High strength flame retardant environmentally friendly packing paper

A wrapping paper, high-strength technology, applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of personal and property safety loss, hidden dangers of wrapping paper safety, accelerated combustion, etc., to enhance protection function, improve load-bearing capacity and resistance Combustibility, increase the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

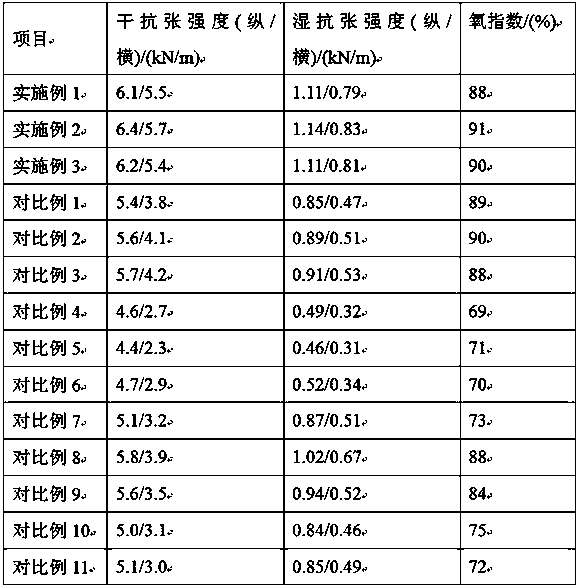

Examples

Embodiment 1

[0016] A high-strength flame-retardant and environmentally friendly wrapping paper, made of the following raw materials in parts by weight: cotton straw 45, corn straw 36, wheat straw 21, glass fiber 9, nano silicon dioxide 5, nano zinc oxide 4, polylactic acid 0.21, Compound enzyme 0.02.

[0017] The compound enzyme is composed of the following raw materials in parts by weight: hemicellulase 18, ligninase 15, lipase 10, amylase 2.

[0018] A preparation method of high-strength flame-retardant environment-friendly wrapping paper, comprising the following steps:

[0019] (1) Crush cotton stalks, corn stalks and wheat stalks to 5~8mm, add them into water, the ratio of solid to liquid is 1:2~3, mix evenly, add compound enzymes, keep warm at 43°C for 2 hours to obtain enzymatic hydrolyzed material ;

[0020] (2) Add white rot fungus to the enzymolysis material, the addition amount is 3% of the weight of the enzymolysis material, mix well, and ferment at 31°C for 10 days to obtai...

Embodiment 2

[0026] A high-strength flame-retardant and environmentally friendly wrapping paper, made of the following raw materials in parts by weight: cotton straw 46, corn straw 37, wheat straw 22, glass fiber 10, nano silicon dioxide 6, nano zinc oxide 5, polylactic acid 0.22, Compound enzyme 0.025.

[0027] The compound enzyme is composed of the following raw materials in parts by weight: hemicellulase 19, ligninase 16, lipase 11 and amylase 3.

[0028] A preparation method of high-strength flame-retardant environment-friendly wrapping paper, comprising the following steps:

[0029] (1) Crush cotton stalks, corn stalks and wheat stalks to 5~8mm, add them into water, the ratio of material to liquid is 1:2~3, mix evenly, add complex enzymes, keep warm at 44°C for 2.5h to obtain enzymolysis material;

[0030] (2) Add white rot fungus to the enzymolysis material, the addition amount is 4% of the weight of the enzymolysis material, mix well, and ferment at 32°C for 11 days to obtain the ...

Embodiment 3

[0036] A high-strength flame-retardant and environmentally friendly wrapping paper, made of the following raw materials in parts by weight: cotton straw 47, corn straw 38, wheat straw 23, glass fiber 11, nano-silica 7, nano-zinc oxide 6, polylactic acid 0.23, Compound enzyme 0.03.

[0037] The compound enzyme is composed of the following raw materials in parts by weight: hemicellulase 20, ligninase 17, lipase 12, amylase 4.

[0038] A preparation method of high-strength flame-retardant environment-friendly wrapping paper, comprising the following steps:

[0039] (1) Crush cotton stalks, corn stalks and wheat stalks to 5-8mm, add them into water, the ratio of material to liquid is 1:3, mix evenly, add compound enzyme, keep warm at 45°C for 3 hours to obtain enzymatic hydrolyzed material;

[0040] (2) Add white rot fungus to the enzymolysis material, the addition amount is 5% of the weight of the enzymolysis material, mix evenly, and ferment at 33°C for 12 days to obtain the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com