Catalyst for preparing 1,4-butanediol from dimethyl maleate

A dimethyl maleate and catalyst technology, applied in the field of hydrogenation catalysts, can solve the problems of easy aggregation of active metals, influence on catalyst activity and product conversion rate, limited loading of active metals, etc., and increase the roasting temperature and heating rate , Overcoming the effects of mechanical shaping and small catalyst particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

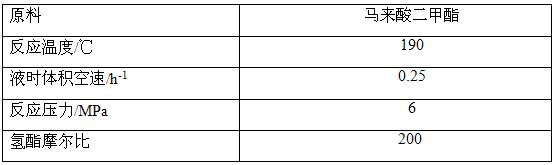

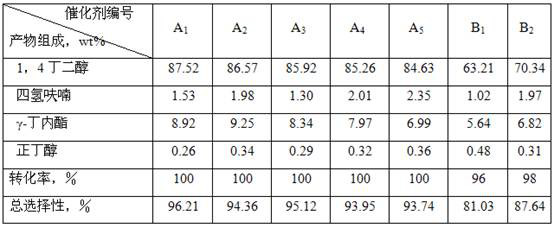

Examples

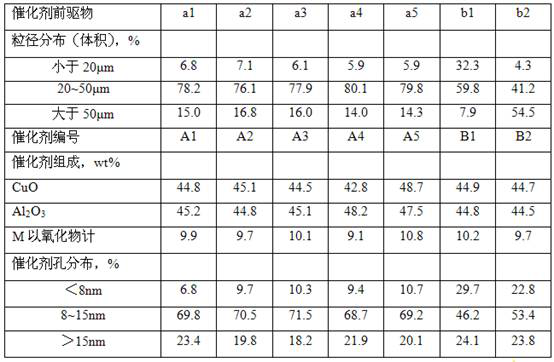

Embodiment 1

[0048] (1) Weigh 230.1g Cu(NO 3 ) 2 . 3H 2 O, 62.9g Zn(NO 3 ) 2 . 6H 2 0 and 12g polyethylene glycol, mixed with 200mL solution;

[0049] (2) Weigh 100g of self-made alumina carrier (specific surface 272, pore volume 0.97);

[0050] (3) Weigh 90mL solution to impregnate the alumina carrier for one stage. After impregnation, the catalyst is dried at 120°C for 4 hours, then weigh 46mL solution for two stage impregnation. After impregnation, the catalyst is dried at 115°C for 5 hours, and finally Weigh 26mL solution for three-stage impregnation. After impregnation, the catalyst is dried at 115°C for 5 hours; after drying, it is roasted. The heating rate is 1.5°C / min at 0-130°C and 0.7°C at 130-180°C. ℃ / min, the heating rate of 180~260℃ is 5℃ / min, the heating rate of 260~500℃ is 2.5℃ / min, and the temperature is kept at 500℃ for 3 hours to obtain the catalyst precursor a1. The properties are shown in Table 1.

Embodiment 2

[0052] Other conditions are the same as in Example 1, except that the quality of polyethylene glycol in the prepared solution is 8g. During the catalyst roasting process, the heating rate at 0~130°C is 1.7°C / min, and the heating rate at 130~180°C is 1.0°C / min. The heating rate at 260 °C was 5.9 °C / min, and the heating rate at 260-500 °C was 2.5 °C / min. The catalyst precursor a2 was obtained, and the catalyst A2 was obtained by tablet molding. Its physical and chemical properties are shown in Table 1.

Embodiment 3

[0054] Other conditions are the same as in Example 1, except that the quality of polyethylene glycol in the prepared solution is changed to 14g. During the catalyst roasting process, the heating rate at 0~130°C is 1.5°C / min, and the heating rate at 130~180°C is 0.8°C / min. The heating rate was 5.0 °C / min from 180 to 260 °C, and 2.7 °C / min from 260 to 500 °C to obtain the catalyst precursor a3, and the catalyst A3 was obtained by tablet molding. Its physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com