Magnetostrictive metal substrate-based magnetic sonar sensor and preparation method thereof

A magnetostrictive, metal substrate technology, applied in magnetostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc., can solve the difficulty of ensuring the consistency of magnetic sonar sensors, structure and preparation process Complex, difficult to adapt to the device and other problems, to achieve the effect of low loss, simple structure, high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

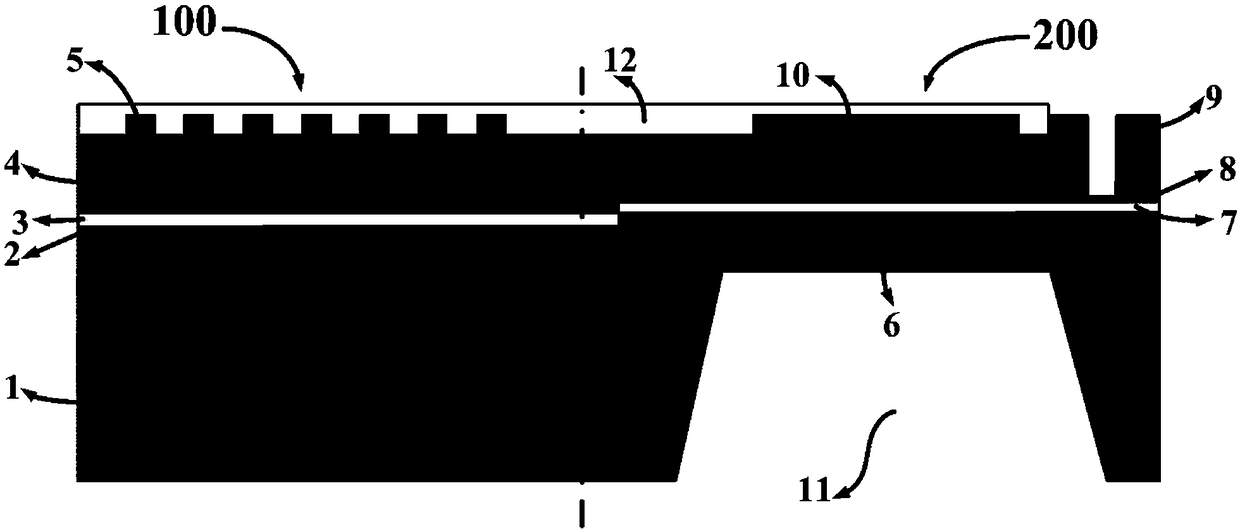

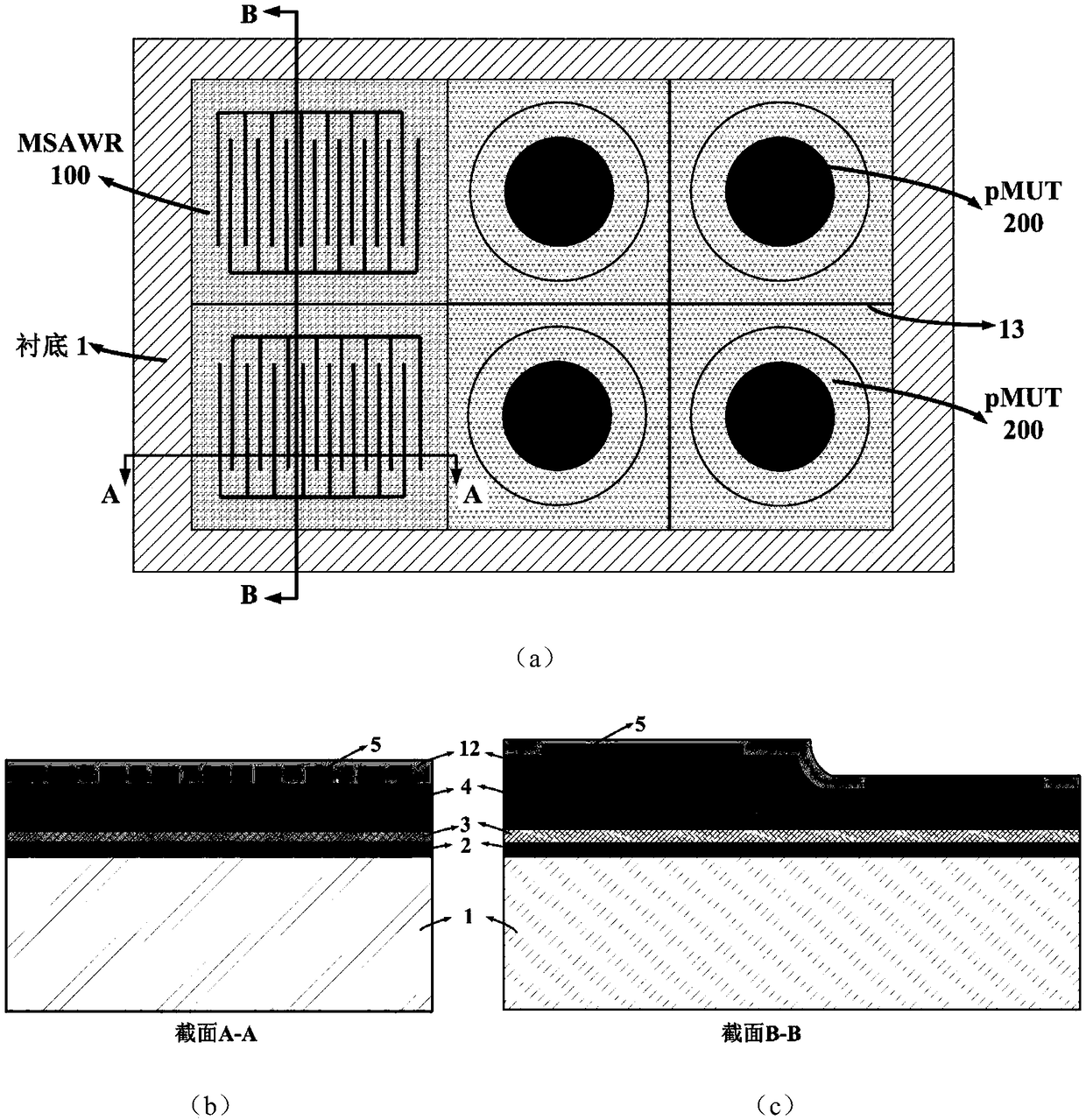

[0051] The preparation method of the magnetic sonar sensor based on the magnetostrictive metal substrate provided by the embodiment, such as Figure 4 shown, including the following steps:

[0052] Step 1. Cleaning:

[0053] Choose 800μm thick Fe 81.3 Ga 18.7 The alloy block is used as the magnetostrictive substrate 1, and its thickness is much greater than twice the wavelength of the surface acoustic wave; 400, 1000, and 3000 mesh sandpaper is used to roughly polish the cut layer on the surface of the magnetostrictive substrate, and the alloy after rough polishing The substrate was ultrasonically cleaned in anhydrous ethanol for 20 minutes, and then polished on the polishing pad with diamond polishing pastes with different particle sizes of 7 μm, 3 μm, and 0.25 μm, and then 50 nm of SiO on the polishing machine. 2 Suspend the polishing solution for polishing for 2 hours. After the polishing is completed, clean the magnetostrictive substrate with absolute ethanol in a high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com