Industrial robot space intersecting curve welding offline programming method

An industrial robot and off-line programming technology, applied in welding equipment, welding accessories, manipulators, etc., can solve the problems of not supporting DXF and other workpiece model formats, poor human-computer interaction, and inability to solve complex weld curves of irregular workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0070] In order to verify the specific implementation of the present invention, a STEP SA1800 six-degree-of-freedom industrial robot with a fixed welding gun was used to conduct a saddle-shaped space curve welding experiment formed by two cylinders intersecting. The used intersecting cylinder has a radius of 150 mm for the main pipe and a radius of 100 mm for the branch pipes. The unit of each coordinate data shown below is mm.

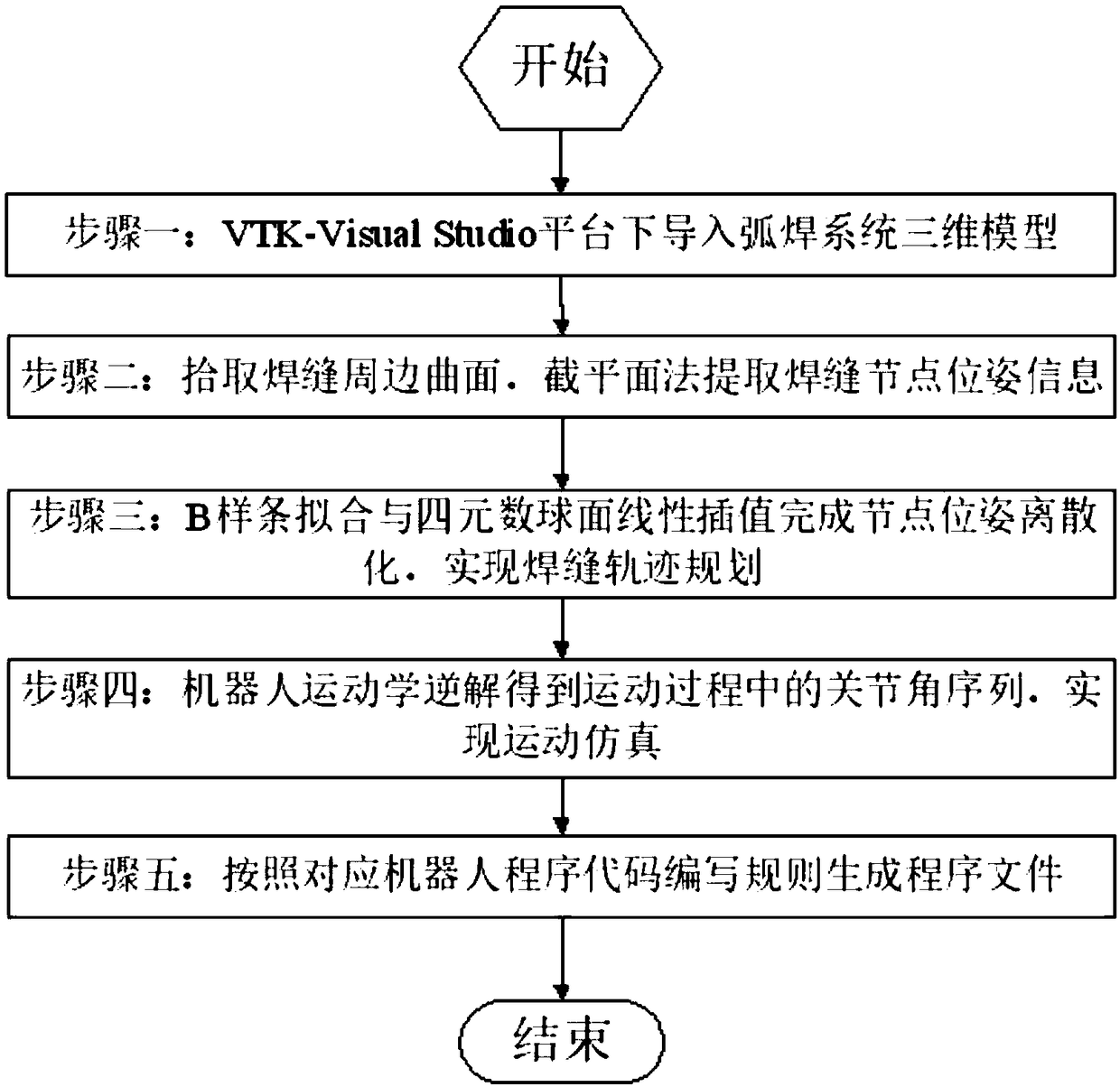

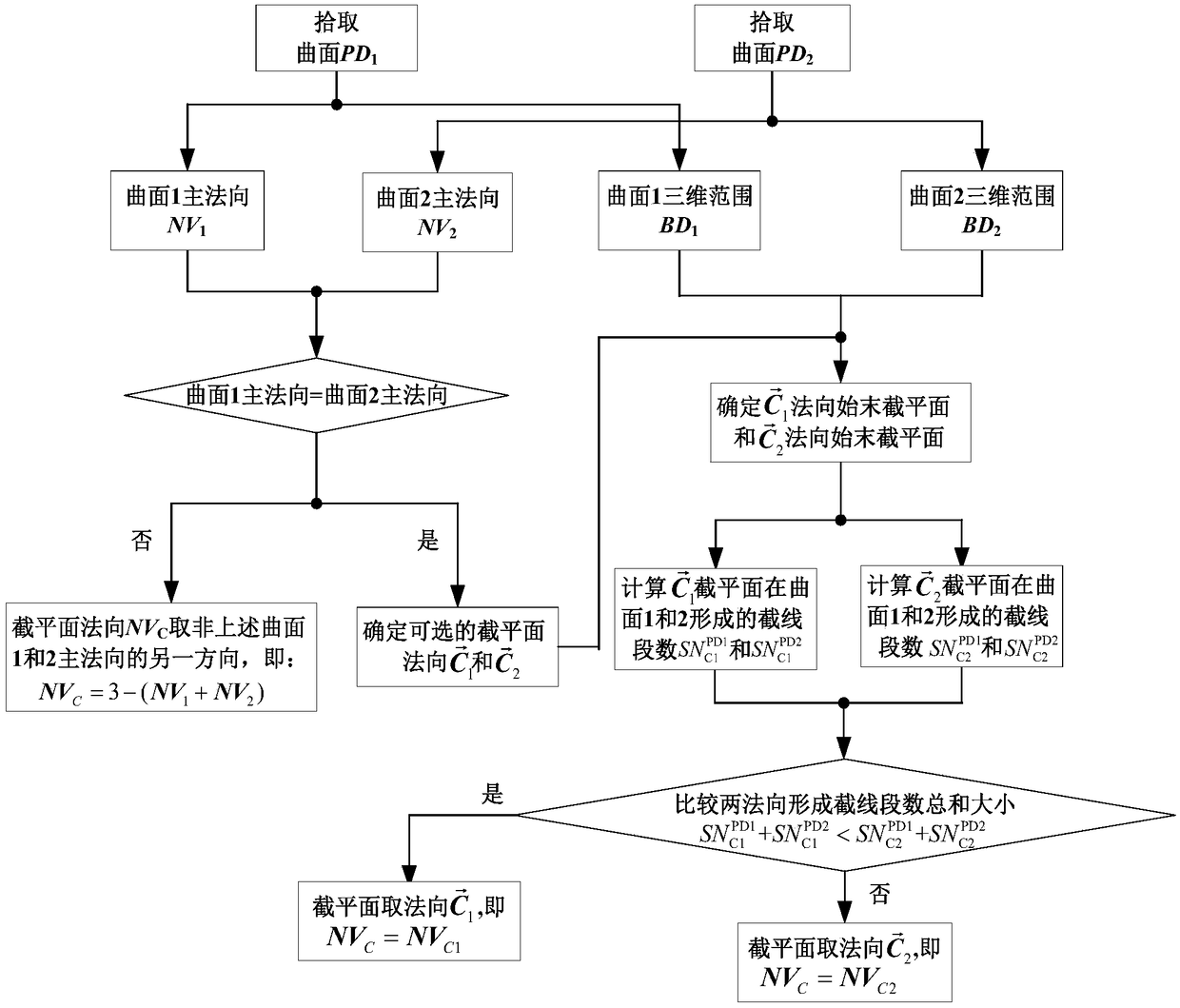

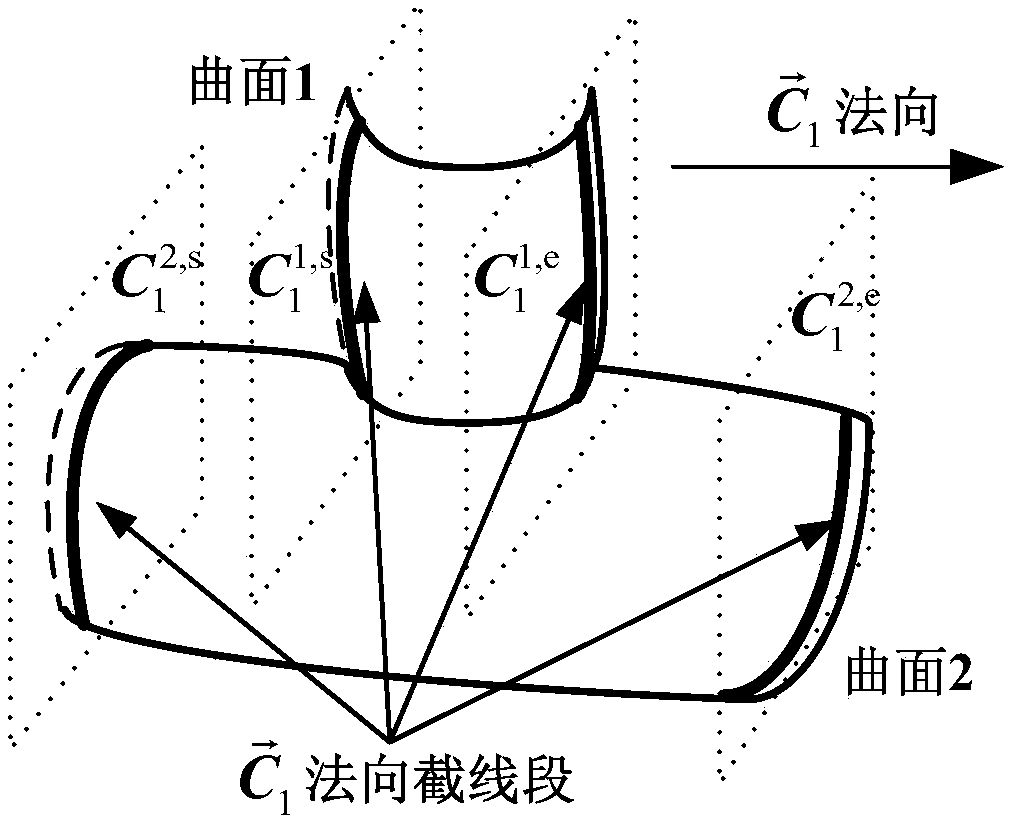

[0071] like figure 1 Shown is an off-line programming method for industrial robot space intersecting curve welding, the implementation steps are as follows:

[0072] Step 1: Import the 3D model of the arc welding system and lay it out in the offline programming environment. In order to complete the layout, the robot and the workpiece are calibrated according to the actual pose relationship. According to the calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com