Steam turbine cycle

A technology of steam turbines and turbines, applied in steam applications, steam engine devices, machines/engines, etc., to achieve high cycle thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

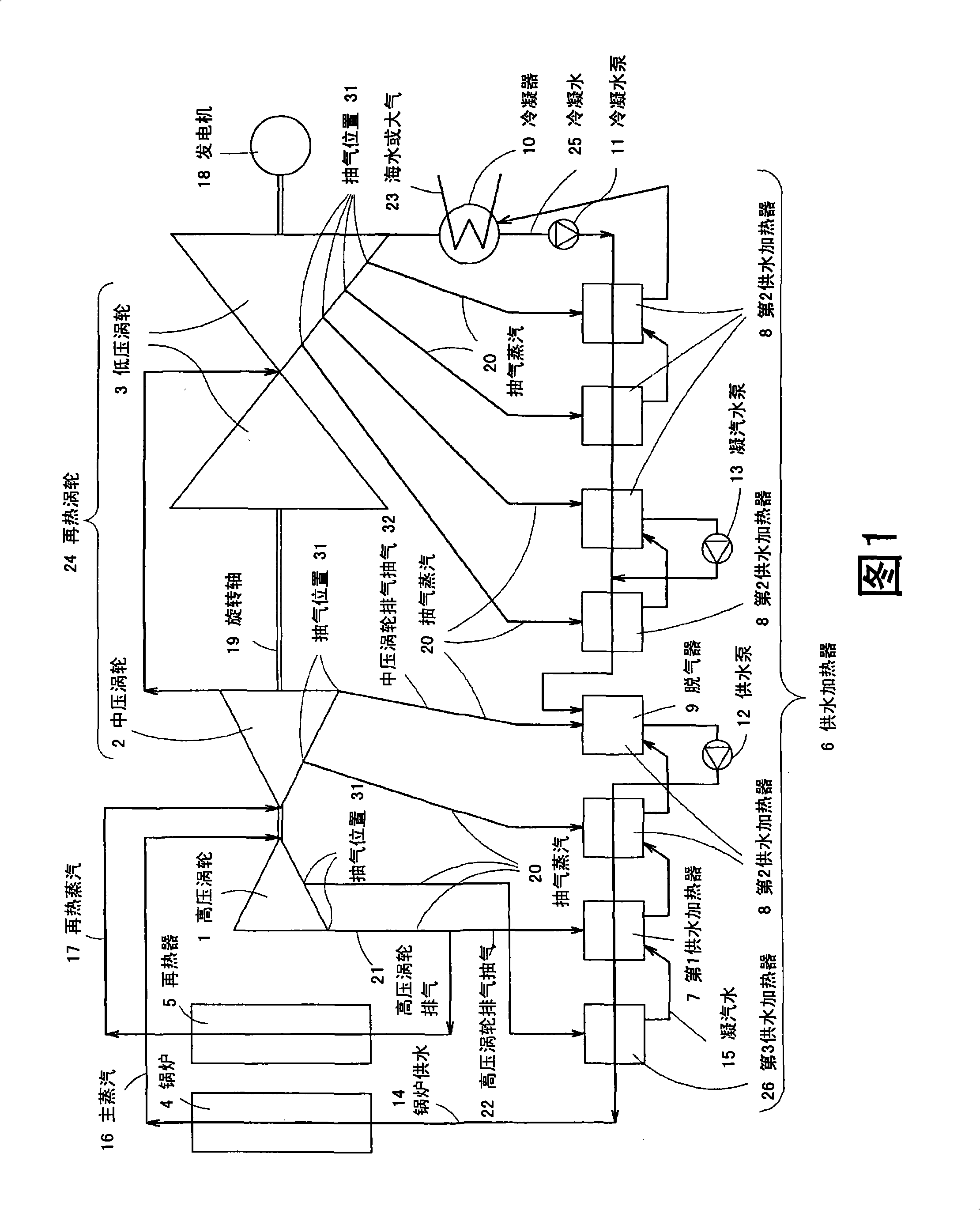

[0029] Hereinafter, a first embodiment of the steam turbine cycle of the present invention will be described with reference to the drawings. Here, FIG. 1 is a diagram showing a first embodiment of the present invention.

[0030] The steam turbine cycle of the present embodiment constitutes a Rankine cycle, the Rankine cycle is a first-stage reheating cycle in which the working fluid is water, and is a regenerative cycle, and has: a high-pressure turbine 1; a reheating turbine 24; a boiler 4; a water supply heater 6. The water supplied to the boiler 4 is heated by the extraction steam from the high-pressure turbine 1 and the reheat turbine 24 ; the water supply pump 12 ; and the condenser 10 .

