Non-marker far-field super-resolution microscopic system and method based on non-diffraction super-resolution beam illumination

A microscopic system and super-resolution technology, applied in the field of visible light microscopy, can solve the problems of limited practical application, short depth of focus, and difficulty in further improving the overall resolution of the system, and achieve strong illumination beam penetration, large working distance, The effect of spreading over a long distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

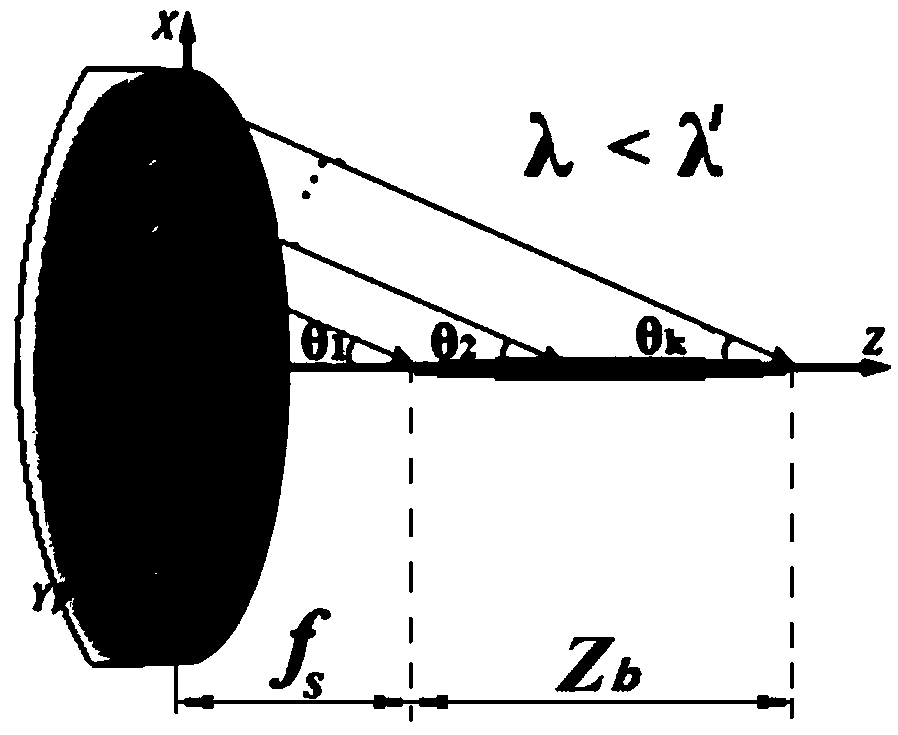

[0028] like figure 1 As shown, the non-marking far-field super-resolution microscopy system based on non-diffraction super-resolution beam illumination proposed by the present invention includes a non-diffraction super-resolution beam illumination module, a sample two-dimensional scanning module, a traditional micro-optical module, and a super-resolution imaging module. module. Its specific structure is as follows:

[0029] The non-diffraction super-resolution beam illumination module is used to generate a non-diffraction super-resolution beam, which includes a laser 1, a fiber coupler 2, an optical fiber 3, a fiber collimator 4, a super-diffraction lens 5, a five-dimensional adjustment mechanism 6, a one-dimensional Nano-displacement piezoelectric stage 7, two-dimensional pitch adjustment mechanism 8 and three-dimensional adjustment mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com