Staggered-pole rotor of an electric machine

A pole-staggered and rotor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of reducing harmonics, small pole-staggering angle, and increasing the difficulty of the motor, so as to improve motor performance, reduce management costs, and reduce investment. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

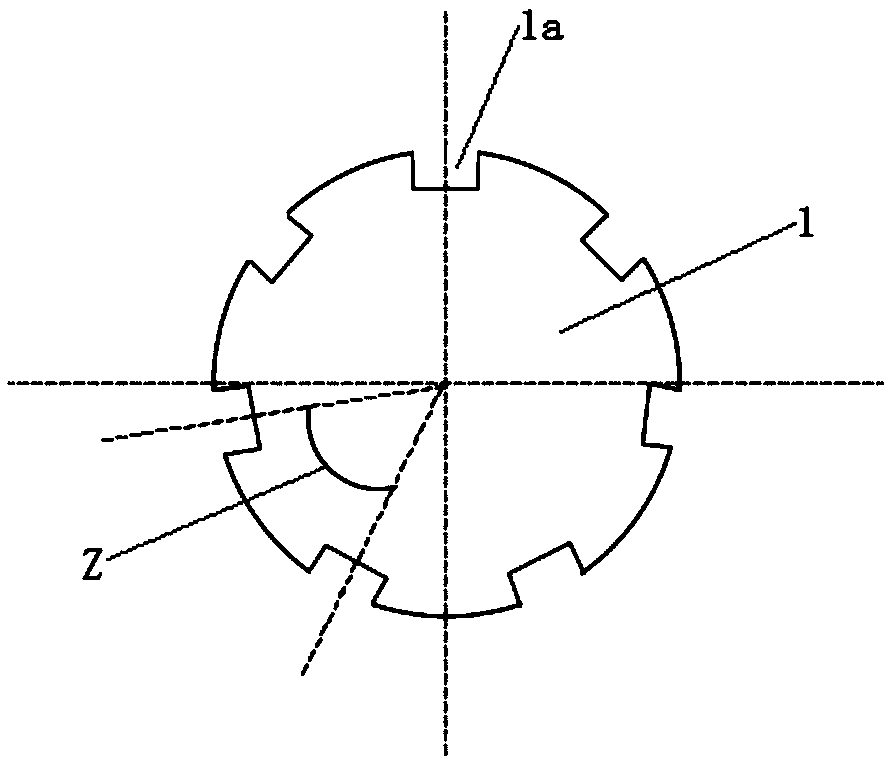

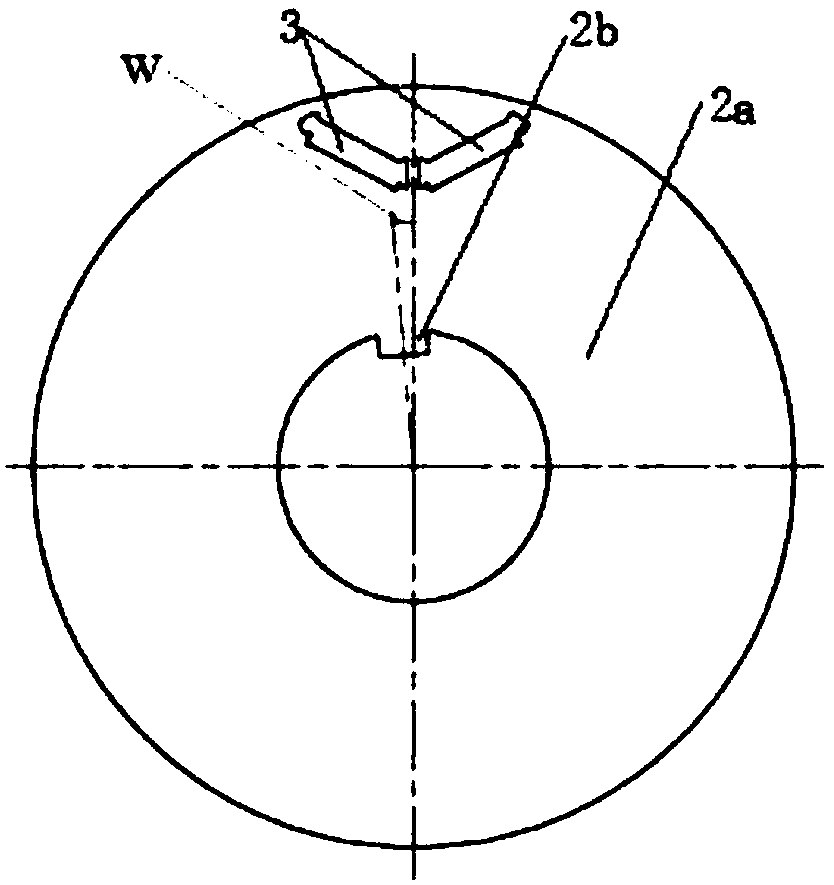

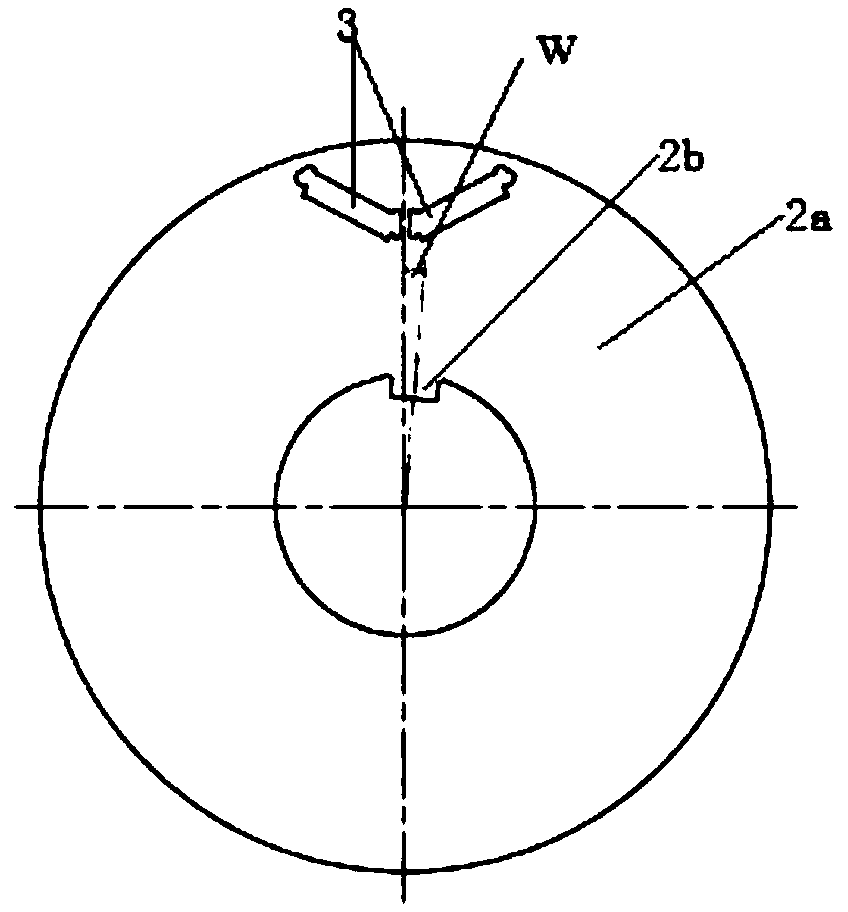

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the embodiment of the present invention discloses a staggered-pole rotor for a motor, which includes: a rotating shaft 1 whose surface is uniformly and vertically provided with n (n≥2, n is an integer) positioning key grooves 1a concaved inward; an iron core 2 , sleeved on the rotating shaft 1, the iron core 2 is composed of 2n ring-shaped sub-cores 2a, the inner ring of each sub-core 2a is provided with a positioning key 2b protruding inward, and each positioning keyway 1a cooperates with the positioning key 2b of the two overlapping sub-cores.

[0026] In this embodiment, multiple pairs of magnetic pole pairs 3 are arranged between the inner ring and the outer ring of the sub-core and evenly arranged on the sub-core around the inner ring, each pair of magnetic pole pairs 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com