Moving device for automatic loading compartment centralized assembling and double-compartment equipment

A mobile device and box technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of manual push, etc., and achieve the effects of reducing moving resistance, improving stability, and improving moving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

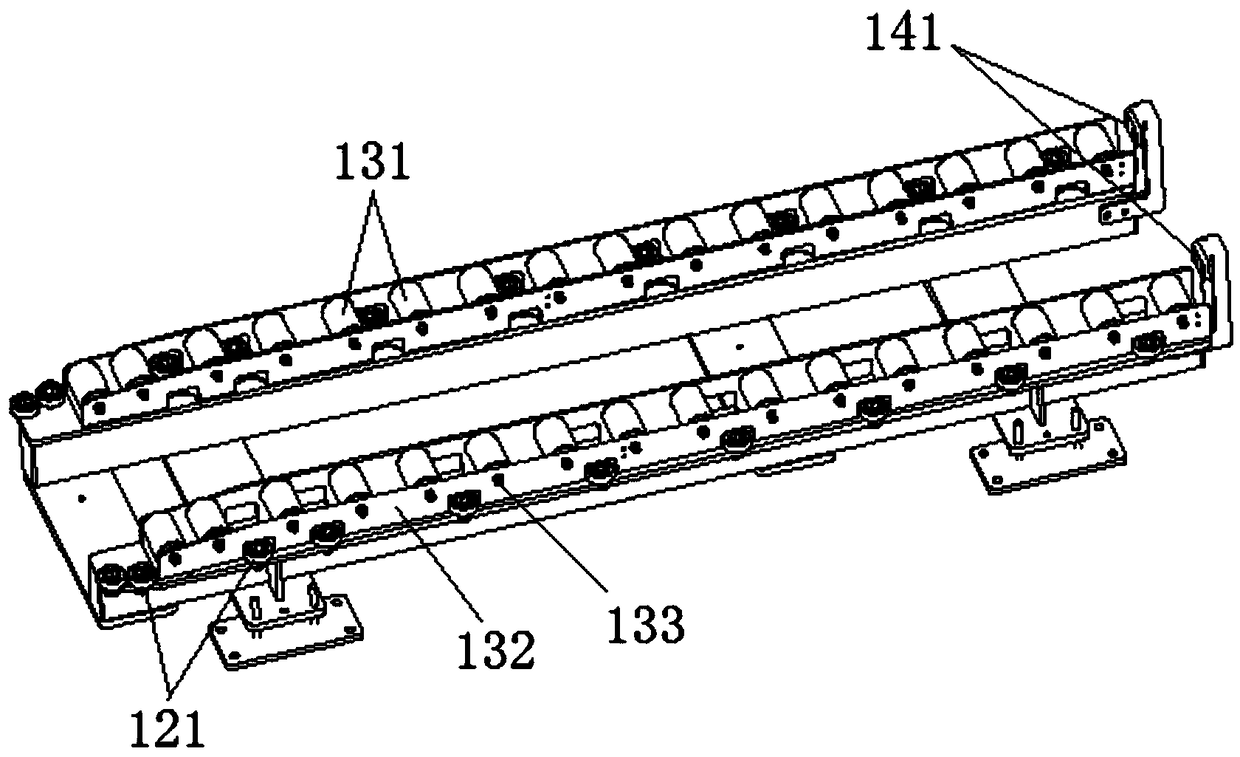

[0077] This embodiment provides a mobile device for the automatic collection and distribution of the logistics cargo compartment 5, such as figure 1 As shown, it includes a guiding support mechanism 1, a driving mechanism 2 and an articulation mechanism 3. The articulation mechanism 3 is connected to the driving end of the driving mechanism 2, and the driving mechanism 2 is arranged along the guiding and supporting mechanism 1. During work, the articulation mechanism 3 Carry out clamping connection with the loading box body 5 through the action, the driving mechanism 2 drives the hitch mechanism 3 to move along the guide support mechanism 1, and the bottom of the loading box body 5 contacts the guide support mechanism 1, so that the loading box body 5 moves along the guide support mechanism 1. Guide the path set by the support mechanism 1 to move; after the loading compartment 5 reaches the preset position, the hooking mechanism 3 releases the clamping connection with the loadi...

Embodiment 2

[0093] This embodiment provides a two-compartment equipment, such as Figure 7 , Figure 8As shown, it includes the mobile device described in Embodiment 1, and also includes a cargo compartment 5 .

[0094] There is at least one loading compartment 5, erected above the mobile device, and the bottom is provided with a bottom plate 51 for carrying the material trolley 4 and cooperating with the mobile device, and the bottom surface of the bottom plate 51 is provided with a vertical downward The car body guide plate 52 is used to cooperate with the guide support mechanism 1 to guide the loading box body 5; the bottom of the loading box body 5 is also provided with a The hooking groove 53 that the above-mentioned hooking mechanism 3 cooperates.

[0095] Instructions

[0096] Before the moving device is moved to the bottom of the loading compartment 5, the hitch mechanism 3 is first deformed so that the hitch claws 31 shrink downward;

[0097] After moving the mobile device to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com