An eccentric shaft and its forming process

An eccentric shaft and eccentric technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammering machinery, etc., can solve the problems of large machining allowance and high comprehensive cost, reduce machining allowance and improve longitudinal mechanical properties , to ensure the effect of the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

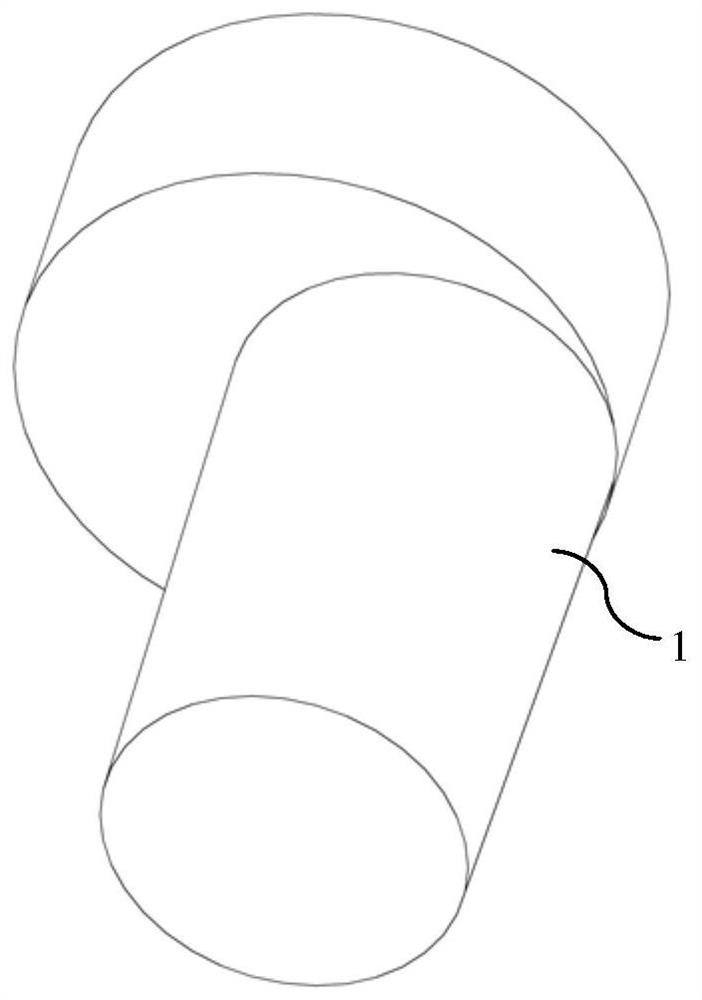

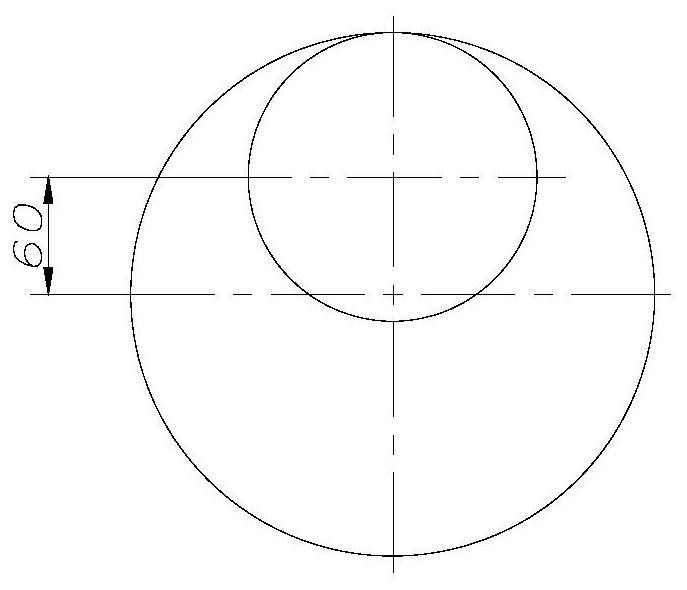

[0035] The finished eccentric shaft to be forged is as image 3 and 4 As shown, the diameter of the large outer diameter end is 300mm, the height is 140mm, the diameter of the small end of the eccentric shaft is 180mm, the height is 340mm, and the central axis distance between the large outer diameter end and the small end of the eccentric shaft is 60mm.

[0036] The forging process is as follows:

[0037] (1) Processing eccentric mold 4 (such as Figure 5 As shown), the eccentric mold 4 has a large outer diameter end cavity 41 and an eccentric shaft small end cavity 42 with the central axis staggered, and the large outer diameter end cavity 41 has a margin according to the size of the large outer diameter end of the eccentric shaft. The size of the small end cavity 42 of the eccentric shaft leaves a margin according to the size of the small end of the eccentric shaft;

[0038] Preferably, an annular step 43 is processed at the junction of the cavity 41 at the large outer d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com