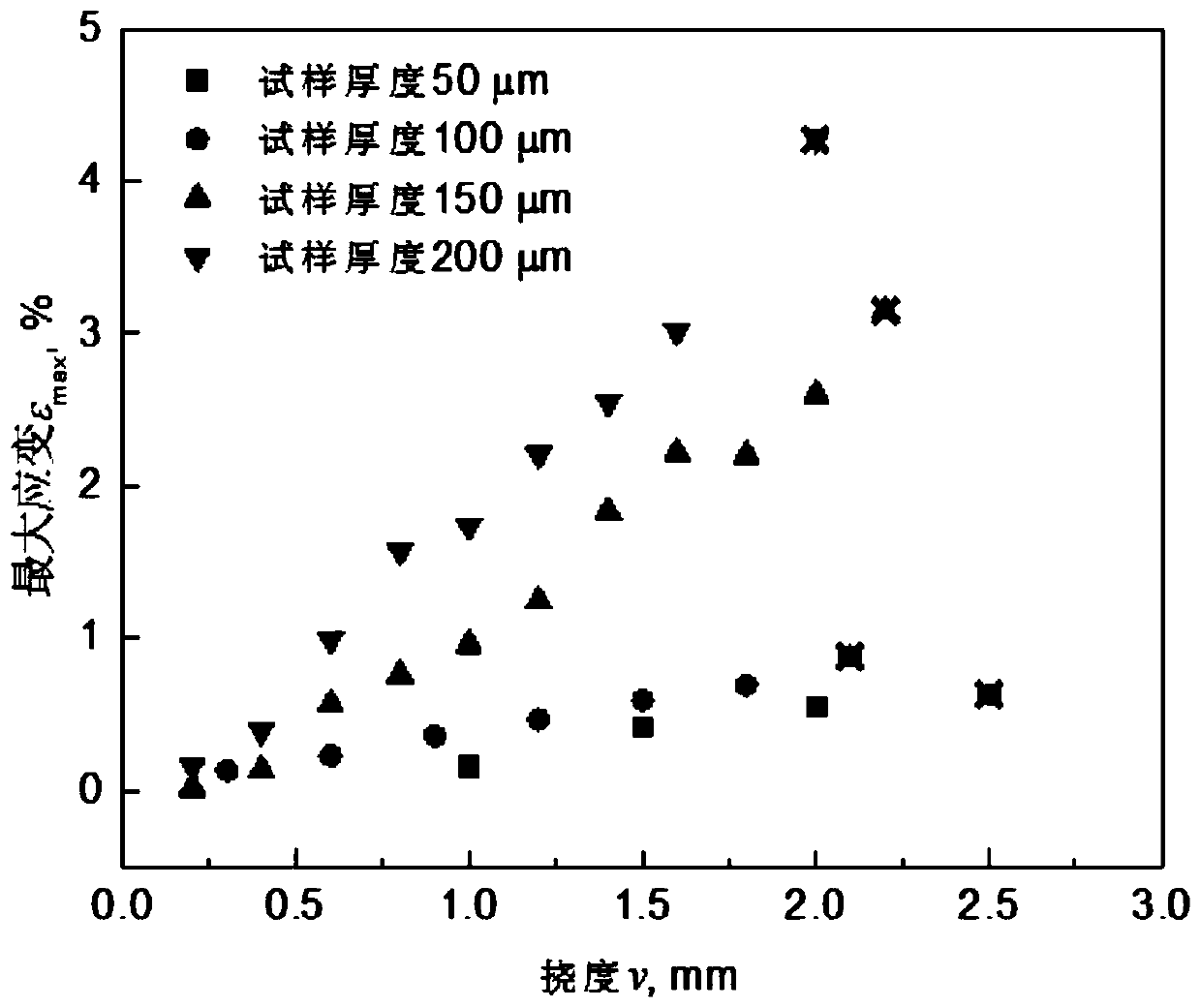

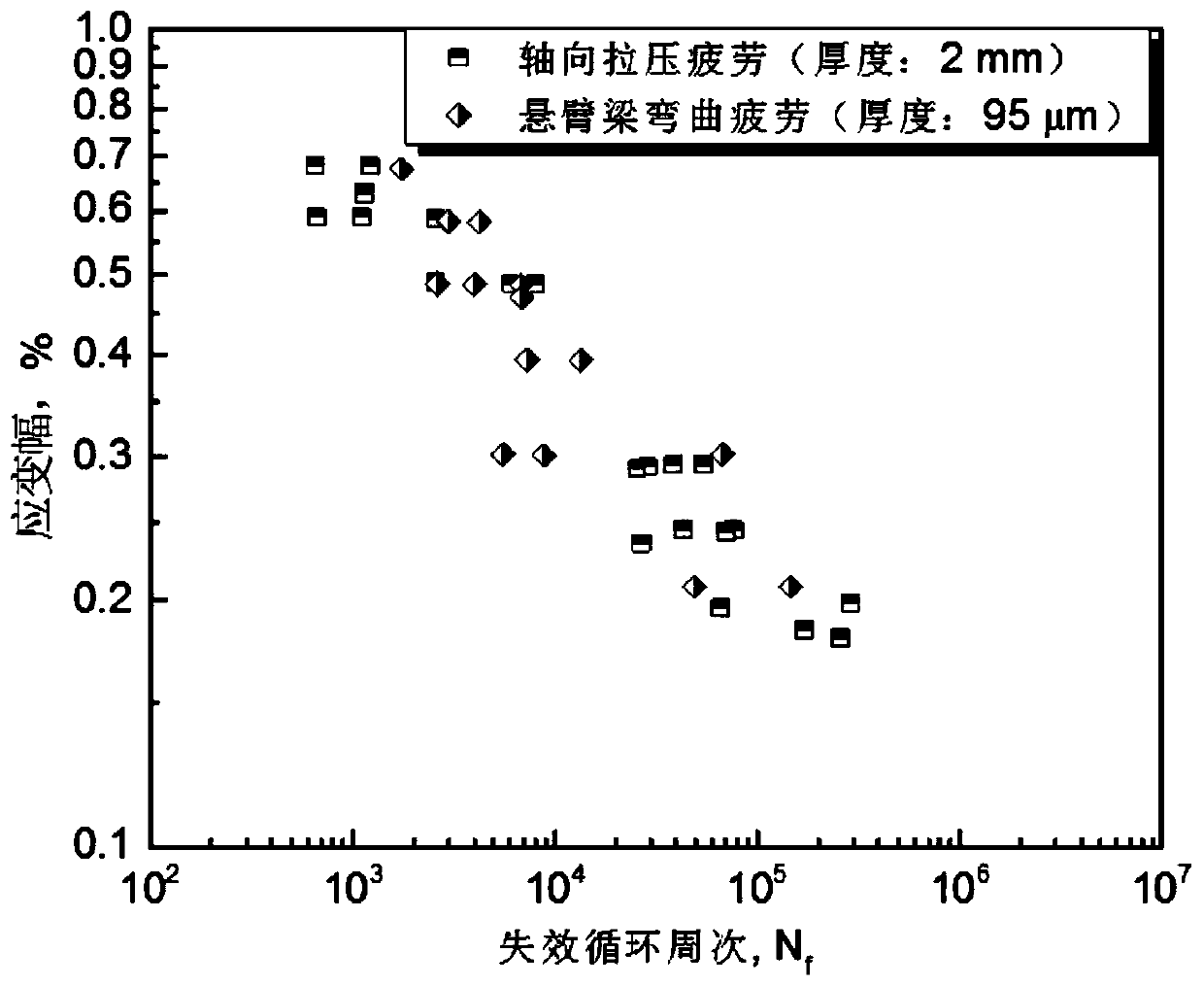

Embodiment 1

[0090] Carry out cantilever beam symmetrical bending fatigue loading on a DP590 steel sheet with an original thickness of 2 mm, determine the thickness range of the cantilever beam bending fatigue loading sample according to step S1, and design the thin foil size according to step S11: 1:11mm, l 0 : 3mm, w: 3.5mm, measure the average grain size of ferrite as d=9.5μm; calculate the number of grains passing through the first stage of fatigue crack propagation by step S12, Y≈1, σ y '≈400MPa, Δσ value is about 400~450MPa, calculated as i=3~4; from step S13, if the plate is subjected to tension-compression symmetric fatigue loading, calculate the number of grains that the crack propagates through in the second stage j≈2000 / 9.5≈210; combined with steps S14, S15 and S16, the value range of m is 2.5-4, and the calculated thickness range of the thin foil sample is t=60-160 μm. Then proceed to step S2, from step S21, select the thin foil thickness as 50 μm, 100 μm, 150 μm, 200 μm; est...

Embodiment 2

[0092] Carry out cantilever beam symmetrical bending fatigue loading on a DP steel sheet for automobiles with an original thickness of 2mm and a martensite volume fraction of 14%, determine the thickness range of the cantilever beam bending fatigue loading sample according to step S1, and design according to step S11 Thin foil size: l: 11mm, l 0 : 3mm, w: 3.5mm, measure the average grain size of ferrite as d=9.5μm; calculate the number of grains passing through the first stage of fatigue crack propagation by step S12, Y≈1, σ y '≈400MPa, Δσ value is about 400~450MPa, calculated as i=3~4; from step S13, if the plate is subjected to tension-compression symmetric fatigue loading, calculate the number of grains that the crack propagates through in the second stage j≈2000 / 9.5≈210; combined with steps S14, S15 and S16, the value range of m is 2.5-4, and the calculated thickness range of the thin foil sample is t=60-160 μm. Then proceed to step S2, from step S21, select thin foil th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com