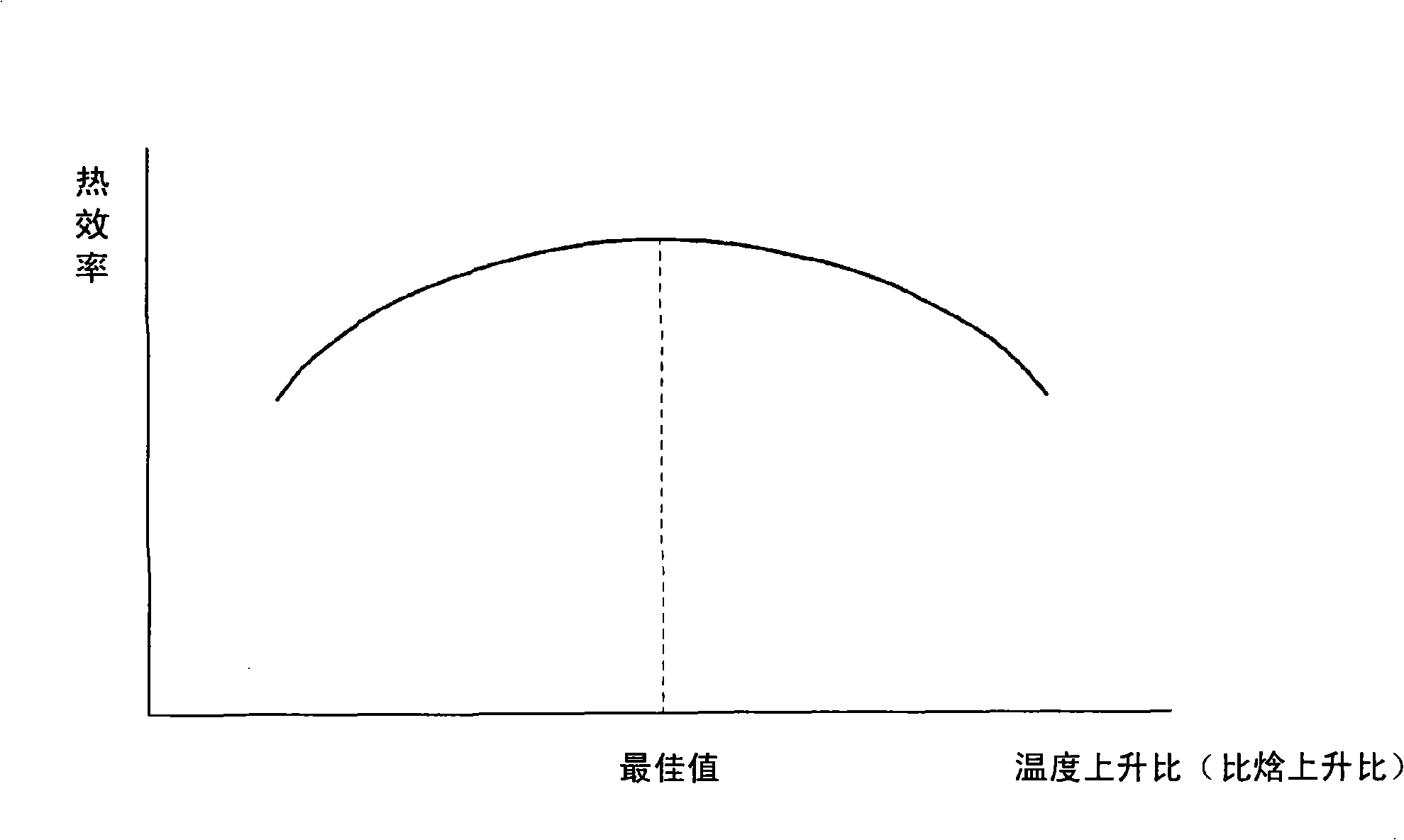

[0031] And, the temperature of the steam at the outlet of the boiler 4 is above 590° C., and the temperature rise ratio is above 1.9 and below 3.5; The corresponding ratio of the increase in the temperature of the supplied water from the first feed water heater 7 to the increase in the...

