A high-flavone tartary buckwheat beverage vinegar and its preparation method

A technology of high flavonoids and tartary buckwheat, applied in the field of food processing, can solve the problems of increasing the filtration volume and loss of tartary buckwheat vinegar mash, and the volume of supernatant is small, and achieve the effect of soft sour taste, yellow-green color, and anti-aging immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

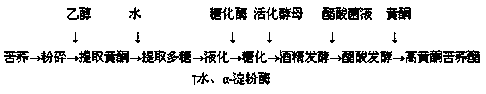

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of tartary buckwheat drink vinegar with high flavonoids, comprising the following steps:

[0037] (1) Extraction of flavonoids:

[0038] a. Select 30Kg tartary buckwheat to germinate, dry the sprouts, crush them through a 40-mesh sieve, add 60% ethanol at a solid-liquid ratio of 1:35 to the sprout powder, and extract them ultrasonically for 50 minutes at 62°C to obtain Extract the flavonoids of buckwheat bud powder, and dry it with low-temperature blast after rotary evaporation to obtain the flavonoids of buckwheat buds, which will be used for later use;

[0039] b. After drying 100Kg tartary buckwheat, crush it through a 40-mesh sieve, add ethanol with a solid-liquid ratio of 1:50 and a concentration of 75% in the tartary buckwheat powder, and conduct ultrasonic-assisted extraction for 34 minutes at a temperature of 62°C to obtain buckwheat flour and The flavonoid extract was dried by low-temperature blowing after rotary evaporation to obtain tart...

Embodiment 2

[0048] A preparation method of tartary buckwheat drink vinegar with high flavonoids, comprising the following steps:

[0049] (1) Extraction of flavonoids:

[0050] a. Select 26Kg tartary buckwheat to germinate, dry the sprouts, crush them through a 60-mesh sieve, add 60% ethanol at a solid-liquid ratio of 1:35 to the sprout powder, and extract them ultrasonically for 54 minutes at 60°C to obtain Extract the flavonoids of buckwheat bud powder, and dry it with low-temperature blast after rotary evaporation to obtain the flavonoids of buckwheat buds, which will be used for later use;

[0051] b. After drying 80Kg tartary buckwheat, crush it through a 40-mesh sieve, add ethanol with a solid-to-liquid ratio of 1:50 and a concentration of 75% in the tartary buckwheat powder, and conduct ultrasonic-assisted extraction for 33 minutes at a temperature of 63°C to obtain buckwheat flour and The flavonoid extract was dried by low-temperature blowing after rotary evaporation to obtain ta...

Embodiment 3

[0060] (1) Extraction of flavonoids:

[0061] a. Select 20Kg tartary buckwheat to germinate, dry the sprouts, crush them through an 80-mesh sieve, add 60% ethanol at a solid-liquid ratio of 1:35 to the sprout powder, and extract them ultrasonically for 60 minutes at 58°C to obtain Extract the flavonoids of buckwheat bud powder, and dry it with low-temperature blast after rotary evaporation to obtain the flavonoids of buckwheat buds, which will be used for later use;

[0062] b. After drying 60Kg tartary buckwheat, crush it through a 40-mesh sieve, add ethanol with a solid-liquid ratio of 1:50 and a concentration of 75% in the tartary buckwheat powder, and conduct ultrasonic-assisted extraction for 32 minutes at a temperature of 64°C to obtain buckwheat flour and The flavonoid extract was dried by low-temperature blowing after rotary evaporation to obtain tartary buckwheat flavonoids, which was set aside;

[0063] (2) Extraction of polysaccharides: add water to the buckwheat f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com