Ureteral catheter structure

A ureter and catheter technology, applied in the direction of catheter, ureteroscope, application, etc., can solve the problems of easy bending or rolling of ureter, excessive movement, affecting use and detection effect, etc., and achieves good bending effect and good waterproof effect. , Detection of stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

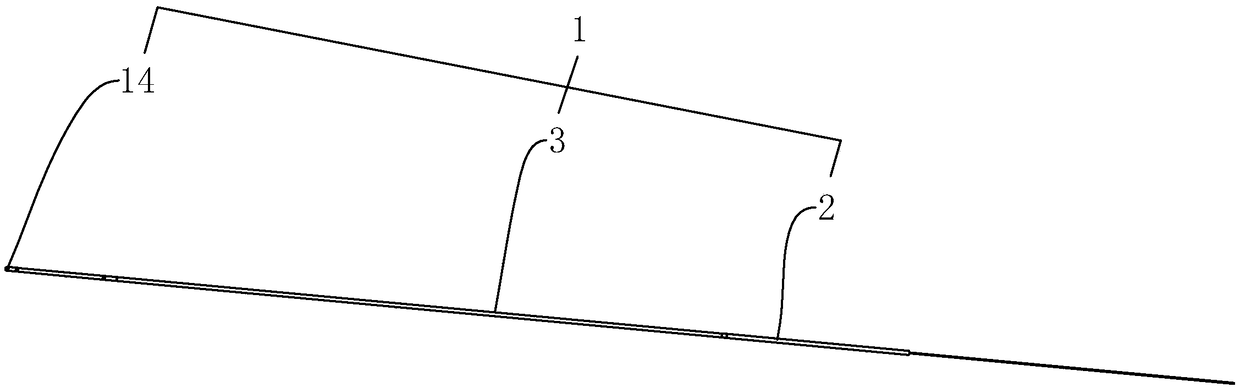

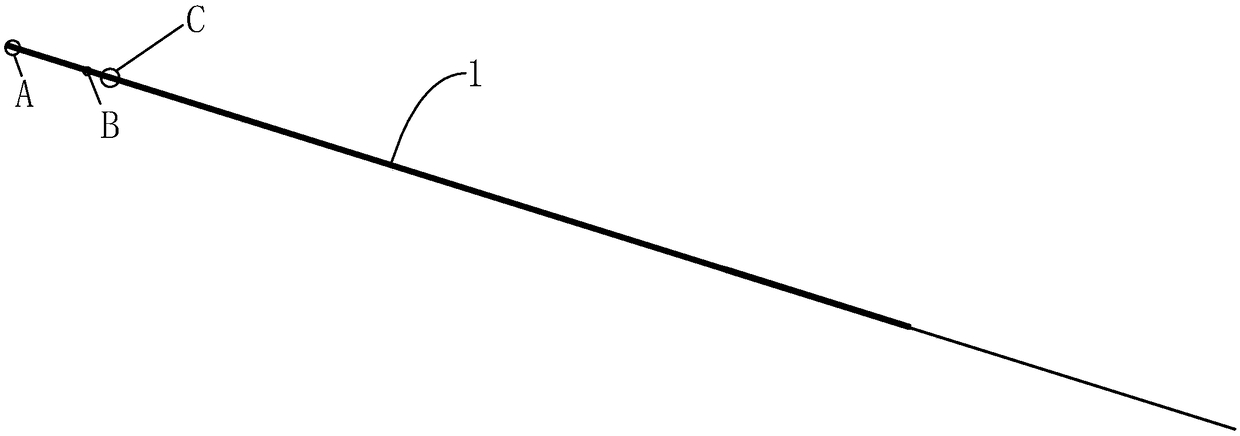

[0042] Example 1: Reference figure 1 , which is a ureteral catheter structure disclosed in the present invention, including a catheter body 1 , and the catheter body 1 includes a stepped braided tube 2 , a curved tube 3 and a plastic catheter head 14 .

