Method for improving compatibility of stilbene-based biphenyl whitening agent and pp (polypropylene) plastic

A technology of stilbene and biphenyl, applied in the field of plastics, can solve the problems of poor compatibility, plastic whiteness and thermal stability effects, etc., to improve compatibility, enhance plastic whitening effect, and enhance yellowing point effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for improving the compatibility of distyryl biphenyls whitening agent and PP plastics, comprising the following steps:

[0055] (1) Preparation of 4,4'-distyryl biphenyl (a):

[0056]

[0057] Add 10mmol (2.512g) of 4,4'-dichloromethylbiphenyl and 20mmol (3.324g) of triethyl phosphite into a 250ml three-necked flask, reflux and stir at 155°C for 5h, and cool the reaction solution to room temperature. The yellow intermediate 4,4'-biphenylene-bis-methylphosphonic acid diethyl ester is obtained. Then use this intermediate, 20mmol benzaldehyde, and 30% methanol solution of sodium methoxide in 15ml of DMF at 55°C for 3h under reflux and stir to obtain a yellow-green crude product solution, cool to room temperature, filter with suction, and collect the solid on the filter paper with Boil 50ml of distilled water for 5 minutes, then suction filter while hot, and rinse with hot water and methanol successively. The filter cake obtained above was recrystallized with ...

Embodiment 2

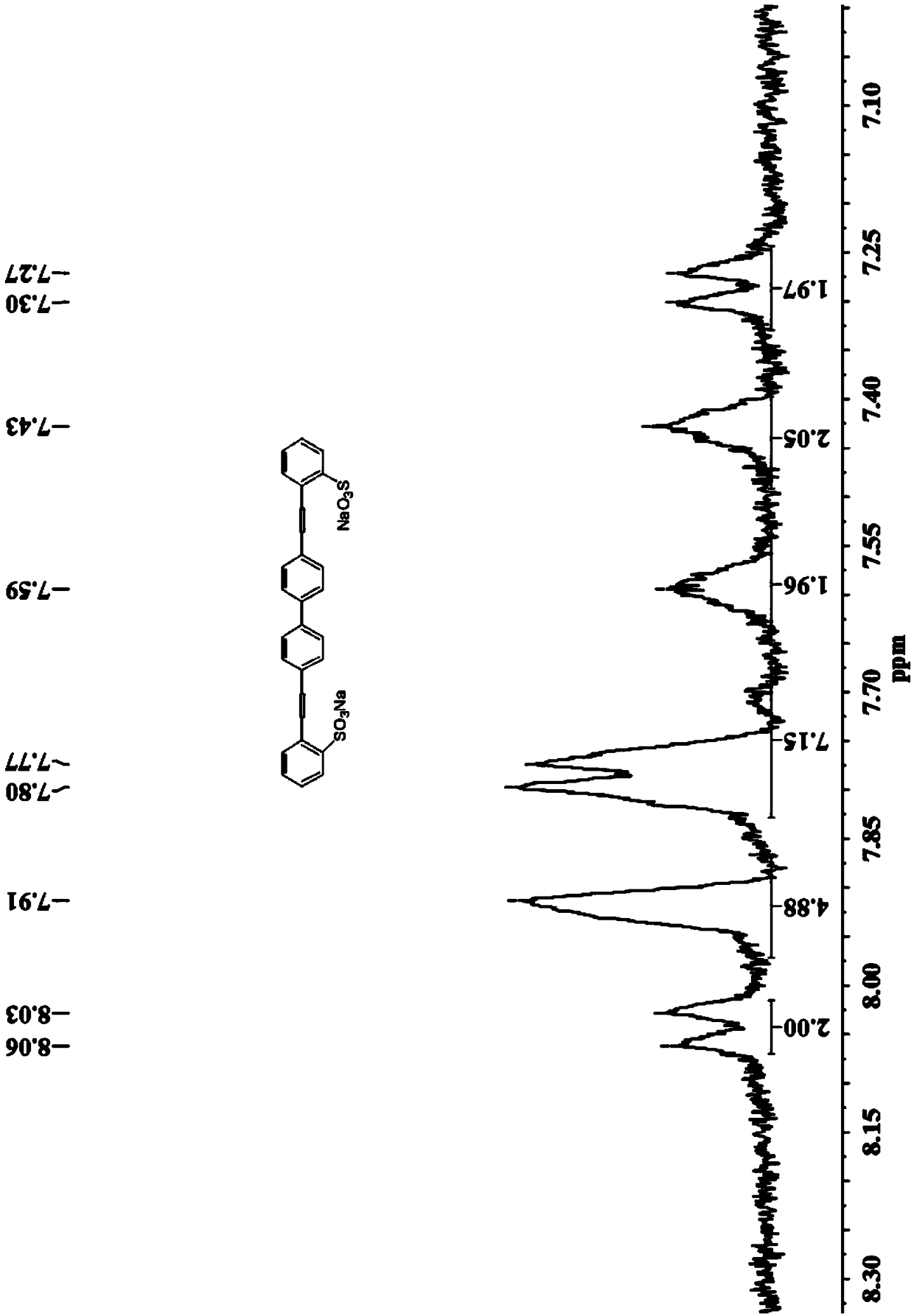

[0064] (1) Preparation of 4,4'-distyryl biphenyl-2,2'-sodium disulfonate (b):

[0065]

[0066] In a 250ml three-necked flask, add 1.2814g (5mmol) 98% biphenyl benzyl dichloride, heat to 160°C to melt, then add 1.8651g (11mmol) 98% triethyl phosphite dropwise under stirring, After reacting for 5 hours, the intermediate was obtained. Triethyl phosphite was removed and cooled to 50°C for use. Under nitrogen protection conditions, add a mixture of 2.2708g (10mmol) 90% sodium 2-formylbenzenesulfonate and 10ml dimethyl sulfoxide while stirring in the intermediate synthesized above, and then slowly add the newly prepared 5ml of sodium methoxide-methanol solution. Keep stirring, after reacting at 50°C for 3 hours, add 21ml of acetone, and let stand for 3-5 hours. Suction filtration under reduced pressure to obtain a light yellow solid, which was washed with CH 3 CH 2 OH and H 2 O mixed solvent (CH 3 CH 2 OH:H 2 O=1:1) recrystallized three times and dried to obtain the prod...

Embodiment 3

[0075] (1) Preparation of 4,4'-distyryl biphenyl-2,2',4,4'-sodium tetrasulfonate (c):

[0076]

[0077] In a 250ml three-necked flask, add 1.2814g (5mmol) 98% biphenyl benzyl dichloride, heat to 160°C to melt, then add 1.8651g (11mmol) 98% triethyl phosphite dropwise under stirring, After reacting for 5 hours, the intermediate was obtained. Triethyl phosphite was removed and cooled to 50°C for use. Under the condition of nitrogen protection, a mixture of 3.1472g (10mmol) 98% benzaldehyde-2,4-sodium disulfonate and 10ml dimethyl sulfoxide was added to the intermediate synthesized above while stirring, and then slowly added dropwise Freshly prepared 5ml of sodium methoxide-methanol solution. Keep stirring, after reacting at 50°C for 3 hours, add 21ml of acetone, and let stand for 3-5 hours. Suction filtration under reduced pressure yielded a pale yellow solid, which was recrystallized three times with a mixed solvent of ethanol and water, and dried to obtain the product. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com