Absorbable pulling rivet

A technology of pulling rivets and rivets, which is applied in the direction of rivets, screws, threaded fasteners, etc., and can solve problems such as inconsistent nail bodies, offset misalignment, and poor fixation stability, so as to avoid offset misalignment, ensure stability, and delay sliding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

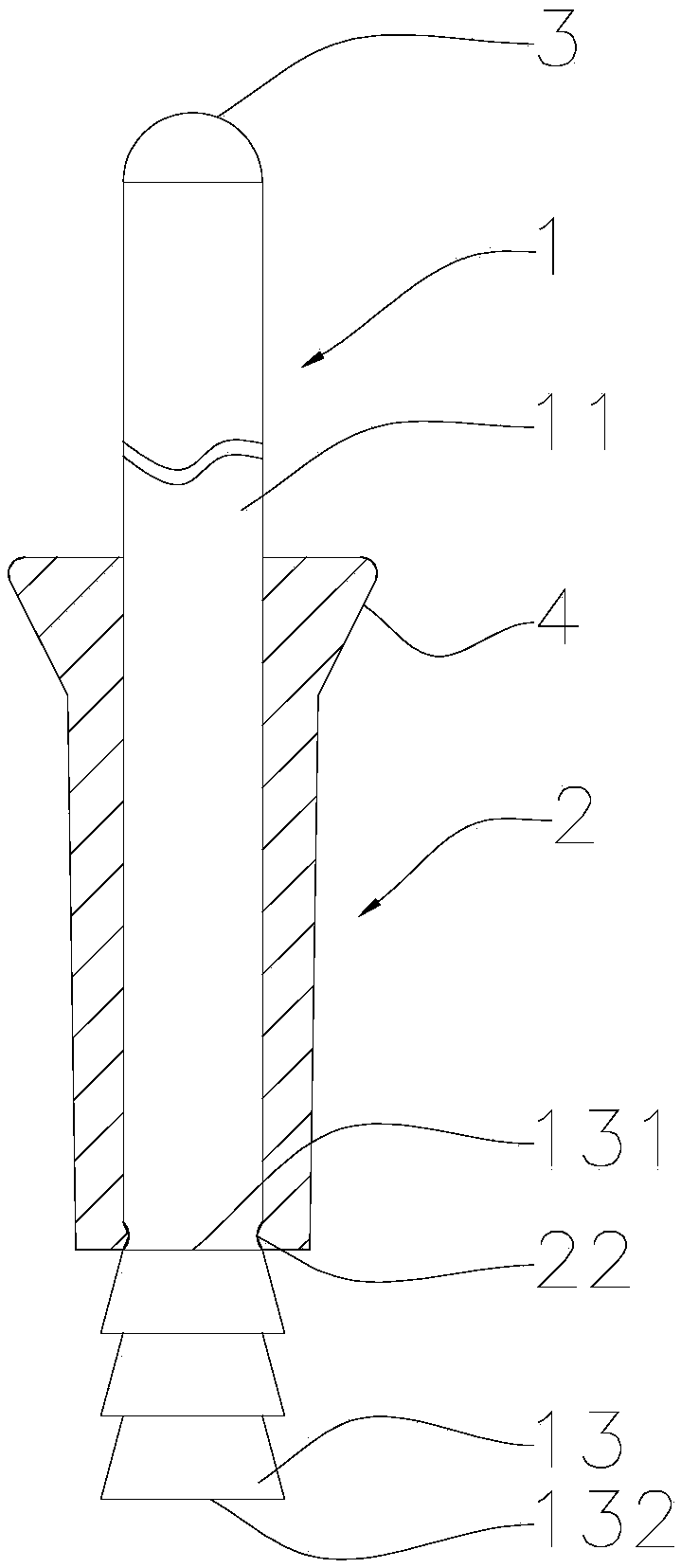

[0029] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

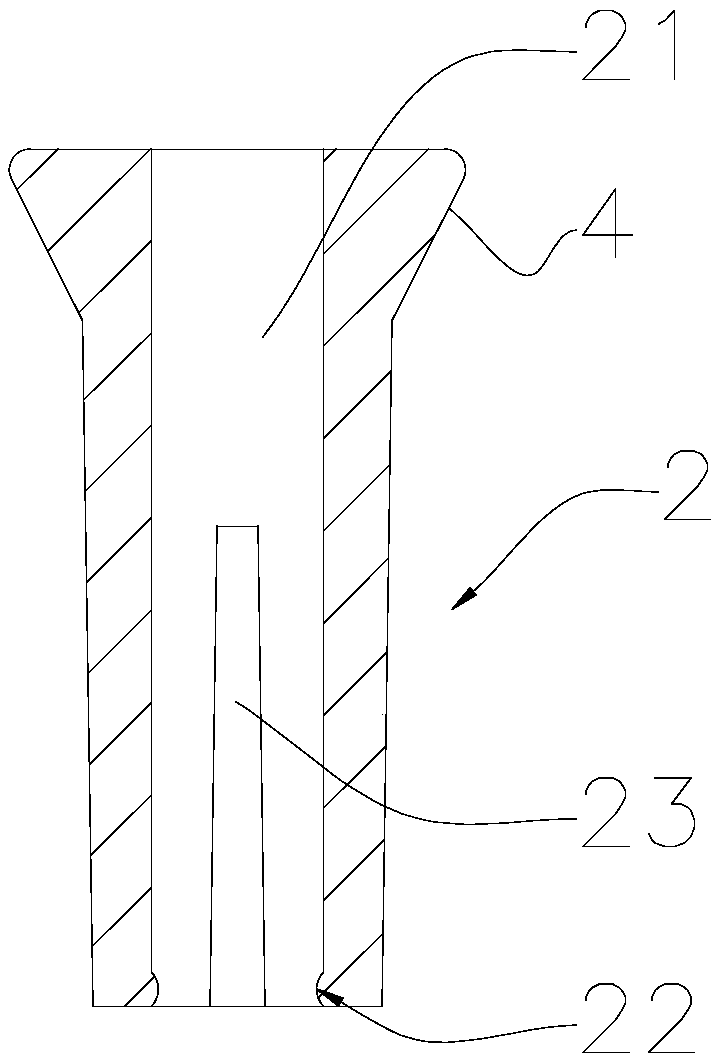

[0030] Such as Figure 1-3 As shown, the present invention provides an absorbable blind rivet 1, comprising a rivet 1 and a rivet tube 2,

[0031] The rivet tube 2 has a hollow channel 21 for the rivet 1 to pass through, the inner side wall of the rivet tube 2 has an annular protrusion 22, and the side wall of the rivet tube 2 is provided with a number of expansion grooves 23 for the expansion of the rivet tube 2;

[0032] The rivet 1 includes a nail body 11 and an expansion body. The diameter of the nail body 11 is the same as that of the hollow channel 21 of the rivet tube 2. The maximum diameter of the expansion body is larger than the diameter of the nail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com