Pretilachlor microcapsule suspension and preparation method thereof

A technology of microcapsule suspension and pretilachlor, which is applied in the field of pretilachlor microcapsule suspension and its preparation, can solve the problems of low safety factor and difficult adjustment, and achieve small investment, long duration of drug effect, less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

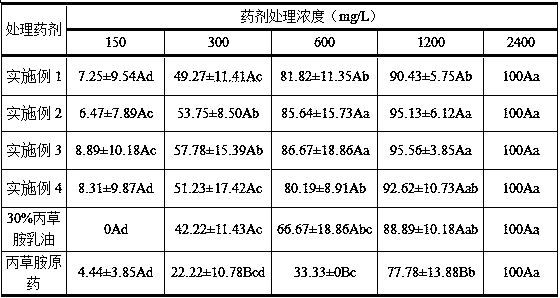

Examples

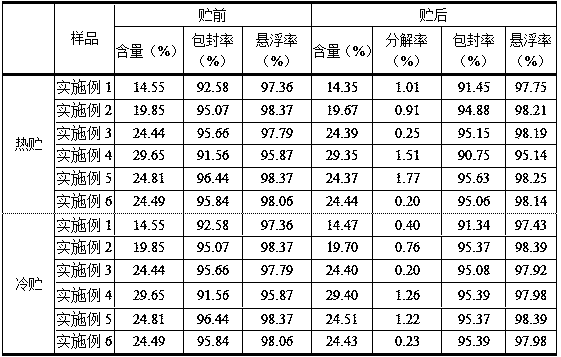

Embodiment 1

[0028] Embodiment 1: 15% pretilachlor microcapsule suspension

[0029] Weigh 15% pretilachlor, 5% capsule wall material PM-200, 6% solvent S-200#, 3.6% emulsifier T-60 (Tween 60), 2% dispersant MF, 6% Aqueous solution of xanthan gum (concentration of xanthan gum is 1%), make up to 100% with water; dissolve pretilachlor, capsule wall material PM-200 and emulsifier T-60 into organic solvent S-200# and stir well, The oil phase was obtained; the dispersant MF was dissolved in water to form a water phase; the oil phase was poured into the water phase and sheared and emulsified at 2500 r / min to obtain an emulsion with an average particle size between 1.5 and 3.5 μm. Gradually raise the temperature under the condition of 35 °C for 1.5 h, 45 °C for 1 h, and 55 °C for 1.5 h, stop heating, add thickener xanthan gum, continue stirring for 1 h to obtain 15% pretilachlor microcapsules suspending agent.

[0030] The content of pretilachlor in the preparation measured by high performance l...

Embodiment 2

[0031] Embodiment 2: 20% pretilachlor microcapsule suspension

[0032] Take by weight 20% pretilachlor, 5% capsule wall material PM-200, 6% solvent S-200#, 3.6% emulsifier T-60, 2% dispersant MF, 6% xanthan gum aqueous solution ( The concentration of xanthan gum is 1%), water is added to 100%; pretilachlor, capsule wall material PM-200 and emulsifier T-60 are dissolved in organic solvent S-200# and stirred to obtain the oil phase; disperse The agent MF was dissolved in water to form a water phase; the oil phase was poured into the water phase, and after shear emulsification at 2500 r / min to obtain an emulsion with an average particle size between 1.5 and 3.5 μm, the temperature was gradually raised under the condition of 200 r / min , react at 35 °C for 1.5 h, at 45 °C for 1 h, and at 55 °C for 1.5 h, stop heating, add thickener xanthan gum, and continue stirring for 1 h to obtain 20% pretilachlor microcapsule suspension.

[0033] The content of pretilachlor in the preparation ...

Embodiment 3

[0034] Embodiment 3: 25% pretilachlor microcapsule suspension

[0035]Take by weight 25% pretilachlor, 5% capsule wall material PM-200, 6% solvent S-200#, 3.6% emulsifier T-60, 2% dispersant MF, 6% xanthan gum aqueous solution ( The concentration of xanthan gum is 1%), water is added to 100%; pretilachlor, capsule wall material PM-200 and emulsifier T-60 are dissolved in the organic solvent S-200# and stirred to obtain the oil phase; disperse The agent MF was dissolved in water to form a water phase; the oil phase was poured into the water phase, and after shear emulsification at 2500 r / min to obtain an emulsion with an average particle size between 1.5 and 3.5 μm, the temperature was gradually raised under the condition of 200 r / min After reacting for 1.5 h at 35 °C, 1 h at 45 °C, and 1.5 h at 55 °C, stop heating and add the thickener xanthan gum, and continue stirring for 1 h to obtain 25% pretilachlor microcapsule suspension.

[0036] The content of pretilachlor in the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com