Environment-friendly dust removing, polishing and grinding machine

A polishing and environmental protection technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as poor working conditions, air pollution, and poor working environment, and improve work efficiency. Environmental quality, improve the degree of automation, solve the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

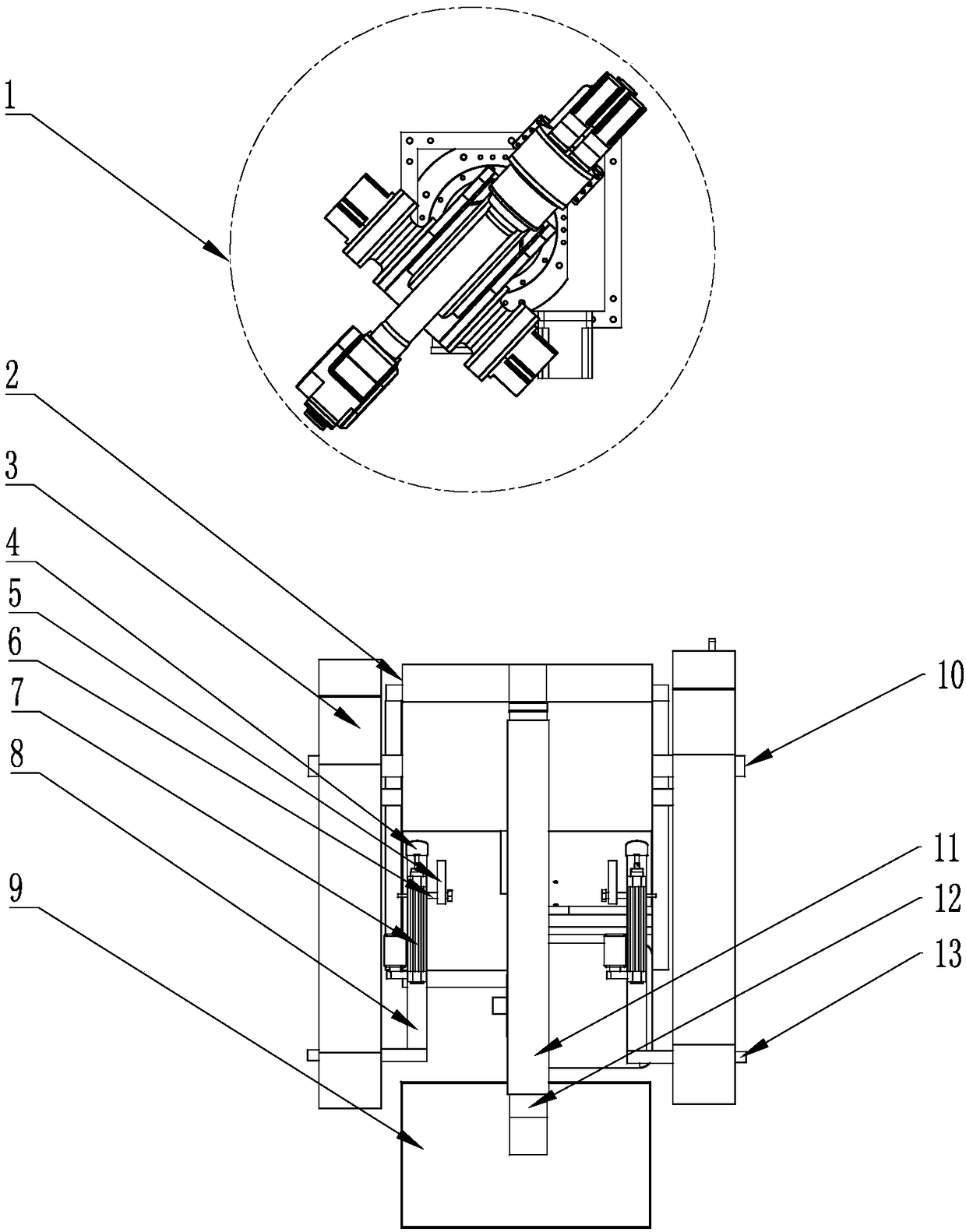

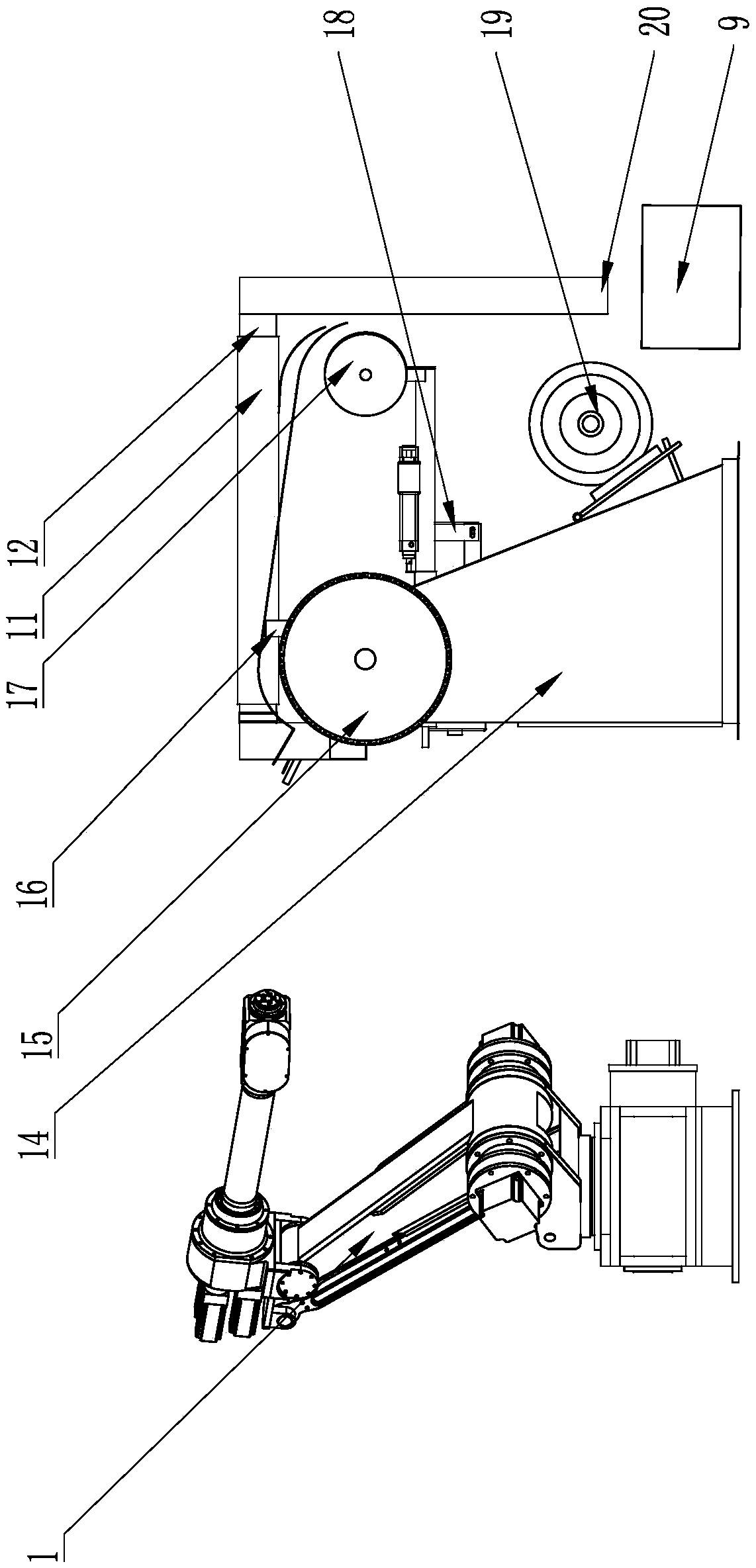

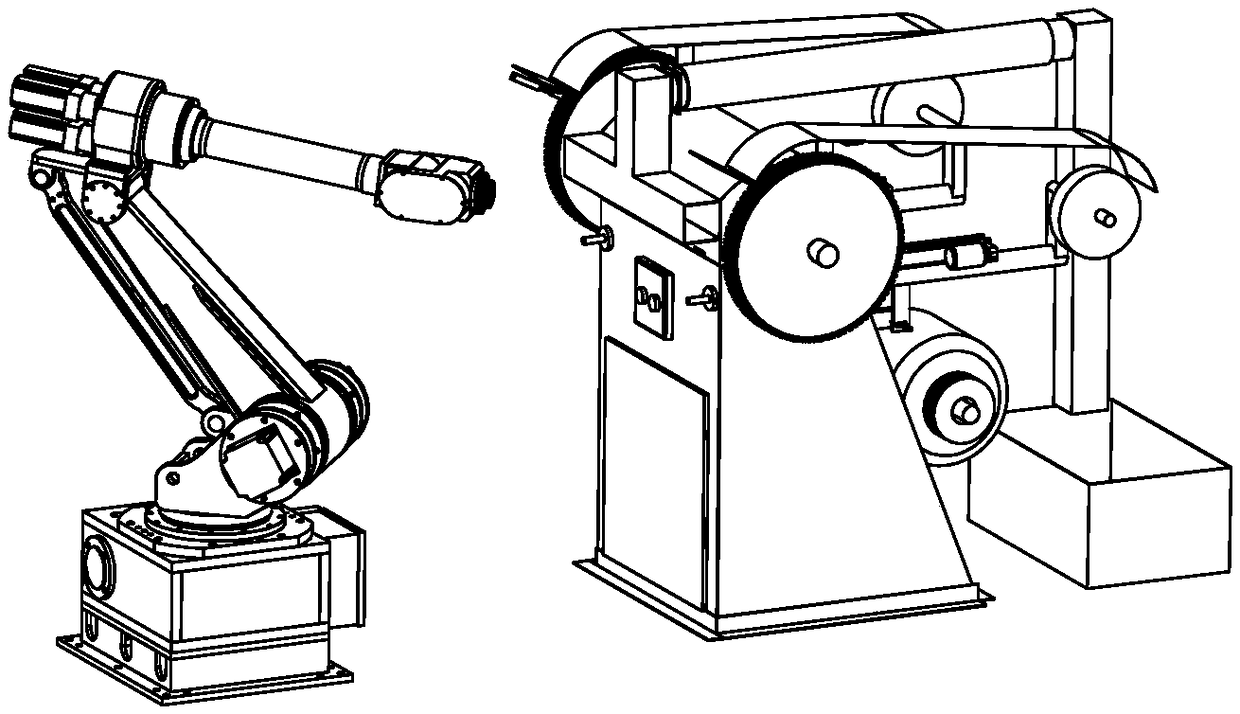

[0039] The present invention is a kind of environmental protection dedusting polishing grinding machine, as figure 1 , 2 , 3, 10, 11, 12, and 13, including a polishing mechanism, an adjustment wheel adjustment device, a dust removal device, a noise reduction device, a waxing device, and a manipulator 1. It is characterized in that: the adjustment wheel adjustment device is on the polishing mechanism , the dust removal device and the noise reduction device are fixedly installed on the polishing mechanism, the noise reduction device is fixed on the dust removal device, the waxing device is installed on the polishing mechanism, and the manipulator 1 is fixed on the position opposite to the polishing mechanism. The polished parts are fixedly mounted on the manipulator 1.

[0040]According to the environmental protection dedusting polishing machine, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com