Fast die erecting device for closed wall and construction method

A construction method and airtight wall technology, applied in mining equipment, earth square drilling, mining equipment, etc., can solve problems such as easy cracking and air leakage, reduce construction efficiency, and increase airtight cost, so as to achieve easy promotion, improve airtight efficiency, and reduce airtightness cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

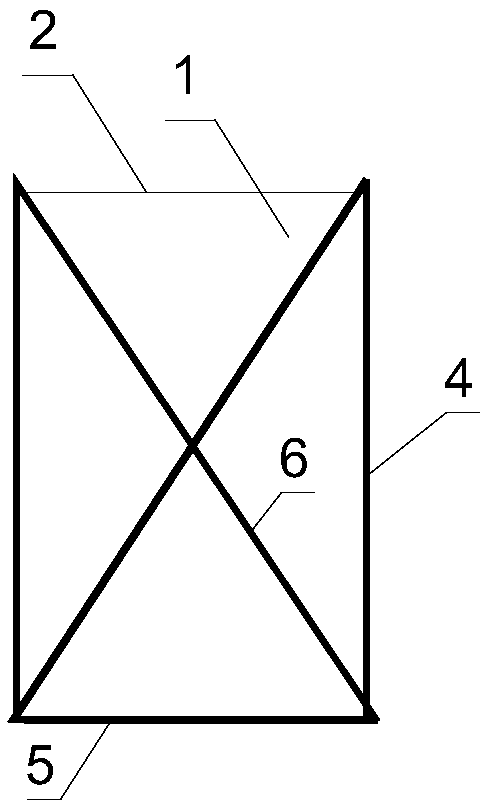

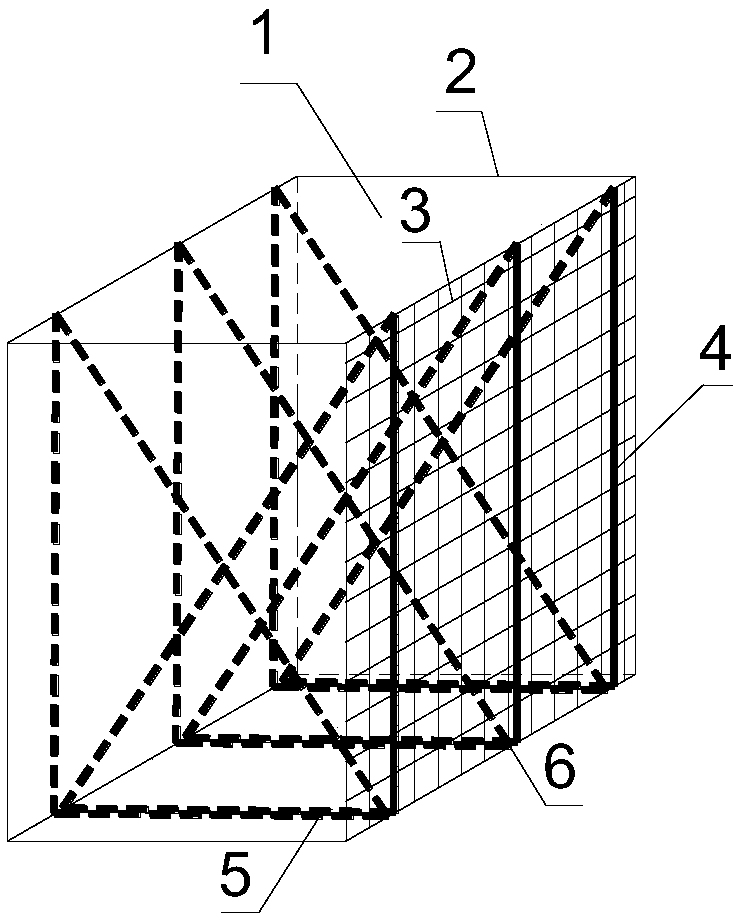

[0025] refer to Figure 1-4 , a closed wall rapid formwork device, comprising a closed wall wall 1, the rapid formwork device is composed of a vertical bar 4, a horizontal bar 5, an oblique bar 6, the vertical bar 4, horizontal bar 5, The oblique rods 6 are connected in a hinged manner, the vertical rods 4 are vertically placed on the bottom plate of the airtight wall body 1, the horizontal rods 5 are fixed on the bottom plate of the airtight wall body 1, and the oblique rods 6 pass through The flexible airtight bag 2 is connected with the horizontal bar 5 and the vertical bar 6 to form a tripod structure, and a steel mesh 3 is placed between the vertical bar 4 and the flexible airtight bag 2 .

[0026] In this embodiment, the specifications of the airtight wall body 1 are set to be 4000 mm wide x 3000 mm high x 1500 mm thick.

[0027] ①According to the section size of the roadway, use φ50×5mm steel pipe to process 6 vertical rods 4 with a length of 3000mm, horizontal rods 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com