Preparation method of glycine

A technology for glycine and preparation steps, applied in the field of compound preparation, can solve the problems of large centrifugal separation processing capacity, difficult methanol mother liquor treatment, and high production cost, achieve low production cost, overcome organic solvent and energy consumption, and reduce recovery costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of glycine, the steps of the first round of preparation are as follows:

[0031] A. Replacement reaction: Add chloroacetic acid into the reaction vessel, then add the alcohol solution of iodide, and stir evenly. The iodide is any one or more of ammonium iodide, sodium iodide, and potassium iodide. It is any one or a mixture of methanol, ethanol or propanol, the mass ratio of chloroacetic acid and iodide reaction is 1:0.5~5, and the mass ratio of iodide in the iodide alcohol solution is 10~50 %. Heat the reaction solution to a temperature of 30-65°C to carry out the displacement reaction, and keep stirring. The preferred temperature range is 55-65°C, and the reaction time is 30-180 minutes, preferably 90-150 minutes. After the reaction, stop heating and cool After reaching 20-35°C, solid-liquid separation is carried out by centrifugation or filtration. The obtained solid is chloride, which can be sold outside after drying. The liquid is an a...

Embodiment 1~4

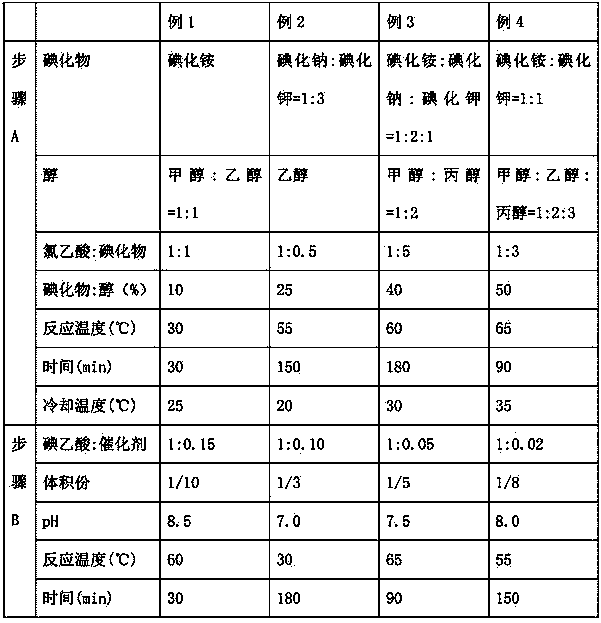

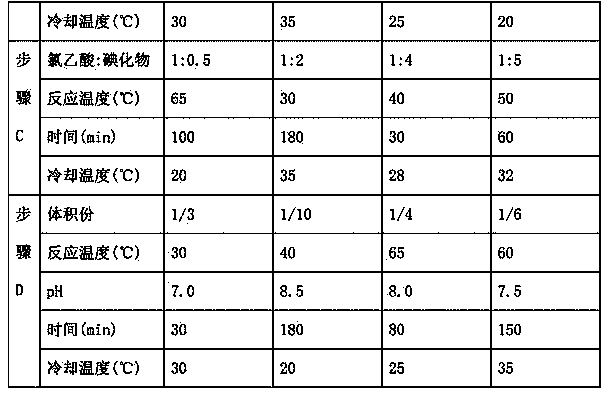

[0038] Examples 1-4 have the same production process steps as the above-mentioned specific examples, and the different process parameters or selected different types of compounds are shown in Table 1 below. Among them, "iodide" is the type of iodide, the ratio value in the table is the mass ratio when several iodides are mixed, "alcohol" is the type of alcohol, and the ratio value in the table is the mass ratio when several alcohols are mixed .

[0039] Table 1

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com