A novel needle-free electrospinning device and spinning method thereof

An electrospinning and spinning technology, which is applied in the field of new needle-free electrospinning devices, can solve problems affecting the production stability, discharge, and safety hazards of nanofibers, and achieve fine fiber diameter, long range, and high uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

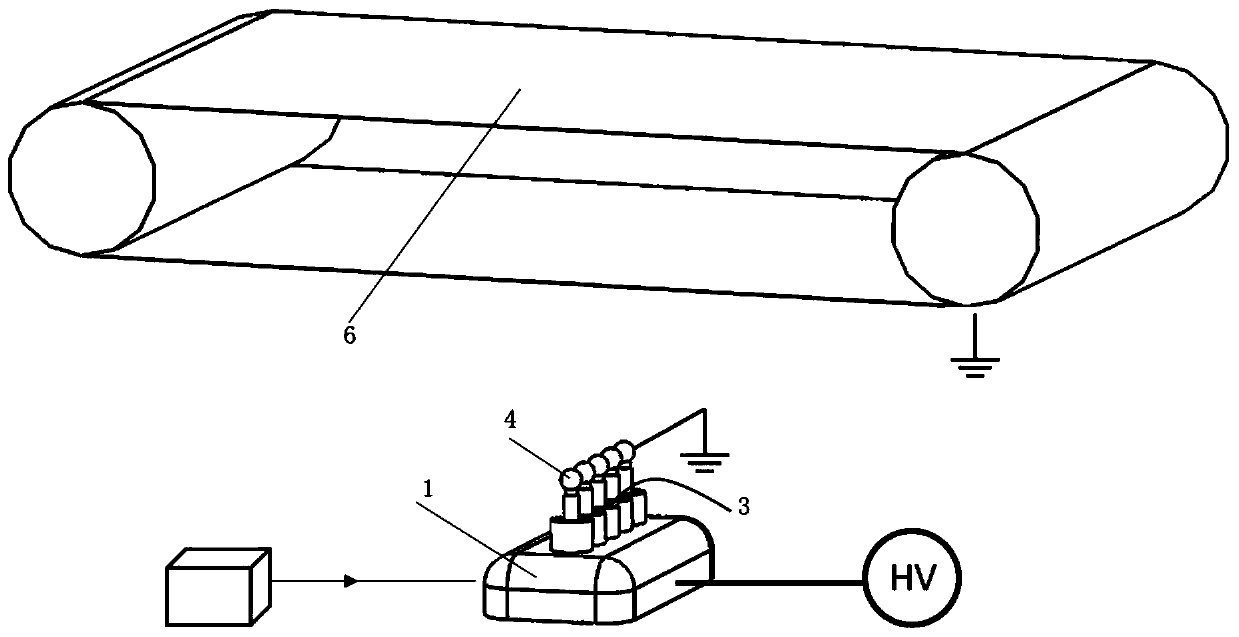

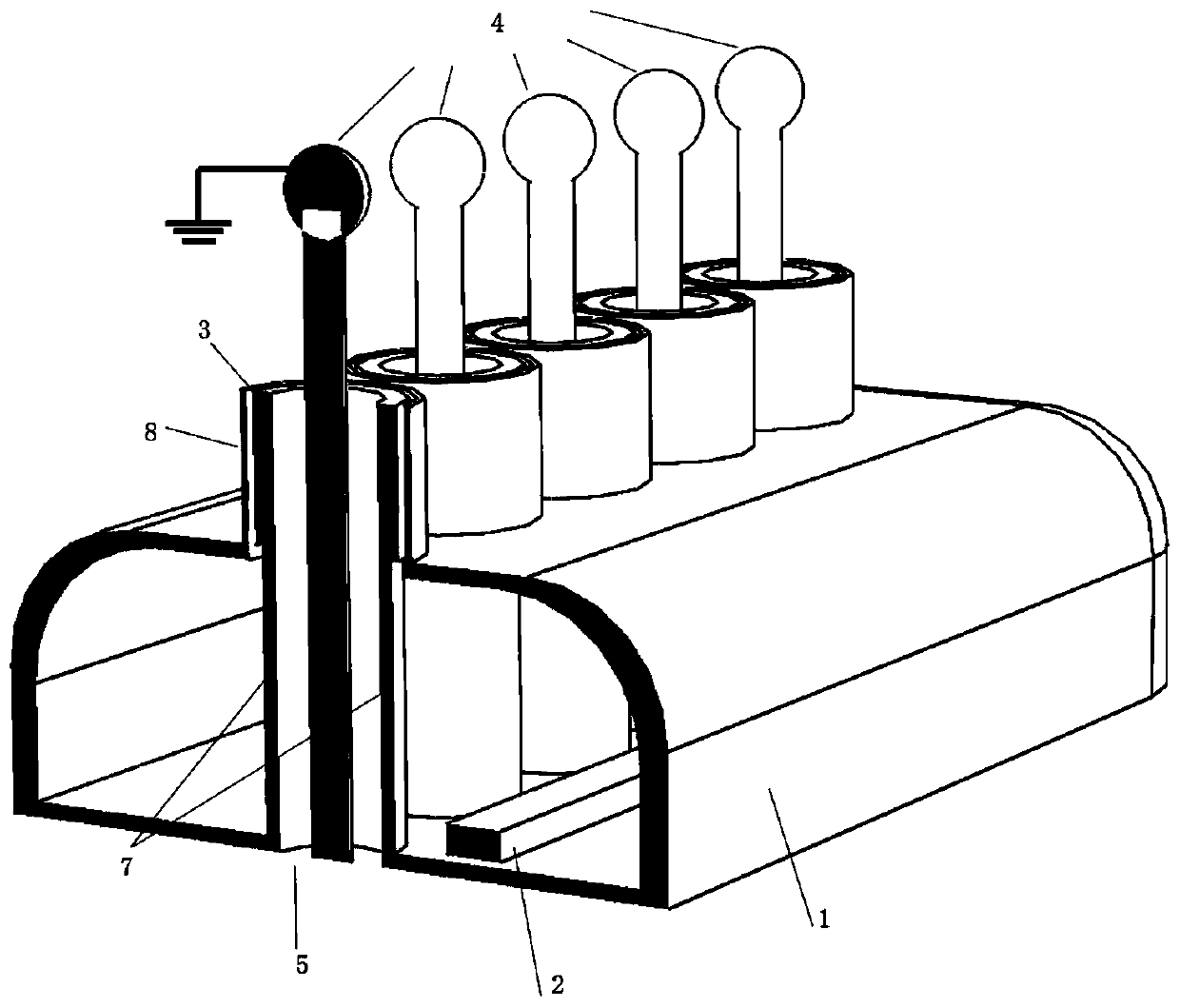

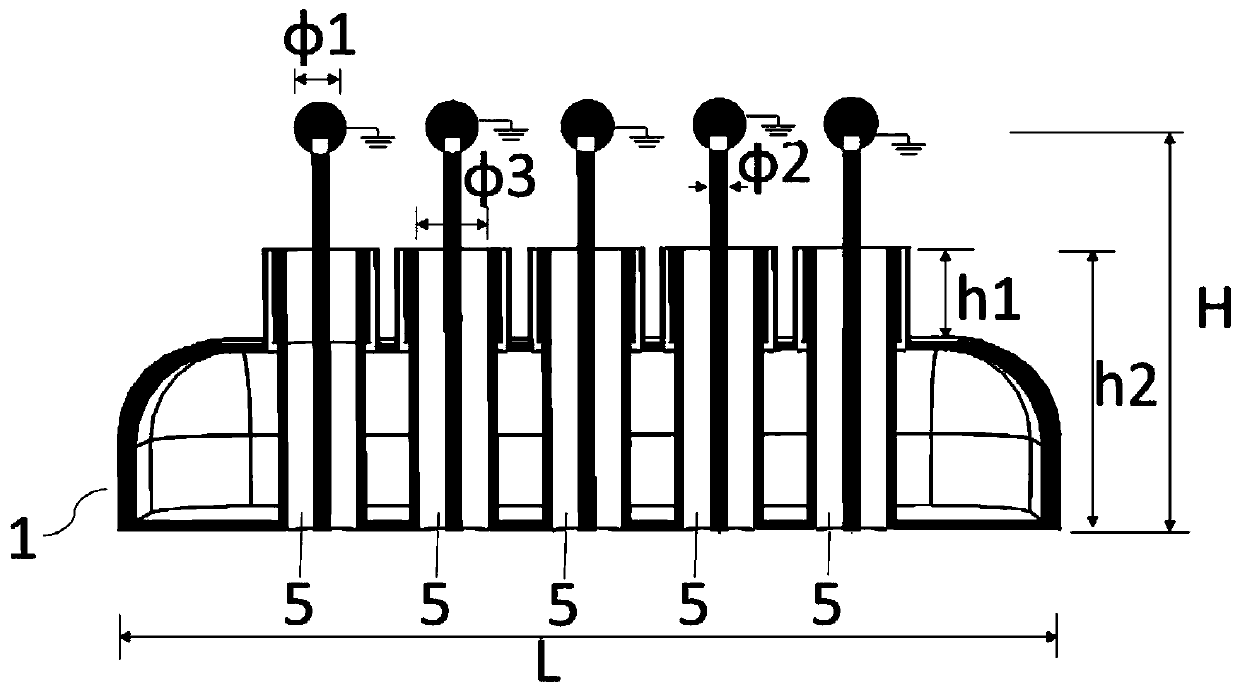

[0130] The electrospinning device used in Example 1 of the present invention is as figure 1 shown. The electrostatic spinning device includes: a spinning solution chamber, a spinning slit, an air flow channel, an intermediate electrode, and a collecting electrode plate. The collecting electrode plate is driven to rotate by a driving device, for example, a motor drives the collecting electrode plate to rotate at a speed of 40 rpm. The ground electrode of the intermediate electrode voltage is connected to induce the production of nanofibers; the collecting electrode plate is connected to the ground electrode and used to receive the produced nanofibers. The