Fly-killing composite agent and preparation method thereof

A compound agent and fly-killing technology, applied in the field of fly trapping, can solve the problem that fly-killing agents cannot decompose malodorous gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

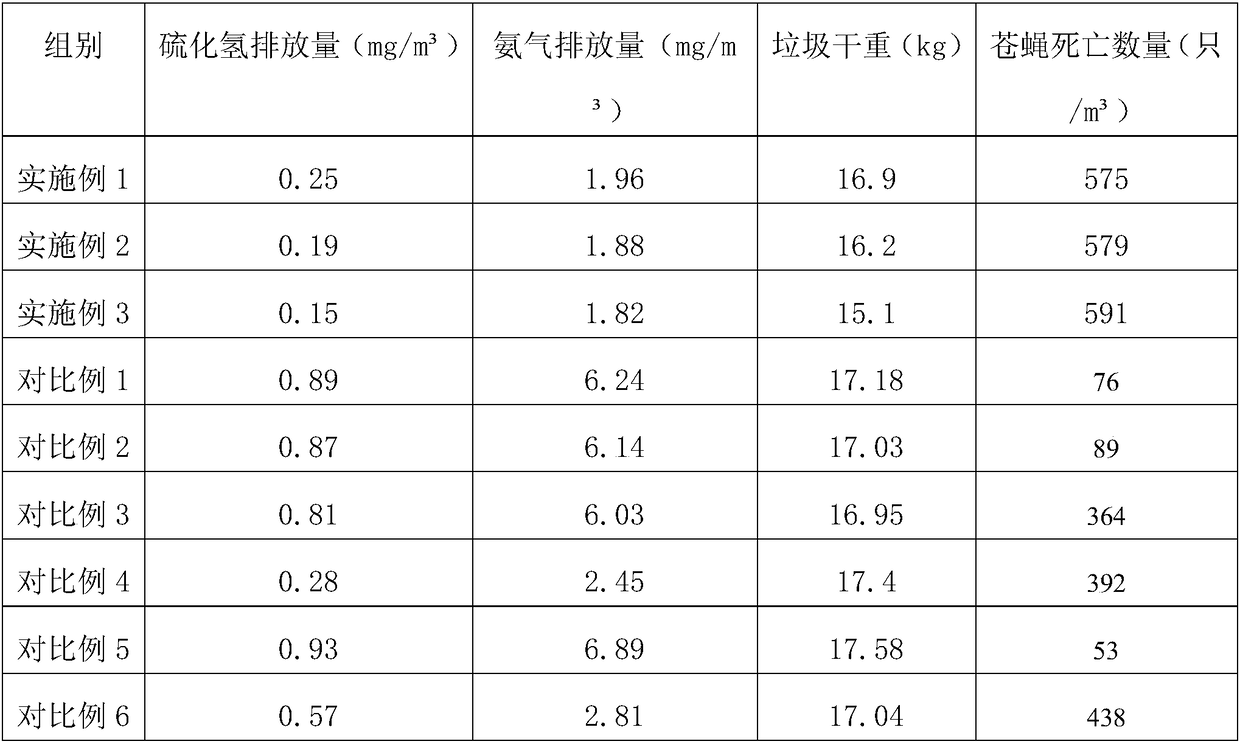

Examples

Embodiment 1

[0018] The preparation method of fly killing compound comprises the following steps:

[0019] Step 1: Squeeze 33 parts of stevia leaves and 22 parts of yacon fruit, separate stevia leaves from yacon fruit juice and slag, and obtain mixed juice and mixed slag;

[0020] Step 2: Mix 22 parts of imidacloprid, 7 parts of sodium oxamate, 13 parts of cellulose-degrading bacteria, 13 parts of COD-degrading bacteria, 9 parts of lactic acid bacteria, 9 parts of Bacillus, 19 parts of yeast, and mixed slag to obtain mixed raw materials, use The jet mill pulverizes the mixed raw materials to 20 μm to obtain a mixed material; the mixed liquid is added to the mixed material, stirred evenly, granulated, dried, and the fly-killing compound agent is obtained.

Embodiment 2

[0022] The preparation method of fly killing compound comprises the following steps:

[0023] Step 1: Squeeze 37 parts of stevia leaves and 25 parts of yacon fruit, separate stevia leaves from yacon fruit juice and slag to obtain mixed juice and mixed slag;

[0024] Step 2: Mix 25 parts of imidacloprid, 5 parts of sodium oxamate, 13 parts of cellulose-degrading bacteria, 11 parts of COD-degrading bacteria, 11 parts of lactic acid bacteria, 11 parts of Bacillus, 21 parts of yeast, and mixed slag to obtain mixed raw materials. The jet mill pulverizes the mixed raw materials to 25 μm to obtain a mixed material; the mixed liquid is added to the mixed material, stirred evenly, granulated, dried, and the fly-killing compound agent is obtained.

Embodiment 3

[0026] The preparation method of fly killing compound comprises the following steps:

[0027] Step 1: Squeeze 40 parts of stevia leaves and 28 parts of yacon fruit, separate stevia leaves from yacon fruit juice and slag, and obtain mixed juice and mixed slag;

[0028] Step 2: Mix 29 parts of imidacloprid, 9 parts of sodium oxamate, 14 parts of cellulose-degrading bacteria, 14 parts of COD-degrading bacteria, 12 parts of lactic acid bacteria, 12 parts of Bacillus, 22 parts of yeast, and mixed slag to obtain mixed raw materials, use The jet pulverizer crushes the mixed raw materials to 30 μm to obtain a mixed material; the mixed liquid is added to the mixed material, stirred evenly, granulated, and dried to obtain a fly-killing compound agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com