Ceramic mechanical powder mill

A kind of milling machine and mechanical technology, which is applied in the direction of grain processing, etc., can solve the problems of large limitations and difficult ceramic particles to be evenly ground, and achieve the effect of improving production efficiency and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

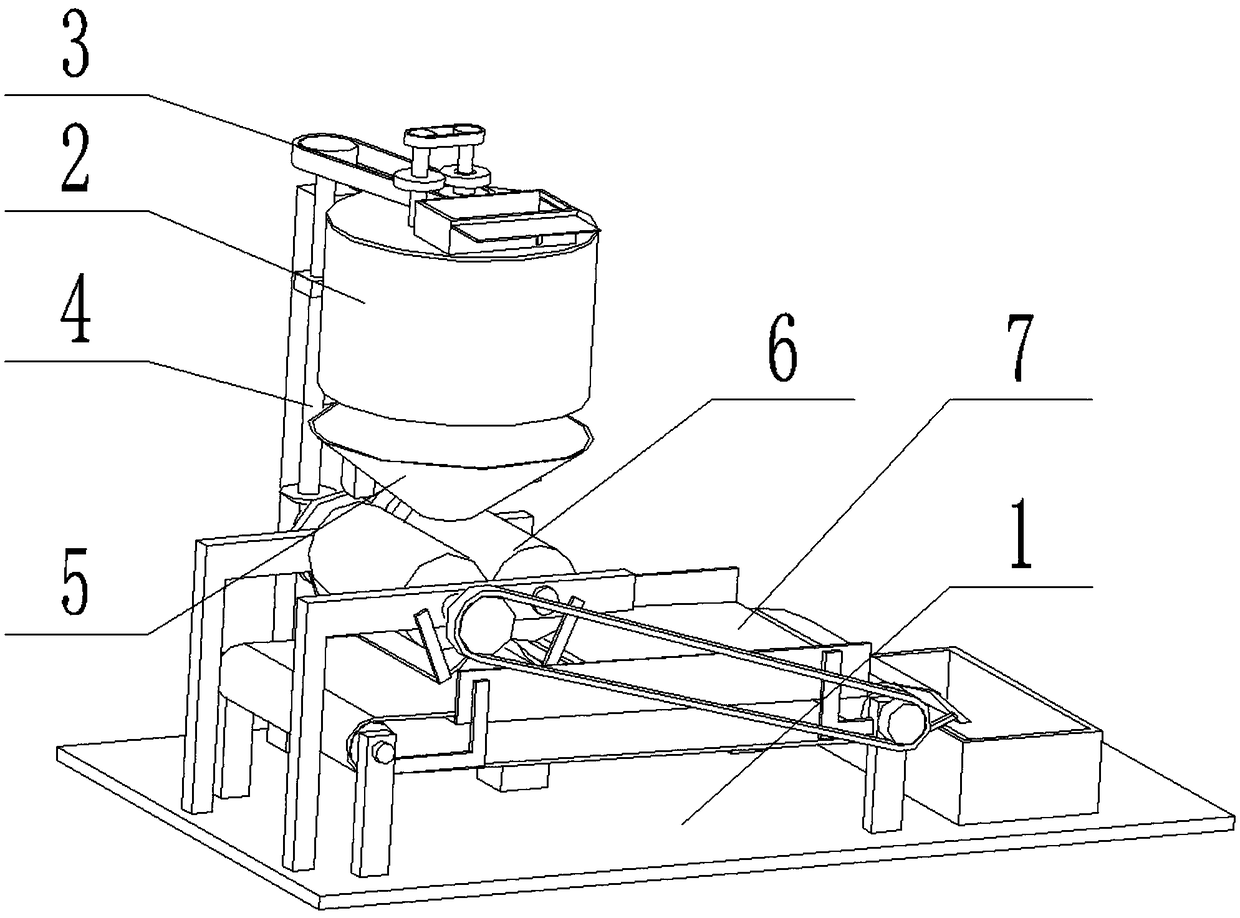

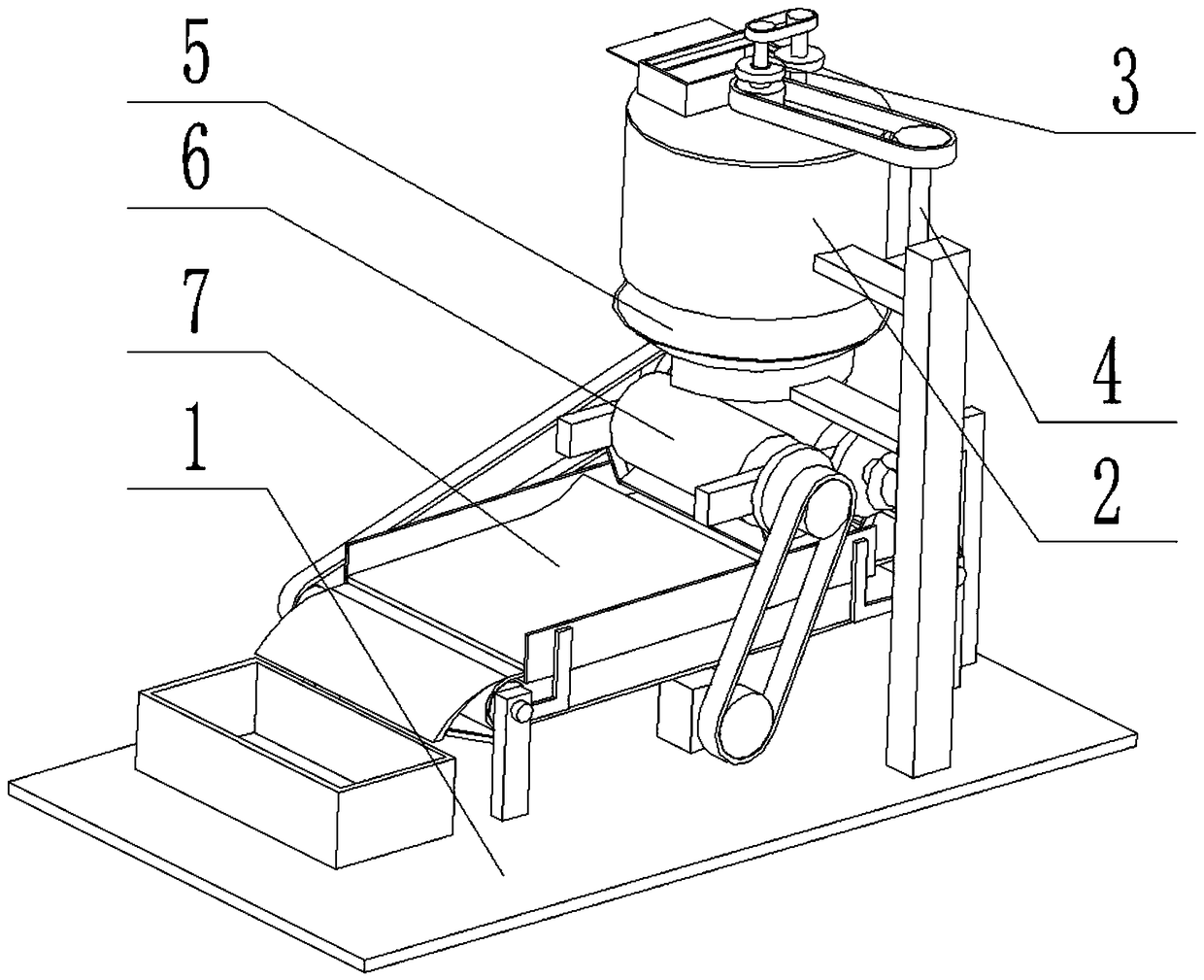

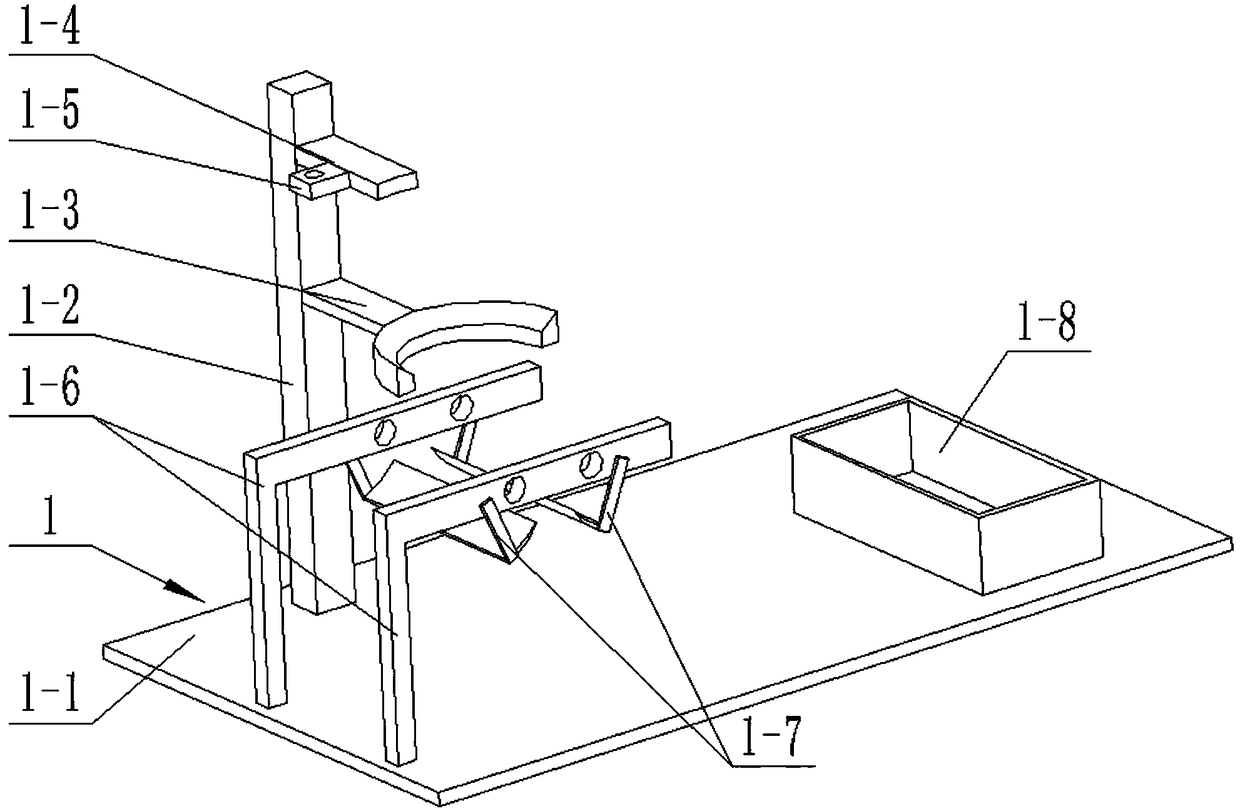

[0033] Such as Figure 1-11 As shown, a ceramic mechanical pulverizer includes a base 1, a grinding cylinder 2, a grinding device 3, a transmission shaft 4, a collection bucket 5 and a grinding drum 6, and the base 1 includes a bottom plate 1-1, a support Rod 1-2, collecting bucket bracket 1-3, grinding tube frame 1-4, transmission shaft frame 1-5 and roller bracket 1-6; pole 1-2 is fixedly connected to one side of bottom plate 1-1; collecting bucket The bracket 1-3 is fixedly connected to the middle end of the support rod 1-2; the grinding cylinder holder 1-4 is fixedly connected to the top of the support rod 1-2; the transmission shaft support 1-5 is fixedly connected to the side of the grinding cylinder holder 1-4 end; there are two roller brackets 1-6, and the two roller brackets 1-6 are symmetrically arranged on both sides of the rear end of the bottom plate 1-1;

[0034] The grinding cylinder 2 includes a grinding cylinder 2-1 and a material inlet 2-2, and the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com