distance between the spinning slit and the collecting electrode plate is 200 mm, the distance between the spinning slit and the intermediate electrode is 100 mm, the diameter of the gas flow channel is 20 mm, and the flow rate of the gas in the gas flow channel is 20 m / s.

[0131] figure 2 and 3 shown as figure 1 A more ...

Embodiment 2

[0137] The spinning device reference used in this embodiment figure 1 , the intermediate electrode shown as Figure 10 Shown, a cylindrical interposer. The diameter φ4 of the intermediate electrode was 15 mm, and the height h3 of the intermediate electrode was 10 mm. The distance between the intermediate electrode and the slit is 50 mm. The specific shape of the spinning slit is rhombus, such as Figure 14 As shown, the diagonal length l1 of the rhombus is 80mm, the distance between the centers of the rhombus is 100mm, and the internal angles of the rhombus are all 90°. The distance between the spinning slot and the fiber collecting electrode was 200 mm. The diameter of the gas flow channel is 25mm, and the flow velocity of the gas is 25m / s. The slit is made of polypropylene plastic. All the other test parameters are the same as in Example 1.

[0138] For experimental purposes, the nanofibers were formed using a polymer solution produced by Sigma-Aldrich with a viscosit...

Embodiment 3

[0141] The spinning device reference used in this embodiment figure 1 , the slit spinneret shown in the figure is as Figure 15 As shown, it is a rectangular closed linear spinning head. The length L3 of the rectangle is 50 mm, the width l3 of the rectangle is 50 mm, and the distance d4 between the centers of each rectangle is 50 mm. The width d5 of the slit is 2 mm. The distance between the spinning slot and the fiber collecting electrode was 180 mm. The intermediate electrode is a cone, such as Figure 11 As shown, the diameter φ5 of the bottom surface of the cone is 20 mm, the height h4 is 10 mm, and the distance between the intermediate electrode and the slit is 60 mm. The flow velocity of the gas in the gas flow channel is 20m / s. The material of the slit is aluminum. All the other test parameters are the same as in Example 1.

[0142] For experimental purposes, the nanofibers were formed using a polymer solution produced by Sigma-Aldrich with a viscosity of 1100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com