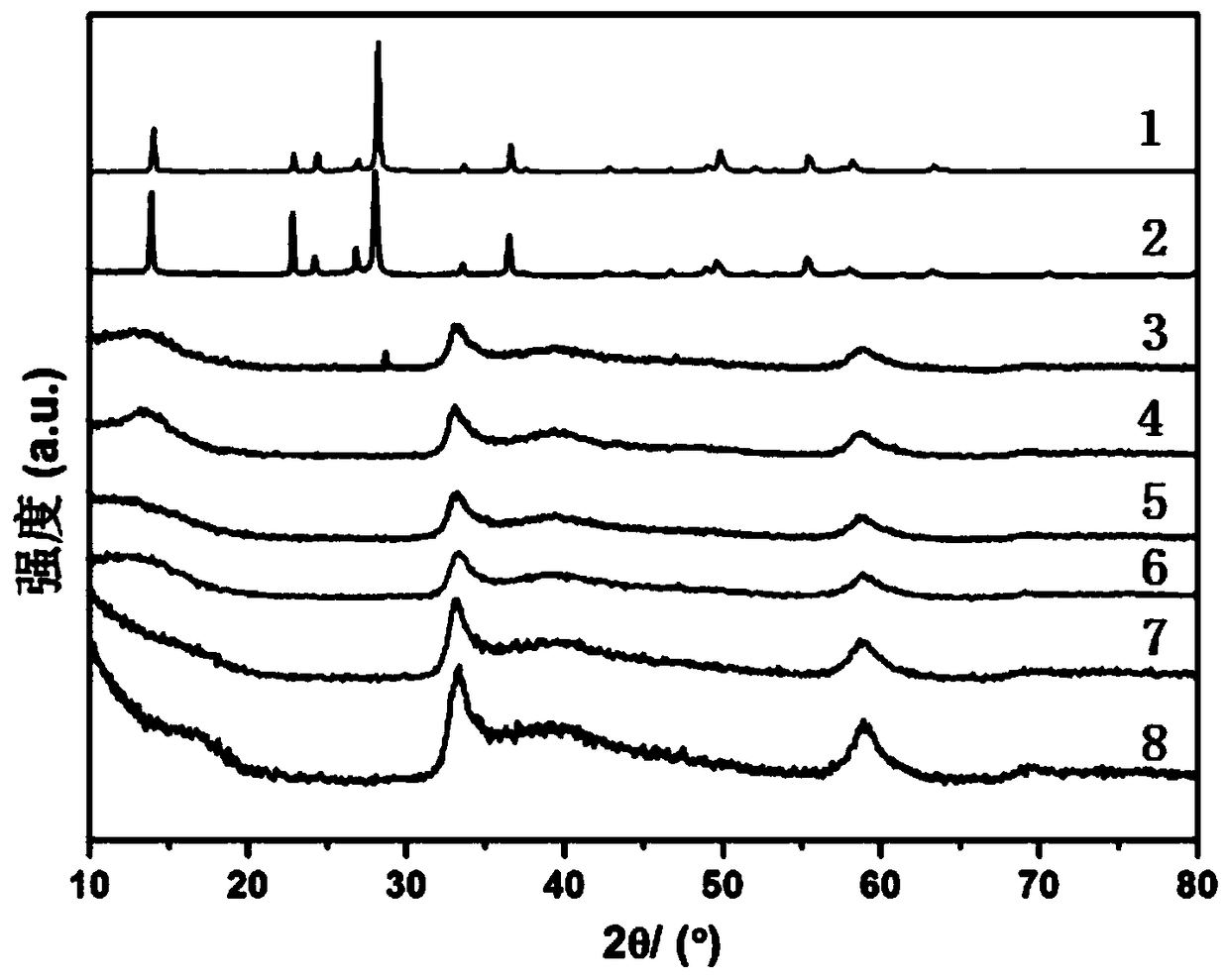

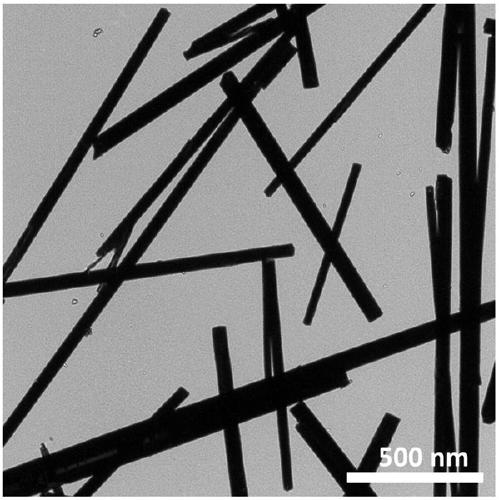

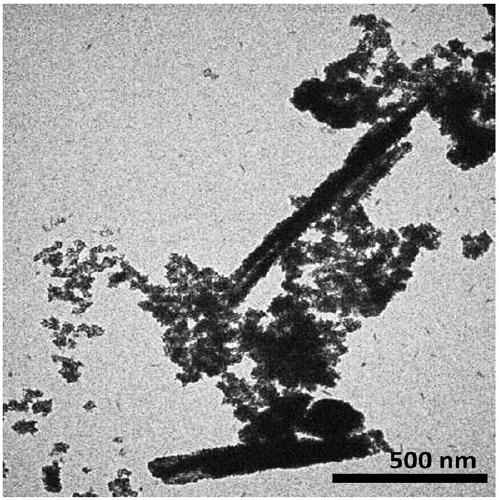

Preparation method and application of tungsten trioxide@molybdenum disulfide hollow tube composite catalyst

A technology of composite catalyst and molybdenum disulfide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic efficiency of visible light, achieve unique morphology, and improve the utilization rate of visible light , The effect of broadening the light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: The preparation method of a tungsten trioxide@molybdenum disulfide hollow tube composite catalyst in this embodiment is specifically carried out according to the following steps:

[0020] 1. Dissolve sodium tungstate and sodium chloride in deionized water and stir magnetically for 10 to 20 minutes. Use HCl solution with a concentration of 3mol / L to adjust the pH to 1 to 3, and then transfer it to a polytetrafluoroethylene liner. Keep it at 160-200°C for 18-26 hours. After the reaction is completed, cool it down to room temperature naturally. Wash it with deionized water for 3-5 times and then with absolute ethanol for 3-5 times. Dry in an oven for 10-14 hours to obtain a light yellow solid that is rod-shaped WO 3 The quality of the sodium tungstate and the volume ratio of deionized water are 1g:(20~25)mL; the quality of the sodium chloride and the volume ratio of deionized water are 1g:(40~50)mL;

[0021] Second, the rod-shaped WO 3 Disperse in deionized...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, an HCl solution with a concentration of 3 mol / L is used to adjust the pH to 2. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the temperature is kept at 200° C. for 4 hours, and the reaction is naturally cooled to room temperature after the reaction is completed. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com