Simple method for identifying aluminum foil and aluminum plated materials in composite film

A composite film and material technology, which is applied in the direction of analysis materials, material inspection products, measuring devices, etc., can solve the problem of not establishing quality control indicators for the identification of aluminum layer materials in composite films, and achieve the effect of high-efficiency technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A simple method for identifying aluminum foil and aluminum-plated materials in composite films, comprising the following steps:

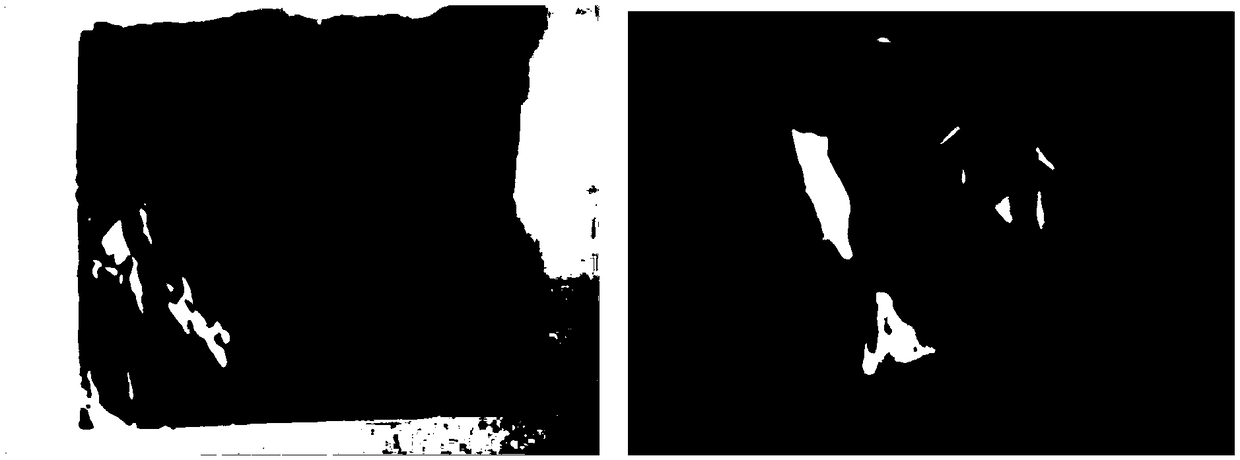

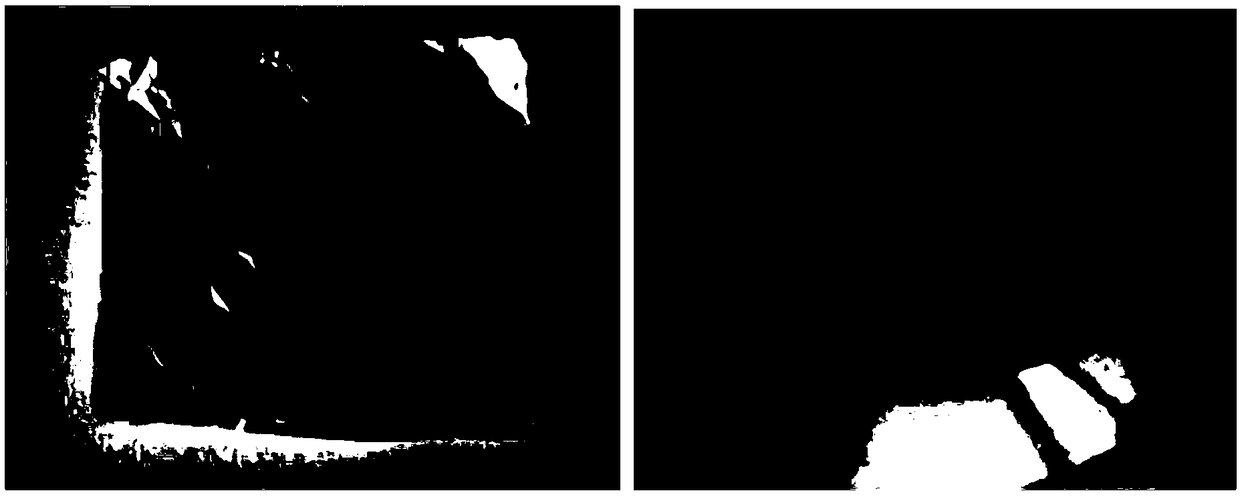

[0034] S1. Cut a 16cm piece from the pure aluminum foil sample and the aluminized polypropylene film sample respectively 2 The sample of pure aluminum foil to be tested and the sample of aluminized polypropylene film to be tested are respectively clamped with metal tweezers at one corner of the sample of pure aluminum foil to be tested and the sample of aluminized polypropylene film to be tested, and placed on the flame of the alcohol lamp Let them burn, and then transfer the pure aluminum foil sample to be tested and the aluminum-coated polypropylene film sample to be tested in a burning state to a porcelain crucible to make them burn completely. After the flame is extinguished and cooled, observe the residue after combustion. form;

[0035] S2. Identification standard: If the residue after burning turns into a mass of gray-black ash or fin...

Embodiment 2

[0038] A simple method for identifying aluminum foil and aluminum-plated materials in composite films, comprising the following steps:

[0039] S1. Cut a piece of 4cm from the polyester / aluminum (aluminum foil) / polyethylene pharmaceutical composite film sample and the biaxially oriented polypropylene / vacuum aluminized cast polypropylene pharmaceutical composite film sample. 2 The polyester / aluminum (aluminum foil) / polyethylene pharmaceutical composite film sample to be tested and the biaxially stretched polypropylene / vacuum aluminized cast polypropylene pharmaceutical composite film sample to be tested were respectively clamped by metal tweezers A corner of the polyester / aluminum (aluminum foil) / polyethylene pharmaceutical composite film sample and the biaxially stretched polypropylene / vacuum aluminized cast polypropylene pharmaceutical composite film sample is placed on the flame of the alcohol lamp to make them Combustion, then the polyester / aluminum (aluminum (aluminum foil...

Embodiment 3

[0043] A simple method for identifying aluminum foil and aluminum-plated materials in composite films, comprising the following steps:

[0044] S1. Samples of polyester / aluminum (aluminum foil) / polypropylene pharmaceutical composite film, polyester / aluminized polyester / polyethylene pharmaceutical composite film and biaxially stretched polypropylene / vacuum aluminized cast polypropylene drug Cut a piece of 25cm from the composite film sample 2 The sample of polyester / aluminum (aluminum foil) / polypropylene pharmaceutical composite film to be tested, the sample of polyester / aluminized polyester / polyethylene pharmaceutical composite film to be tested and the sample of biaxially stretched polypropylene / vacuum aluminized Cast polypropylene pharmaceutical composite film sample, use metal tweezers to clamp the polyester / aluminum (aluminum foil) / polypropylene pharmaceutical composite film sample, the polyester / aluminized polyester / polyethylene pharmaceutical composite film sample to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com