Method for testing residual stress of welding joint based on three-dimensional optical measurement technology and contour method

A measurement technology and three-dimensional optical technology, applied in the field of engineering residual stress measurement, can solve the problems of inability to measure residual stress of workpiece, inability to accurately measure longitudinal stress and transverse stress gradient, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

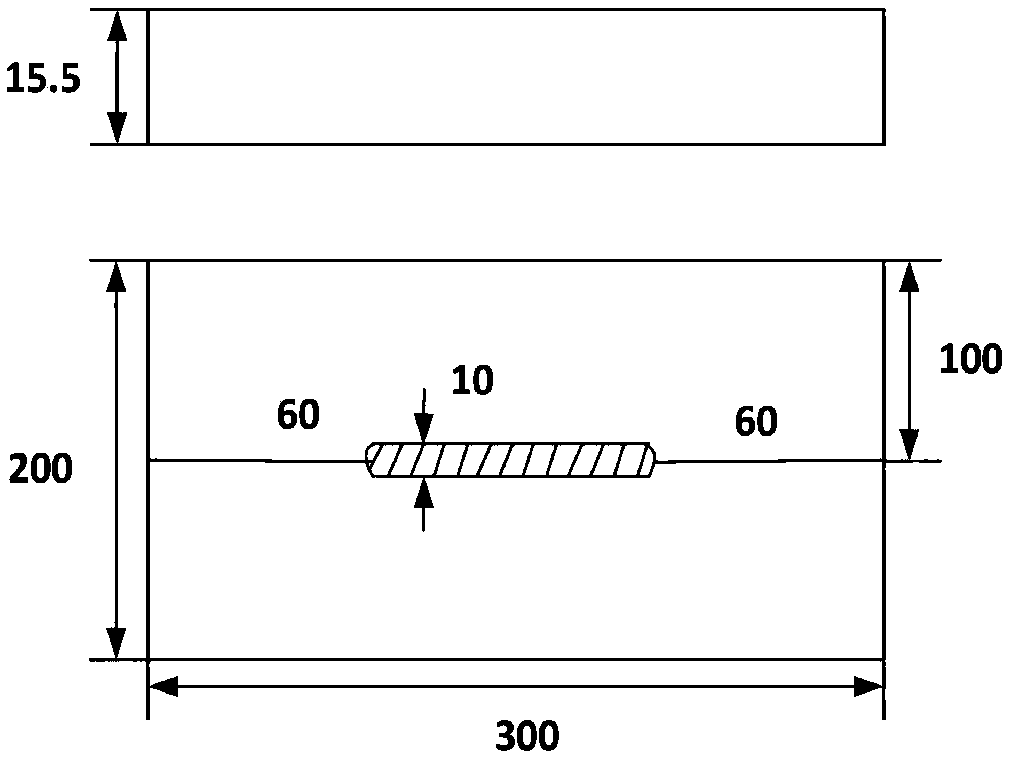

[0045] In this example, if figure 1 As shown, the size of the Q235B steel plate specimen used is 300mm×200mm×15.5mm, and the total length of the weld is 180mm. The experimental inverter DC pulse TIG welding machine WSM-315, the welding torch is fixed on the MOTOMAN six-axis robot to realize automatic welding, using a thoriated tungsten electrode with a diameter of 3.2mm, the tungsten electrode protruding length is 4mm, and the distance between the tip of the tungsten electrode and the test plate The surface is 3mm, the shielding gas is pure argon, the test plate is in an unrestrained state during the welding process, and can be deformed freely. The welding current is 220A, the welding voltage is 17V, and the welding speed is 15cm / min.

[0046] A method for testing the residual stress of welded joints based on three-dimensional optical measurement technology and profilometry, the steps of which are as follows:

[0047] Step 1: Before welding, stress-relief annealing is perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com