no. 2 Embodiment approach

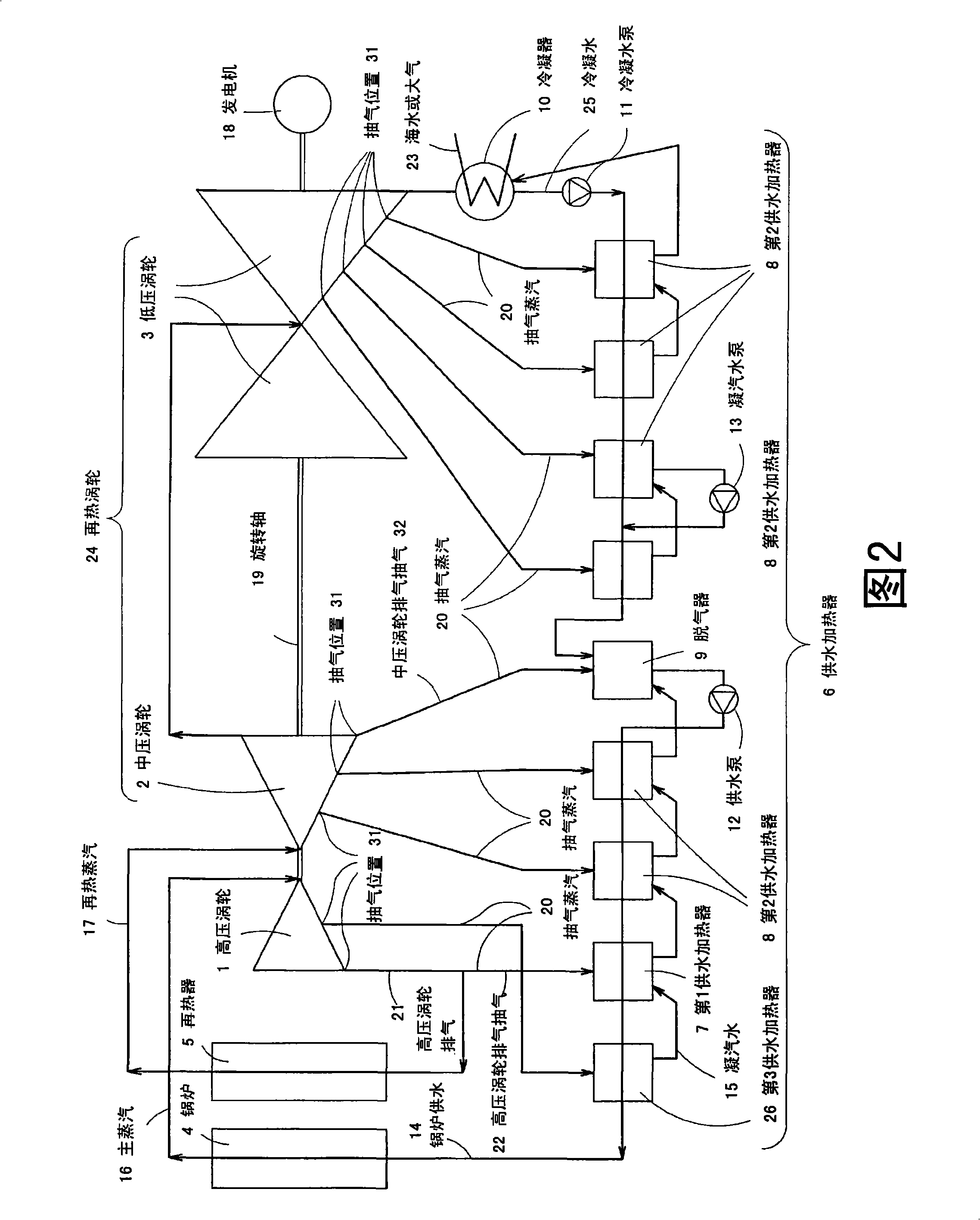

[0043] Next, a second embodiment of the present invention will be described with reference to FIG. 1 .

[0044] The steam turbine cycle of the present embodiment constitutes a Rankine cycle, the Rankine cycle is a first-stage reheating cycle in which the working fluid is water, and is a regenerative cycle, and has: a high-pressure turbine 1; a reheating turbine 24; a boiler 4; a water supply heater 6. The water supplied to the boiler 4 is heated by the extraction steam from the high-pressure turbine 1 and the reheat turbine 24 ; the water supply pump 12 ; and the condenser 10 .

[0045] Moreover, the steam temperature at the outlet of the boiler 4 is above 590° C., and the specific enthalpy increase ratio is above 1.9 and below 3.5; The ratio of the increase in the specific enthalpy of the supplied water to the increase in the average specific enthalpy of the supplied water of the second feed water heater 8 whose water supply pressure is lower than that of the first feed water...

no. 3 Embodiment approach

[0053] Next, a third embodiment of the present invention will be described with reference to FIG. 1 .

[0054] The steam turbine cycle of the present embodiment constitutes a Rankine cycle, the Rankine cycle is a first-stage reheating cycle in which the working fluid is water, and is a regenerative cycle, and has: a high-pressure turbine 1; a reheating turbine 24; a boiler 4; a water supply heater 6. The water supplied to the boiler 4 is heated by the extraction steam from the high-pressure turbine 1 and the reheat turbine 24 ; the water supply pump 12 ; and the condenser 10 .

[0055] Moreover, the steam temperature at the outlet of the boiler 4 is above 590°C, and the temperature rise ratio is above 1.9 and below 3.5; The ratio of rise to the average feed water temperature rise of the feed water heaters other than the first feed water heater 7.

[0056] Here, the water heaters other than the first water heater 7 refer to the second water heater 8 that supplies water at a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com