Molten aluminum and electrolyte level measurement system in production of electrolytic aluminum based on machine vision

A technology of electrolyte level and machine vision detection, which is applied to the level indicators of level members, camera devices, etc., can solve problems that affect test accuracy, error-prone data input, and harsh operating environments, etc., to achieve small errors and high accuracy , good repeatability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation, structure, features and effects of a machine vision-based aluminum liquid and electrolyte level measurement system in electrolytic aluminum production according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The drawings involved therein only illustrate some implementation cases of the present invention, and should not be regarded as limiting the scope. Other related information can be obtained according to the attached drawings.

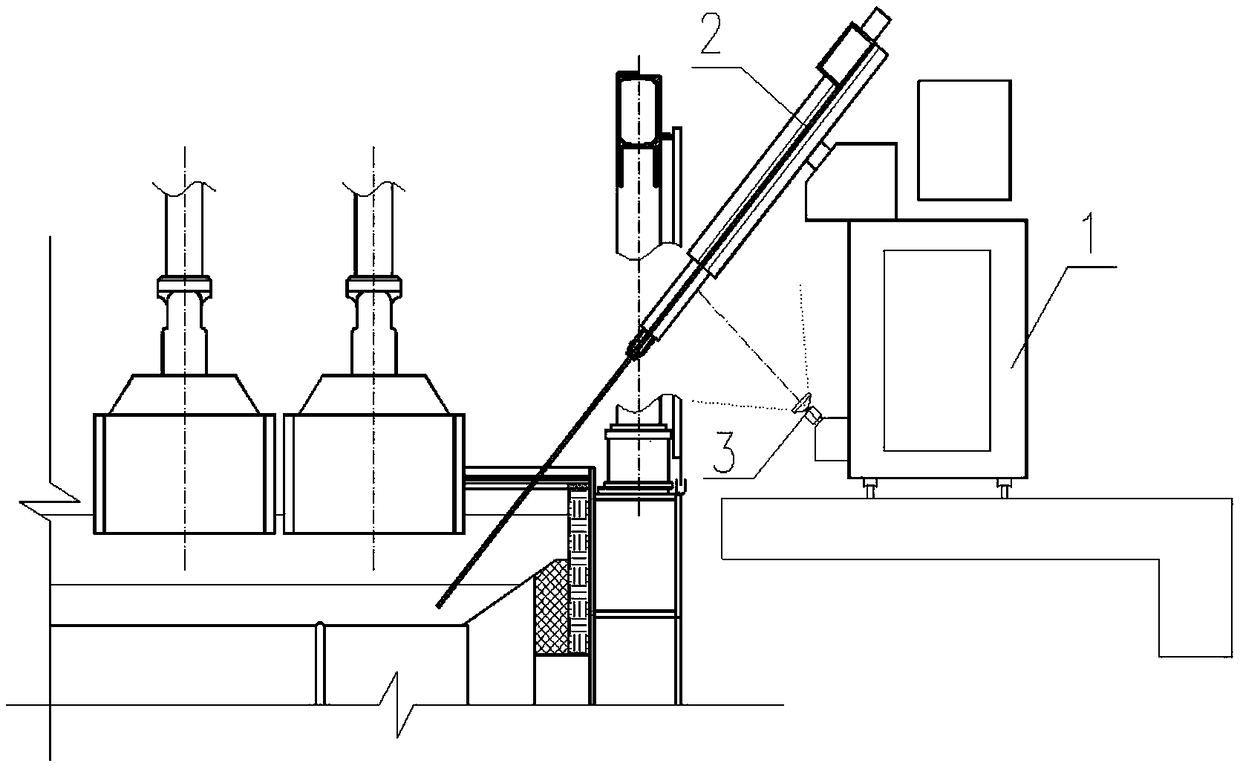

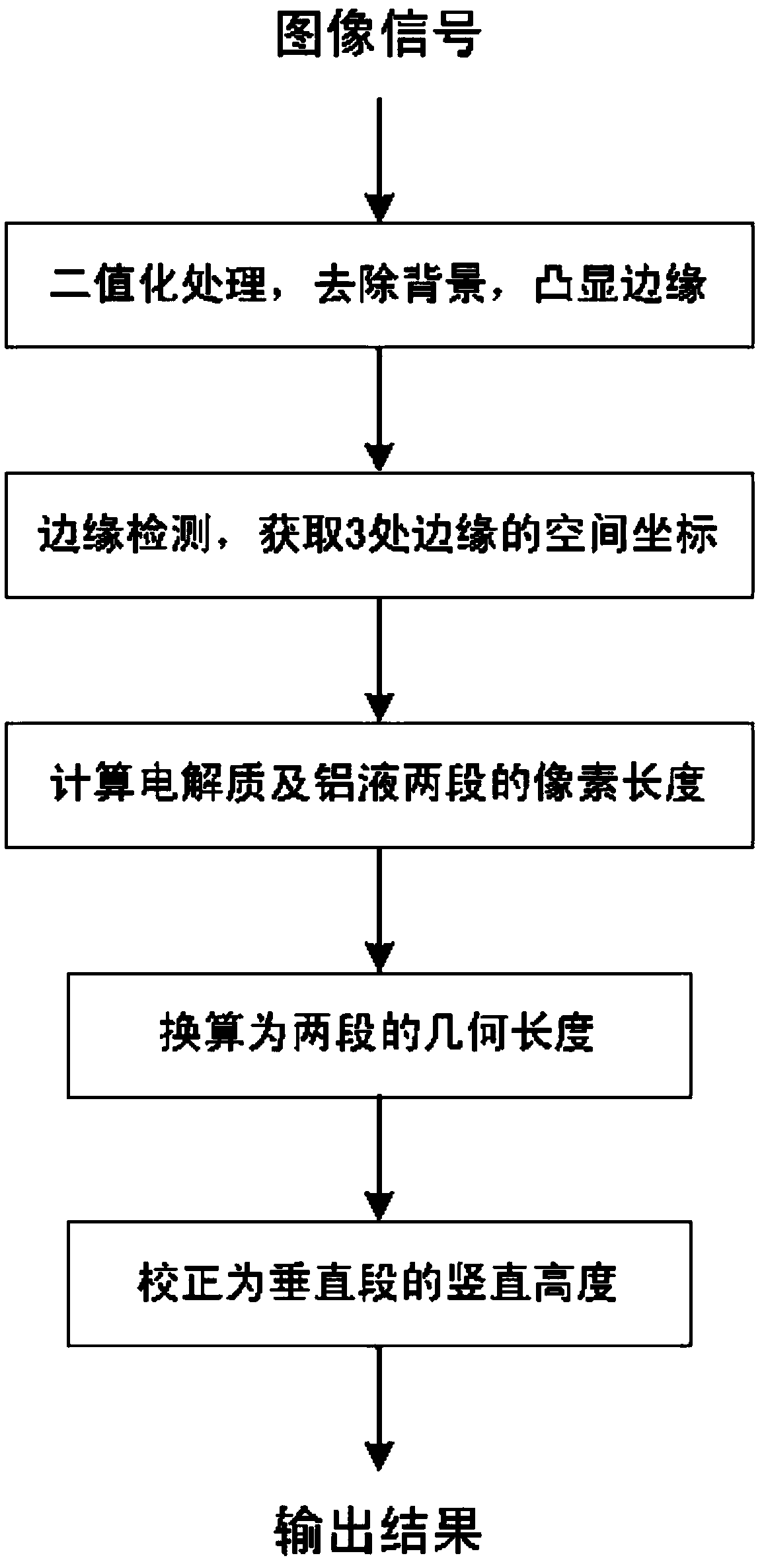

[0023] The equipment for automatically measuring the aluminum liquid and electrolyte levels in the electrolytic cell of the present invention includes the following systems: AGV inspection trolley system 1; brazing system 2 and its control system; machine vision detection system 3; The wireless transmission system in the environment can adopt the wireless transmission system used in the existing electrolytic aluminum. like figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com