High-speed steel hob ion nitriding method and tool

A technology of ion nitriding and high-speed steel, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low precision, high temperature of the tip of the tool, and difficulty in heating up, so as to prevent the hardness of the tip of the tool from decreasing , avoid tip discharge, and avoid the effect of increasing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

[0028] A high-speed steel hob plasma nitriding method and tooling.

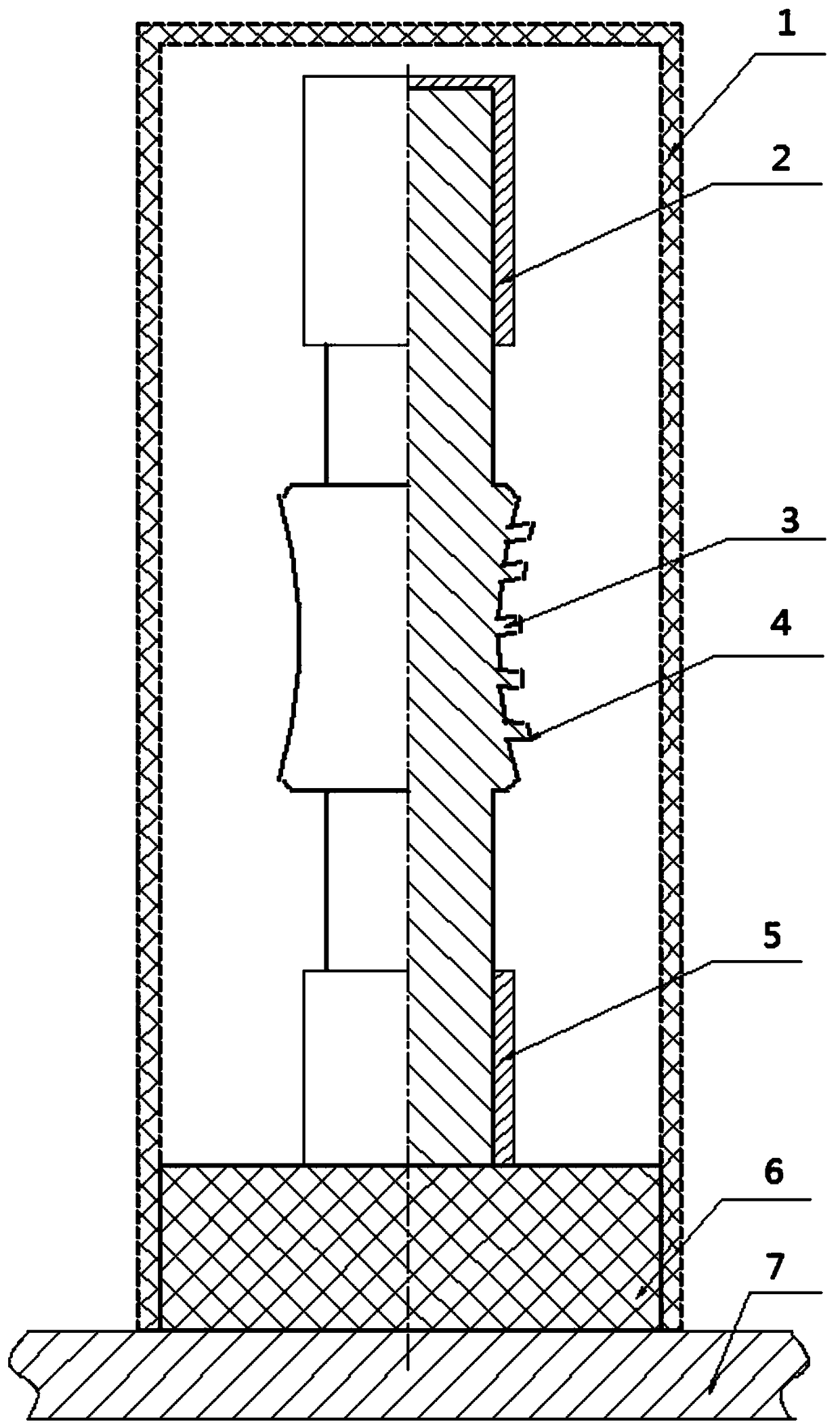

[0029] A high-speed steel hob ion nitriding tooling, including an insulating mica base 6, a glow screen 1, an upper anti-nitridation cover 2 and a lower anti-nitridation cover 5;

[0030] The glow screen is a steel mesh made of Q195 steel wire and is in the shape of a cover with a lower opening; when in use, the upper anti-nitridation cover 2 and the lower anti-nitridation cover 5 are respectively detachably placed on the high-speed steel hob 3 The upper and lower ends of the upper and lower ends are in the shape of caps and are made of Q195 material, which can avoid nitriding of the handles at both ends of the high-speed steel hob 3 and ensure the accuracy requirements of the handles at both ends of the high-speed steel hob 3;

[0031] The insulating mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com