System and method for nuclear energy coupling chemical energy power generation based on two-circuit boiler

A technology of chemical energy and boiler, applied in the field of nuclear energy coupling chemical energy power generation system, can solve the problems of coupled boiler design and operation safety, low steam grade, low power generation efficiency, etc., to improve cycle thermal efficiency and power generation efficiency , fast load response, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

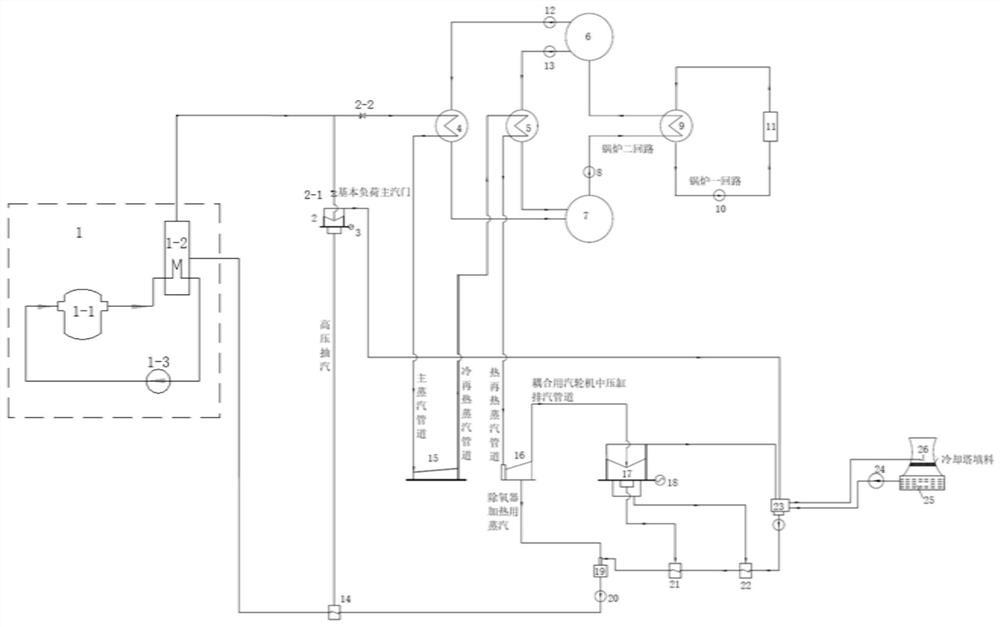

[0042] In one or more embodiments, a nuclear energy coupled chemical energy power generation system based on a two-circuit boiler is disclosed, such as figure 1 As shown, it includes: nuclear island 1, boiler 11, gas-molten salt heat exchanger 9, hot molten salt tank 6, cold molten salt tank 7, cold molten salt pump 8, hot molten salt pump 12 for superheated steam, reheating Hot molten salt pump for steam 13, molten salt-superheated steam heat exchanger 4, molten salt-reheated steam heat exchanger 5, steam turbine with base load 2, first generator 3, coupling steam turbine, second generator 18 , Low pressure heater, high pressure heater 14, deaerator 19, condenser 23, cooling tower 26, circulating water pump 24, feed water pump 20, etc.

[0043] The nuclear island 1 includes a nuclear reactor 1-1, a primary circuit main pump 1-3 of the nuclear island, a steam generator 1-2, and the like. The feed water entering the nuclear island 1 is heated by the steam generator 1-2 and the...

Embodiment 2

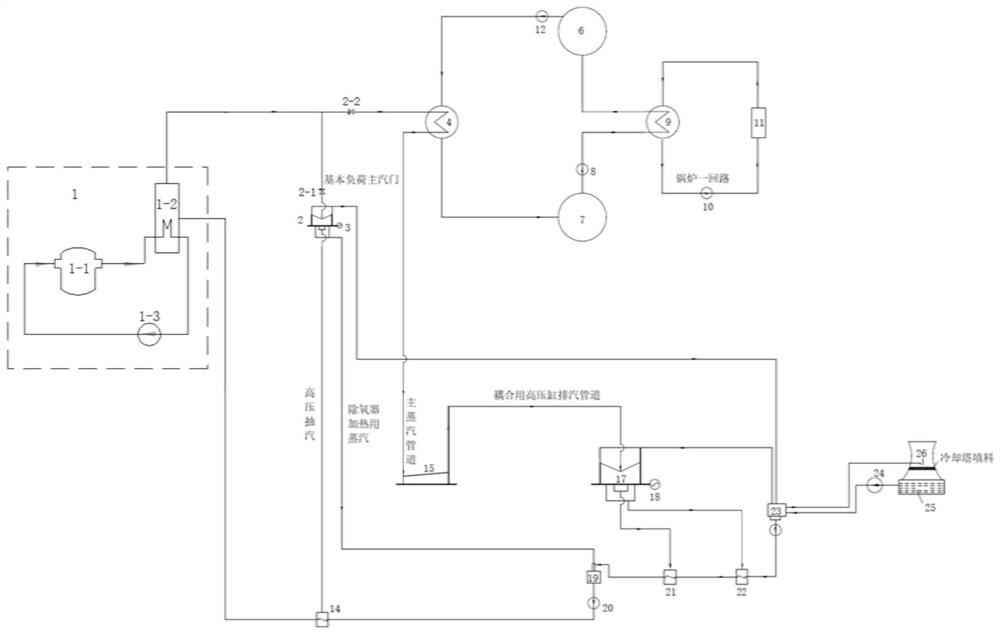

[0064] In one or more embodiments, a nuclear energy coupled chemical energy power generation system based on a two-circuit boiler is disclosed, such as figure 2 As shown, it includes: nuclear island 1, boiler 11, gas-molten salt heat exchanger 9, hot molten salt tank 6, cold molten salt tank 7, cold molten salt pump 8, hot molten salt pump 12 for superheated steam, molten salt - superheated steam heat exchanger 4, steam turbine with base load 2, first generator 3, coupling steam turbine, second generator 18, low pressure heater, high pressure heater 14, deaerator 19, condenser 23, cooling Tower 26, circulating water pump 24, feed water pump 20, etc.

[0065] The nuclear island 1 includes a nuclear reactor 1-1, a primary circuit main pump 1-3 of the nuclear island, a steam generator 1-2, and the like. The feed water entering the nuclear island 1 is heated by the steam generator 1-2 and then evaporated into saturated steam or wet steam with a dryness greater than 0.9.

[0066...

Embodiment 3

[0086] In one or more embodiments, a method for nuclear energy coupled chemical energy power generation based on a two-circuit boiler is disclosed, including: the boiler 11 burns chemical energy fuels (fossil fuels such as coal, oil, natural gas, etc., and biomass, Garbage and other renewable energy fuels, etc.) convert chemical energy into thermal energy, and transfer the thermal energy through special gases (such as helium, supercritical carbon dioxide, etc.), and the low-temperature gas (such as helium with a temperature below 500°C) at the boiler inlet Gas or supercritical carbon dioxide, etc.), the boiler outlet is high-temperature gas (such as helium or supercritical carbon dioxide with a temperature range of 500-700 ° C), and the gas circulation power is provided by the gas circulation fan 10 located at the boiler inlet.

[0087] The feed water enters the nuclear island 1 after being heated in the high-pressure heater 14, and is heated and evaporated in the nuclear islan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com