A wear-resistant luminescent resin glue, its preparation method and application

A technology of resin glue and luminescent powder, applied in luminescent paints, coatings, polyurea/polyurethane coatings, etc., can solve the problem of uneven surface of outdoor luminous tiles, weak adhesion between wear-resistant layers and coatings, and poor wear resistance for a long time. Maintenance and other issues, to achieve the effect of long-term maintenance of wear resistance, smooth surface and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

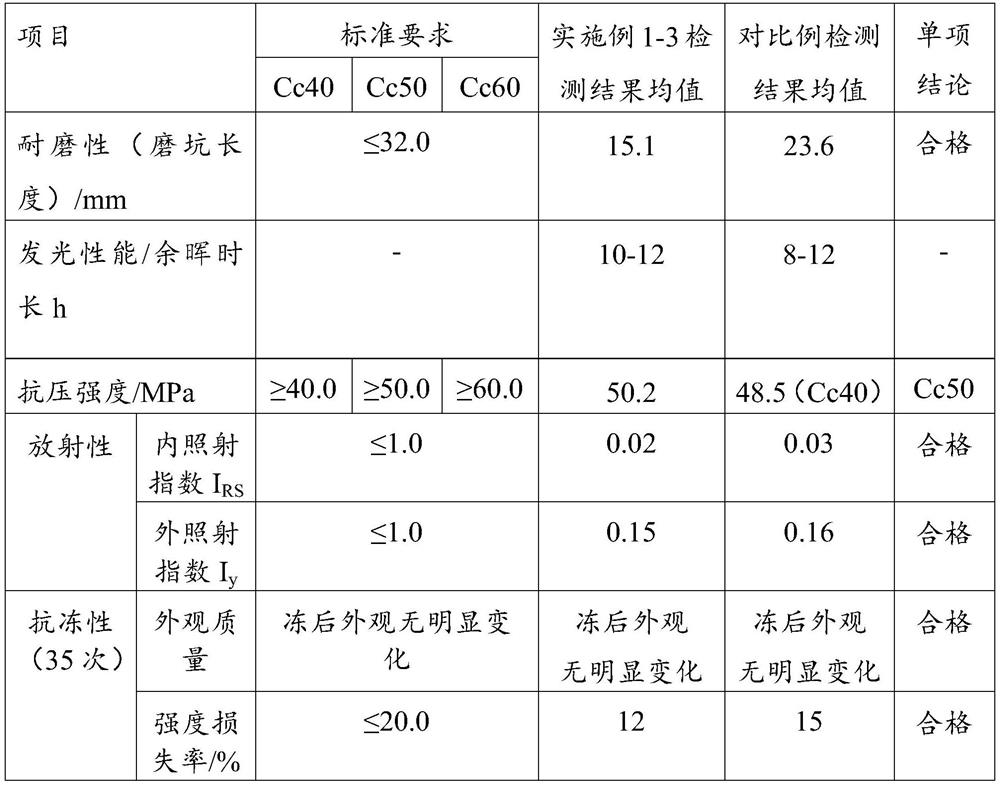

Examples

Embodiment 1

[0039] Wear-resistant luminous resin glue, comprising by weight:

[0040] 100 parts polyurea resin,

[0041] 100 parts of luminescent powder, the particle size is 200 mesh,

[0042] 30 parts of glass microspheres or glass microsand, particle size is 180 mesh,

[0043] 66 parts aliphatic polyisocyanate curing agent, and

[0044] 10 parts of additives;

[0045] The auxiliary agents include defoaming agent, drier, ultraviolet absorber, coupling agent and polyamide wax, and the weight ratio of the above auxiliary agents is 0.4:0.25:0.4:1.6:1.4.

[0046] The preparation method of the wear-resistant luminescent resin glue comprises the following steps:

[0047] (1) Add the polyamide wax to the polyurea resin while stirring at a speed of 700r / min, stir for 6 minutes until evenly stirred, and obtain a mixed raw material;

[0048] (2) Add glass microspheres or glass micro-sand and luminescent powder to the mixed raw material obtained in step (1), stir at a speed of 3000r / min for 2...

Embodiment 2

[0054] Wear-resistant luminous resin glue, comprising by weight:

[0055] 80 parts polyurea resin,

[0056] 110 parts of luminescent powder, the particle size is 80, mesh,

[0057] 10 parts of glass microspheres or glass sand, the particle size is 200 mesh

[0058] 80 parts aliphatic polyisocyanate curing agent, and

[0059] 5 parts of additives;

[0060] The auxiliary agents include defoaming agent, drier, ultraviolet absorber, coupling agent and polyamide wax, and the weight ratio of the above auxiliary agents is 0.5:0.1:0.5:1.3:1.6.

[0061] The preparation method of the wear-resistant luminescent resin glue comprises the following steps:

[0062] (1) Add the polyamide wax to the polyurea resin while stirring at a rotating speed of 500r / min, stir for 8 minutes until evenly stirred, and obtain a mixed raw material;

[0063] (2) Add glass microspheres or glass micro-sand and luminescent powder to the mixed raw material obtained in step (1), and stir at a speed of 2000r / min...

Embodiment 3

[0069] Wear-resistant luminous resin glue, comprising by weight:

[0070] 120 parts polyurea resin,

[0071] 90 parts of luminescent powder, the particle size is 300 mesh,

[0072] 50 parts of glass microspheres or glass microsand, particle size is 50 mesh,

[0073] 60 parts aliphatic polyisocyanate curing agent, and

[0074] 15 parts of additives;

[0075] The auxiliary agents include defoaming agent, drier, ultraviolet absorber, coupling agent and polyamide wax, and the weight ratio of the above auxiliary agents is 0.3:0.35:0.3:1.8:1.2.

[0076] The preparation method of the wear-resistant luminescent resin glue comprises the following steps:

[0077] (1) Add the polyamide wax to the polyurea resin while stirring at a rotating speed of 1000r / min, stir for 5 minutes until evenly stirred, and obtain a mixed raw material;

[0078] (2) Add glass microspheres or glass micro-sand and luminescent powder to the mixed raw material obtained in step (1), and stir at a speed of 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com