Sludge drying coupled coal-fired power generation system and method

A technology for sludge drying and power generation system, which is applied in combustion methods, combined combustion mitigation, dewatering/drying/concentrating sludge treatment, etc. Cost increase and other issues, to achieve the effect of easy large-scale amplification, reducing system investment and operating costs, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific implementation examples.

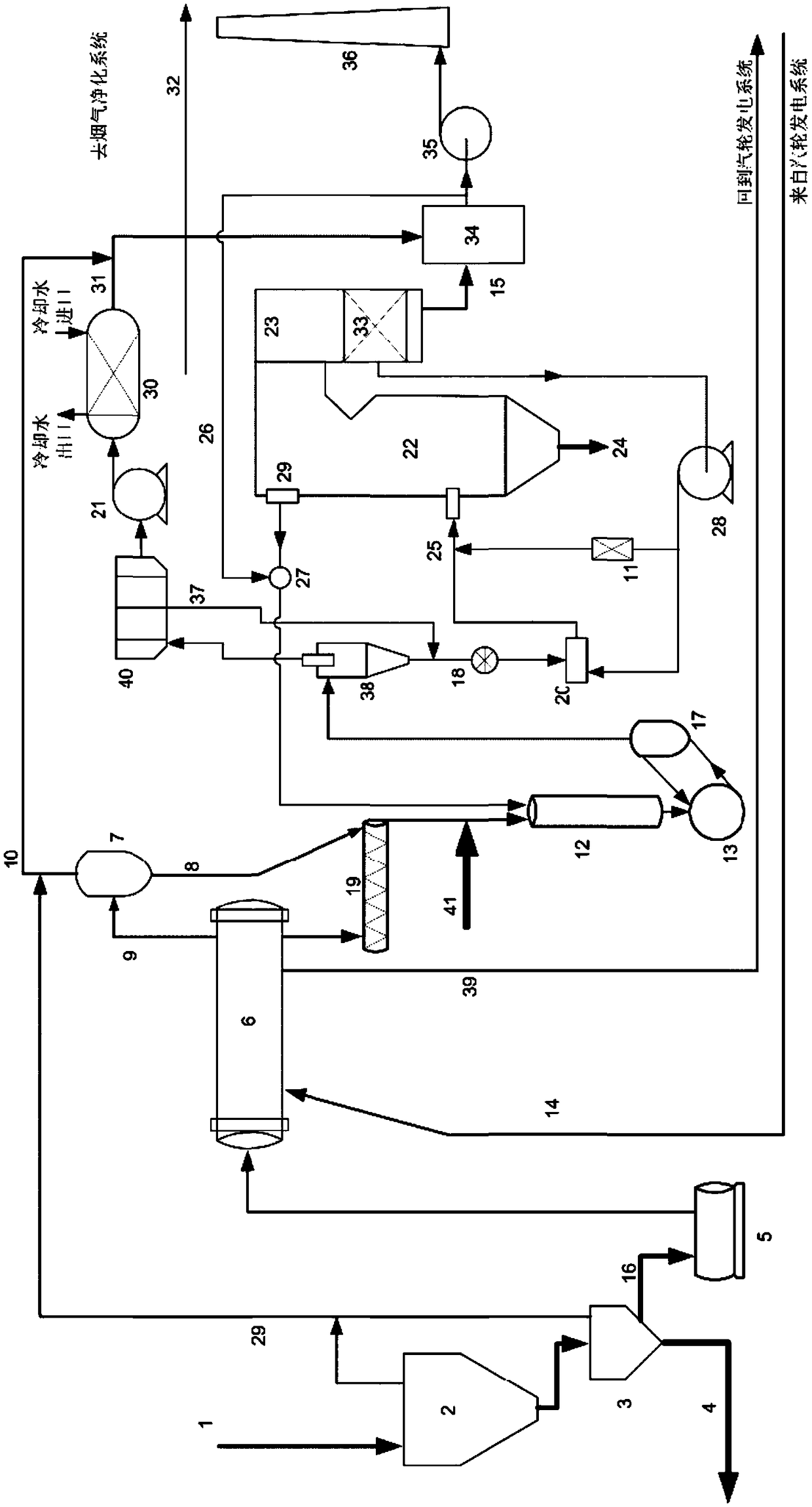

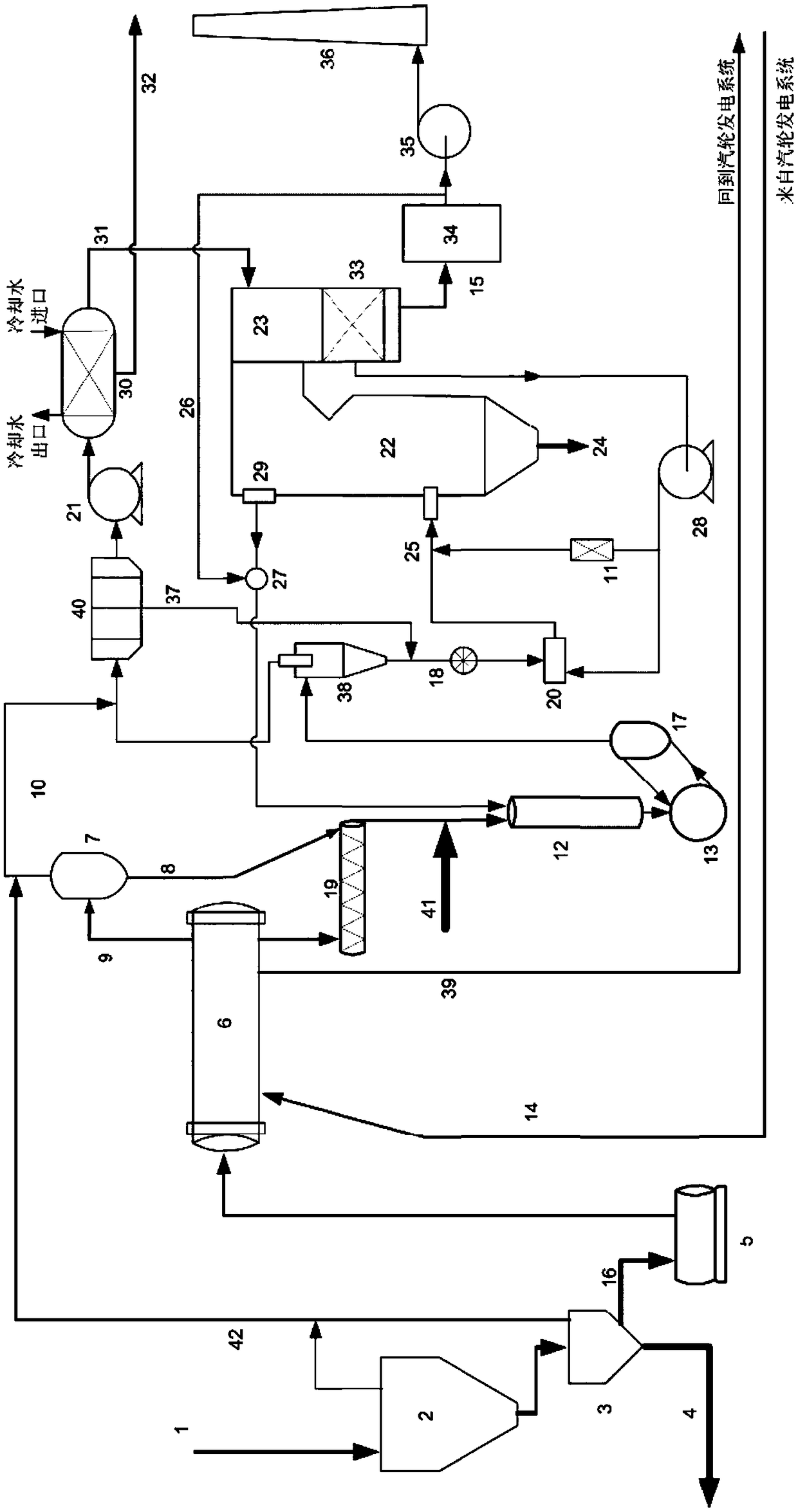

[0034] The invention provides a sludge drying coupling coal-fired power generation system, which fully utilizes the surplus low-grade flue gas and steam of the coal-fired boiler power generation system, uses the part of the heat source to dry the sludge and sends it to the boiler system for combustion.

[0035] figure 1A structural schematic diagram of a sludge drying coupled coal-fired power generation system provided in this embodiment, the sludge drying coupled coal-fired power generation system is mainly composed of a sludge pre-treatment dehydration unit and a sludge indirect drying unit , blending raw coal fan coal mill unit and exhaust gas purification treatment and other workshop equipment.

[0036] The sludge pretreatment dehydration unit mainly includes sludge raw material bin 2, mechanical dehydrator 3 and sludge pump 5, etc. In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com