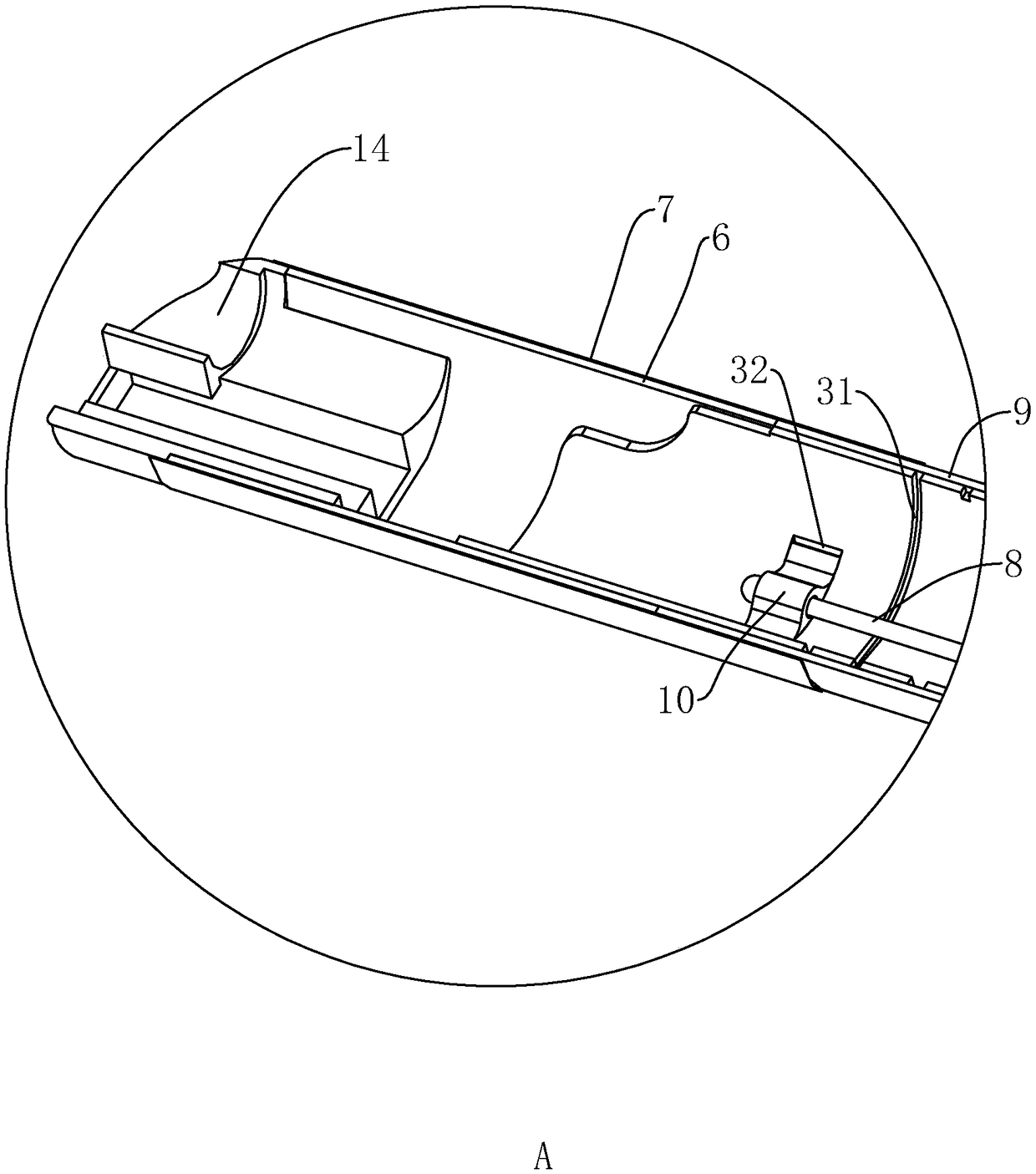

[0043] refer to figure 2 and Figure 5 , wherein the stepped braided tube 2 can be made of nickel-titanium alloy, the stepped braided tube 2 and the curved tube 3 are spliced, the joint of the stepped braided tube 2 and the curved tube 3 is covered with the first stainless steel outer tube 4, and the first stainless steel outer tube 4 The outside is covered by the first PET heat-shrinkable film 5, and the first PET heat-shrinkable film 5 can undertake each component after being heat-shrinkable and wrapped.

[0044] The step braided pipe 2 is provided with a liner body 21, the liner body 21 makes the outer wall of the step braided pipe 2 form a stepped shoulder, and the liner body 21 can be used for sliding fit of the first st...

Embodiment 2

[0047] Embodiment 2: The difference with the embodiment is that, as Figure 7 and Figure 8 , the curved pipe 3 is divided into several snake joints 33 along its length direction, and each adjacent snake joint 33 is spliced with each other but not connected. The snake joint 33 is provided with a guide convex circle 332 and a guide groove 333. The guide convex circle 332 and the guide groove 333 cooperate with each other to form relative rotation restrictions. The heat-shrinkable sleeve 9 recovers quickly from deformation. The serpentine joint 33 is formed with an inner convex ring 331 by stamping. The inner convex ring 331 can pass through the pulling wire 8 and serve as a guiding structure so that the pulling wire 8 passes through the stepped braided tube 2 at the other end.

[0048] like Figure 8 , the inner side of the step braided pipe 2 is provided with an inlay groove 22, and the inside of the inlay groove 22 is embedded with a stainless steel inner tube 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com