Adjoining-pipe liquid spraying defrosting heat source tower heat pump device

A heat source tower heat pump, heat source tower technology, applied in refrigeration and liquefaction, lighting and heating equipment, damage protection and other directions, can solve problems such as miniaturization of unfavorable heat source tower heat pump system and household installation, large space occupation, antifreeze drift and other problems , to overcome the drift after atomization, reduce the space occupied, and solve the effect of drift after atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings.

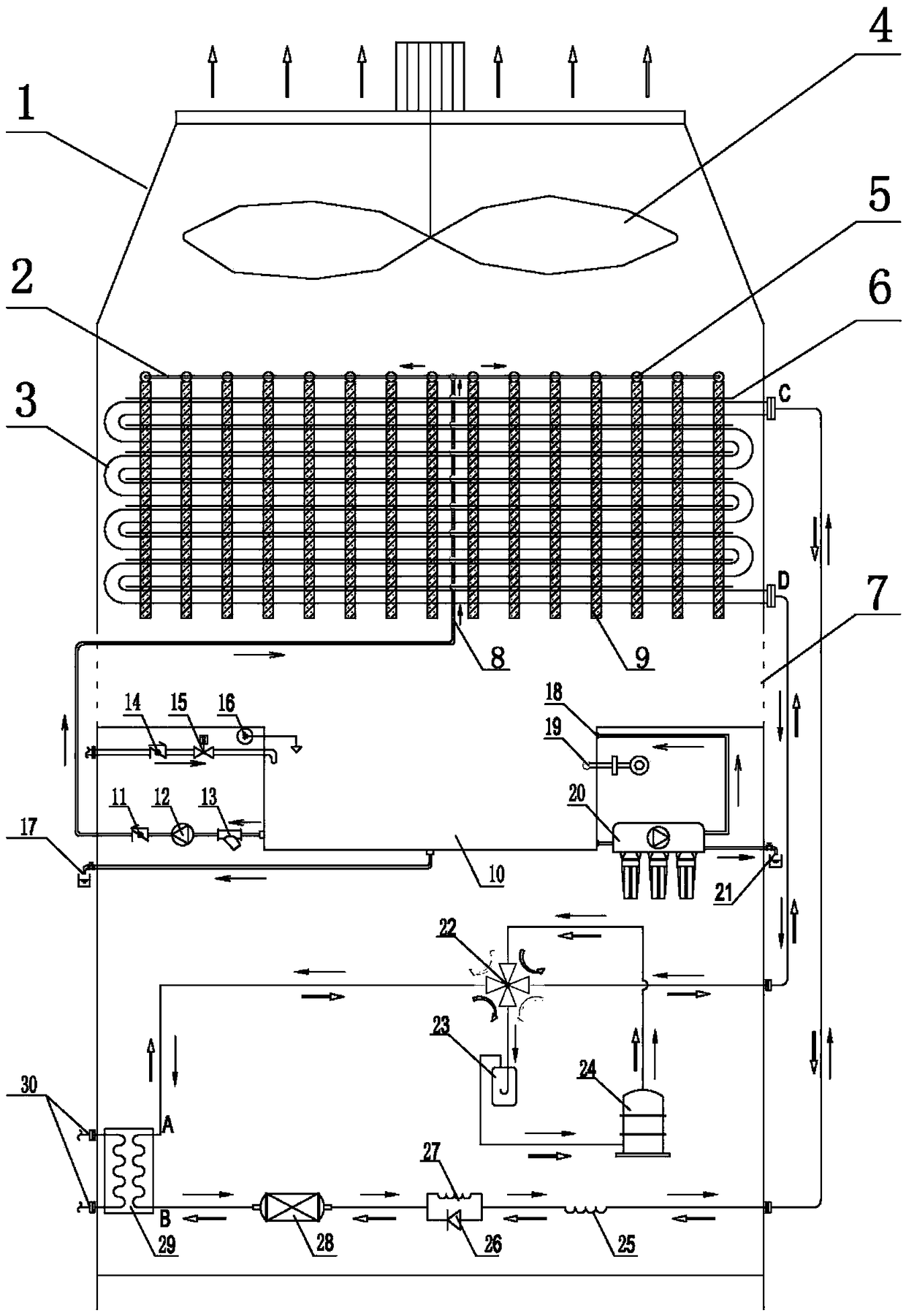

[0020] as attached figure 1 As shown, the present invention includes a heat source tower body 1, a fin accompanying liquid supply pipe 2, a heat exchange coil 3, an exhaust fan 4, several fin accompanying pipes 5, several coil accompanying pipes 6, and a main liquid supply pipe 8 , a number of fins 9, an antifreeze solution pool 10, a liquid supply check valve 11, an antifreeze solution supply pump 12, a filter 13, a replenishment check valve 14, a replenishment solenoid valve 15, a liquid level controller 16, a concentration meter 19, Permeable membrane equipment 20, four-way valve 22, gas-liquid separator 23, compressor 24, capillary, dry filter 28, heat exchanger 29, characterized in that: heat exchange coil 3, exhaust fan 4, antifreeze solution pool 10 , antifreeze solution supply liquid pump 12, filter 13, permeable membrane equipment 20, gas-liquid separator 23, compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com