Preparation method of chromium-free leather

A technology of chrome leather and tare weight, which is applied in the field of chrome-free leather preparation, can solve problems such as increased process complexity and environmental pollution, and achieve the effects of shortening the production cycle, reducing environmental pollution, and strong tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

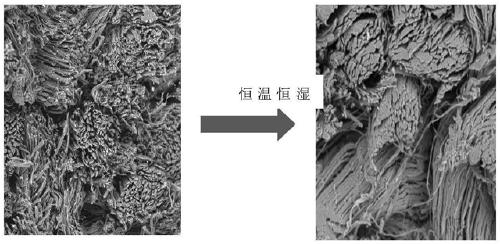

[0037](1) Solvent dehydration: first place the pickled skin in a drum, wash it with water to remove the salt, and then dehydrate the skin with a step-by-step dehydration method, that is, first use 400% absolute ethanol solution to dehydrate twice, each time 120min; Then use the mixed solution of 400% absolute ethanol and acetone (mass ratio is 1:1) to dehydrate 1 time, 120min; finally use 400% acetone solution to dehydrate 1 time, 120min, get the wet white skin with fiber dispersion at this time, recycle Organic solvents;

[0038] (2) Block the hydrophilic group: add tare 40% acetone, tare 4% IPDI trimer, rotate for 360 minutes, so that the IPDI trimer is well penetrated and reacted in the skin, and then recover the bath liquid;

[0039] (3) Drying: take out the treated leather from the drum, hang it to dry, and obtain the fiber-fixed chrome-free leather.

Embodiment 2

[0041] (1) Solvent dehydration: first place the pickled skin in a drum, wash it with water to remove the salt, and then dehydrate the skin with a step-by-step dehydration method, that is, first use 400% absolute ethanol solution to dehydrate twice, each time 120min; Then use the mixed solution of 400% absolute ethanol and acetone (mass ratio is 1:1) to dehydrate 1 time, 120min; finally use 400% acetone solution to dehydrate 1 time, 120min, get the wet white skin with fiber dispersion at this time, recycle Organic solvents;

[0042] (2) Block the hydrophilic group: add 40% tare acetone and 4% tare IPDI trimer, rotate for 360 min, and recover the bath liquid.

[0043] (3) Filling: Add 40% tare acetone and 10% tare white oil, rotate for 120min, and recover the bath liquid.

[0044] (4) Drying: The treated leather is taken out from the drum and dried in vacuum to obtain fiber-fixed chrome-free leather.

Embodiment 3

[0046] (1) Solvent dehydration: first place the softened skin in a drum, and then dehydrate the skin with a step-by-step dehydration method, that is, dehydrate with 400% absolute ethanol solution twice, each time for 120min; The mixed solution of water ethanol and acetone (mass ratio is 1:1) is dehydrated once for 120 minutes; finally, it is dehydrated once with 400% acetone solution for 120 minutes. At this time, wet white leather with fiber dispersion is obtained, and the organic solvent is recovered in each step;

[0047] (2) Block the hydrophilic group: add tare 100% acetone, tare 1.5% IPDI trimer, rotate for 60 min, then add tare 2.5% IPDI trimer, rotate for 240 min, and recover the bath liquid.

[0048] (3) Drying: The treated leather is taken out from the drum, and stretched to dry to obtain fiber-fixed chrome-free leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com