Full-automatic four-edge banding equipment and method for plate

An edge banding equipment, fully automatic technology, applied in metal processing equipment, grinding/polishing equipment, household components, etc., can solve the problems of heavy equipment, high cost, poor automation, etc., to save manpower and material resources, and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

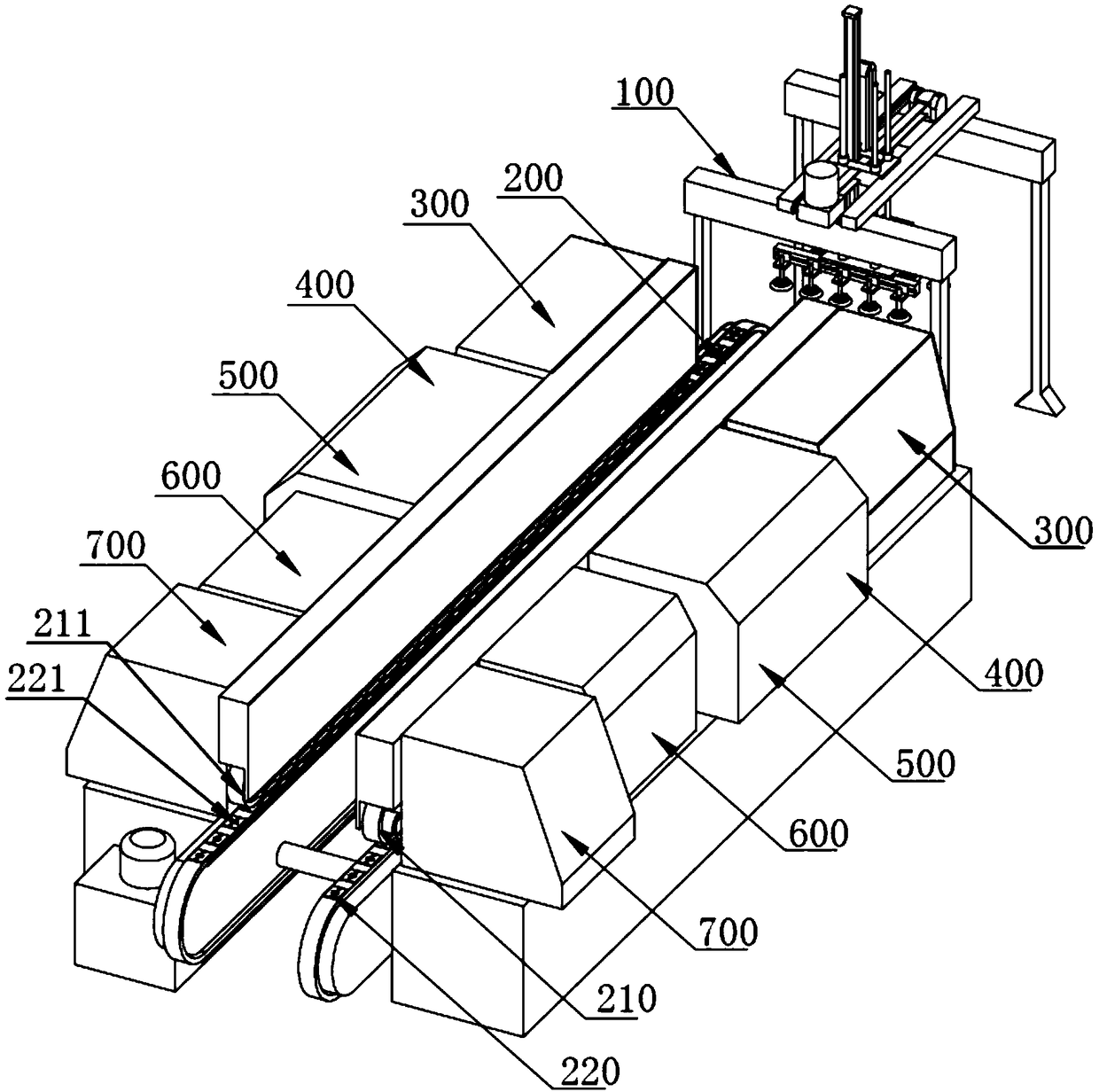

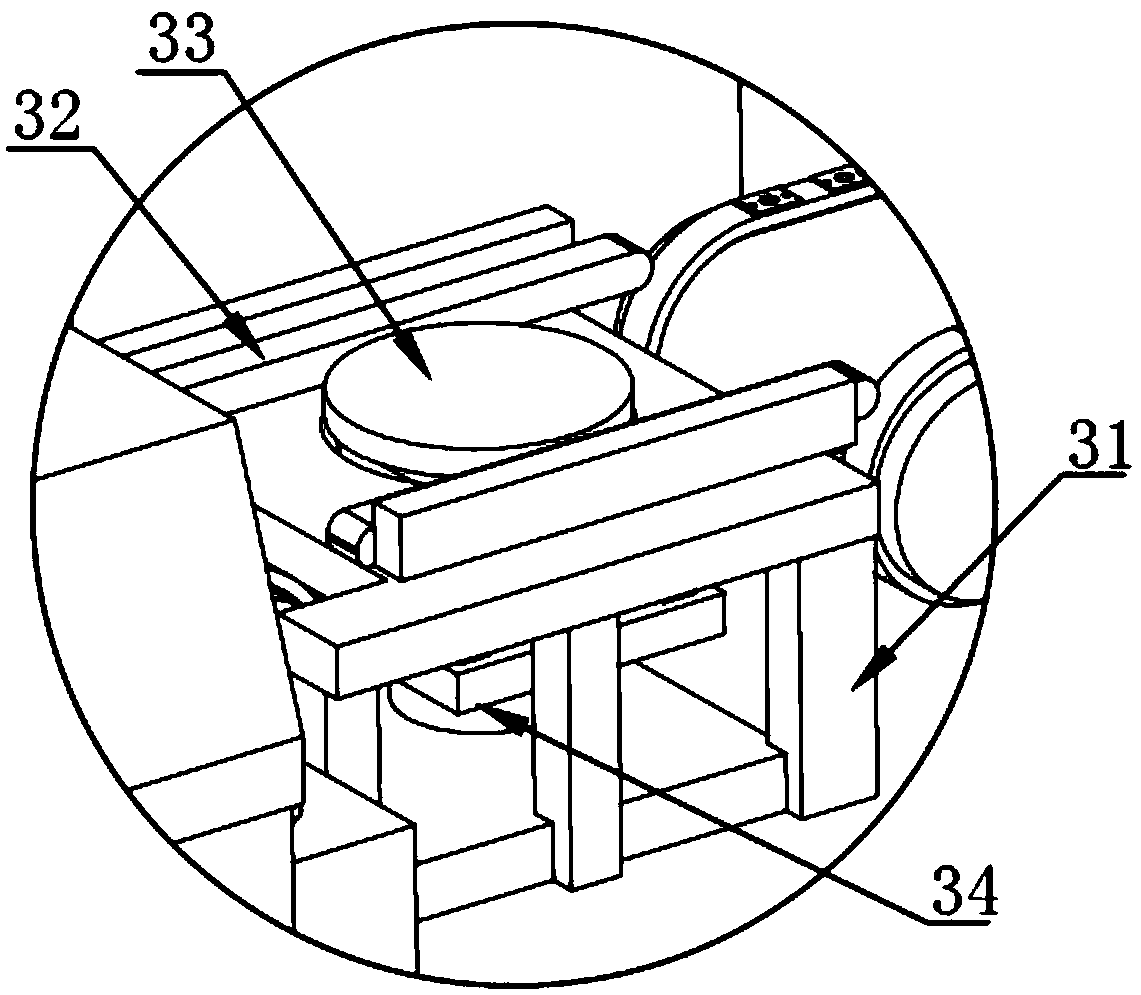

[0053] Such as Figure 1 ~ Figure 2 As shown, a fully automatic four-sided edge banding equipment for boards includes a feeding device 100 for grabbing and loading boards, a first edge banding mechanism 10 and a second edge banding mechanism 20, the first edge banding mechanism 10 and A turntable mechanism 30 is arranged between the second edge-sealing mechanisms 20 to connect, and the first edge-sealing mechanism 10 includes a conveying device 200 for grabbing the sheet material by the feeding device 100 and conveying it, a surface cutting device 300 for cutting the surface of the sheet material during the conveying process, The edge banding device 400 for sealing the edge of the cut surface, the edge trimming device 500 for trimming the edge banded plate, the polishing device 600 for polishing the trimmed plate, and the sanding device 700 for sanding the polished pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com