High temperature-resistant fireproof coating and preparation method thereof

A fire-resistant coating and high-temperature-resistant technology, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor mechanical properties and processing properties, corrosion of fire-resistant coatings to substrates, poor adhesion, etc., and achieve stable coating performance. Long fire time and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

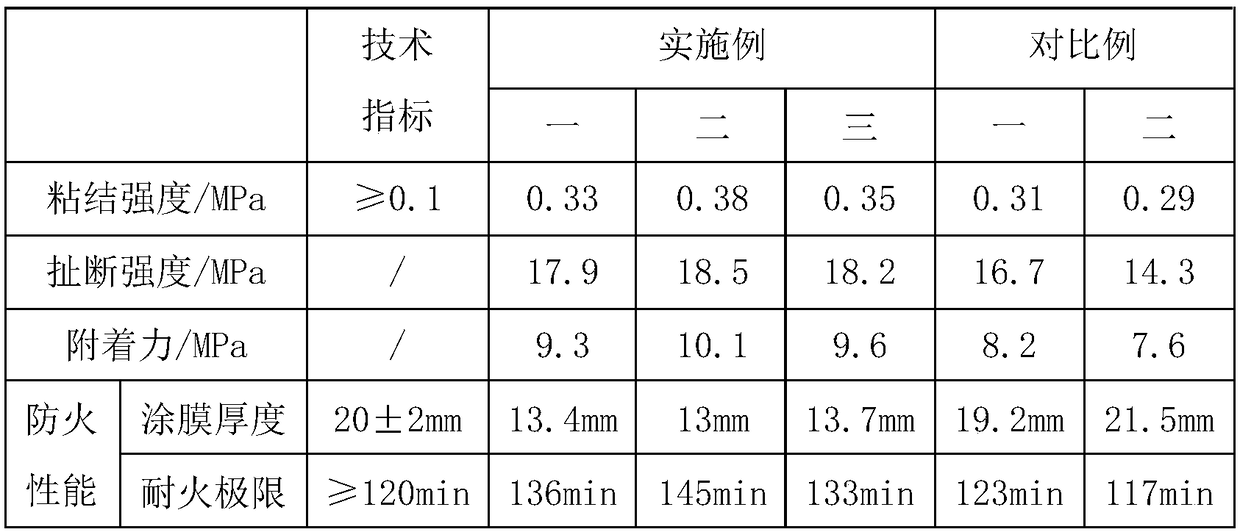

Examples

Embodiment 1

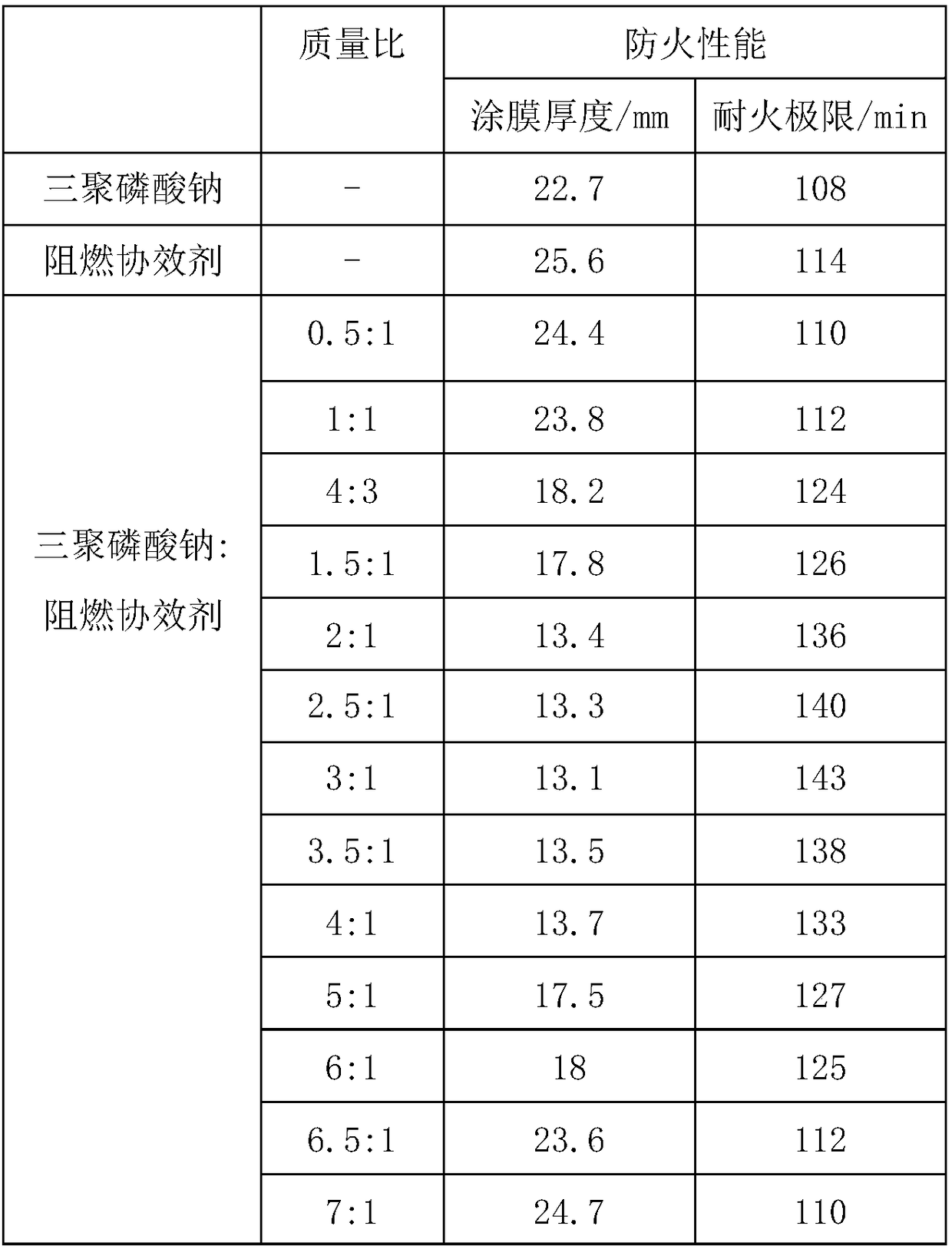

[0030] A high-temperature-resistant fireproof coating proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of composite base material resin, 18 parts of flame-retardant amino resin, 10 parts of polyvinyl acetate emulsion adhesive, 5 parts of titanium dioxide, and 5 parts of expanded vermiculite 4 parts of sodium tripolyphosphate, 2 parts of flame retardant synergist, 3 parts of butyl octadecenoate, 2 parts of additives;

[0031] Described flame-retardant amino resin is made by following method:

[0032] S1. Dissolve 3 parts by weight of urea in 35 parts by weight of deionized water, ultrasonically dissolve it fully, add 8 parts by weight of pentaerythritol, and stir at room temperature to form a solution I;

[0033] S2. Add 30 parts of melamine into solution I. After heating up to 90°C, add 10 parts by weight of magnesium hydroxide while stirring. After stirring evenly, cool down to 70°C, let stand for 1 hour, filter and dry to o...

Embodiment 2

[0046] A high-temperature-resistant fireproof coating proposed by the present invention includes the following raw materials in parts by weight: 70 parts of composite base material resin, 22 parts of flame-retardant amino resin, 13 parts of polyvinyl acetate emulsion adhesive, 7 parts of titanium dioxide, and 7 parts of expanded vermiculite 7.5 parts of sodium tripolyphosphate, 2.5 parts of flame retardant synergist, 5 parts of butyl octadecenoate, 3.5 parts of additives;

