Flexible lubricating coating as well as preparation method and application of flexible lubricating coating

A lubricating coating and flexible technology, applied in the field of flexible lubricating coating and its preparation, can solve the problems of difficult large-scale preparation, complex methods, high technical requirements, etc., and achieve durable and stable anti-icing performance, low ice adhesion strength, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

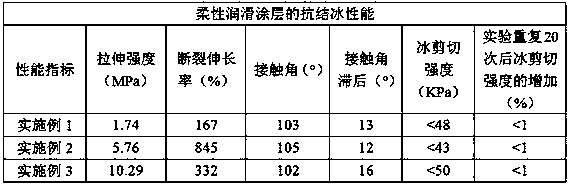

Examples

Embodiment 1

[0028] Preparation of tetrafluoropropyl norbornene carboxylic acid, the preparation method is: first tetrafluoropropanol 4.62g, 5-norbornene-2-carboxylic acid 5.53g, trimethylacetic anhydride 7.45g and 4-methylaminopyridine 42.76mg was dissolved in 50ml tetrahydrofuran, reacted at 50°C for 24 hours, and dissolved in saturated NaHCO 3 solution, saturated NaCl solution, washed with water, adding an appropriate amount of anhydrous MgSO 4 Dry, and then rotary evaporate to obtain light yellow viscous liquid.

[0029] Prepare tetrafluoropropyl norbornene carboxylate polymer. The preparation method is: first dissolve 3.03 g of tetrafluoropropyl norbornene carboxylate in 50 ml of dichloromethane in an ice bath, blow nitrogen to deoxygenate, and Grubbs second-generation catalyst (Grubbs 2 nd ) 50.94 mg dissolved in dichloromethane was injected into the reaction vial through a syringe, and the nitrogen gas was continued for 30 minutes. Evaporate to obtain the polymer.

[0030] Prepa...

Embodiment 2

[0033] To prepare octafluoropentyl norbornene carboxylic acid, the preparation method is: first, 8.12 g of octafluoropentyl ester, 5.53 g of 5-norbornene-2-carboxylic acid, 7.45 g of trimethylacetic anhydride and 4-methylaminopyridine 42.76mg was dissolved in 50ml tetrahydrofuran, reacted at 60°C for 18 hours, and was dissolved in saturated NaHCO 3 solution, saturated NaCl solution, washed with water, adding an appropriate amount of anhydrous MgSO 4 Dry, and then rotary evaporate to obtain light yellow viscous liquid.

[0034] Preparation of octafluoropentyl norbornene carboxylate polymer, the preparation method is as follows: first, 3.15 g of octafluoropentyl norbornene carboxylate is dissolved in 50 ml of dichloromethane in an ice bath, nitrogen gas is used to remove oxygen, and then the Grubbs second-generation catalyst (Grubbs 2 nd ) 37.99 mg dissolved in dichloromethane was injected into the reaction vial through a syringe, and the nitrogen gas was continued for 30 minu...

Embodiment 3

[0038] Preparation of cyclooctene perfluorooctyl ethyl ester: first, 6.50 g of 2-perfluorooctyl ethyl alcohol, 3.20 g of cyclooctene-4-mercapto-acetic acid, 2.98 g of trimethylacetic anhydride and 4-methylamino Dissolve 23mg of pyridine in 30ml of tetrahydrofuran, react at 70°C for 12 hours, and dissolve in saturated NaHCO 3 solution, saturated NaCl solution, washed with water, adding an appropriate amount of anhydrous MgSO 4 Dry, and then rotary evaporate to obtain light yellow viscous liquid.

[0039] Prepare the cyclooctene perfluorooctyl ethyl ester polymer, the preparation method is: first dissolve 5.58 g of cyclooctene perfluorooctyl ethyl ester in 50 ml of dichloromethane under ice bath, nitrogen gas deoxygenation, and then Grubbs 2nd generation catalyst (Grubbs 2 nd ) 36.71 mg dissolved in dichloromethane was injected into the reaction vial through a syringe, and the nitrogen gas was continued for 30 minutes. Evaporate to obtain the polymer.

[0040] Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com