[0047] Described flame-retardant amino resin is made by following method:

[0048] S1. Dissolve 5 parts by weight of urea in 40 parts by weight of deionized water, ultrasonically dissolve it fully, add 12 parts by weight of pentaerythritol, and stir at room temperature to form a solution I;

[0049] S2. Add 35 parts of melamine into solution I. After heating up to 100°C, add 13 parts by weight of magnesium hydroxide while stirring. After stirring evenly, cool down to 78°C, let stand for 1.5h, and then filte...

Embodiment 3

[0062] A high-temperature-resistant fireproof coating proposed by the present invention comprises the following raw materials in parts by weight: 80 parts of composite base material resin, 25 parts of flame-retardant amino resin, 15 parts of polyvinyl acetate emulsion adhesive, 10 parts of titanium dioxide, and 10 parts of expanded vermiculite 12 parts, 12 parts of sodium tripolyphosphate, 3 parts of flame retardant synergist, 8 parts of butyl octadecenoate, 5 parts of additives;

[0063] Described flame-retardant amino resin is made by following method:

[0064] S1. Dissolve 8 parts by weight of urea in 45 parts by weight of deionized water, ultrasonically dissolve it fully, add 15 parts by weight of pentaerythritol, and stir at room temperature to form a solution I;

[0065] S2. Add 40 parts of melamine into solution I, heat up to 110°C, add 16 parts by weight of magnesium hydroxide while stirring, after stirring evenly, cool down to 85°C, let it stand for 2 hours, filter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com