A pulse current method for rapid preparation of grain-oriented thin strip electrical steel at room temperature

A pulse current, electrical steel technology, applied in the field of rapid preparation of oriented thin strip electrical steel, can solve the problems of high required temperature, long preparation time, complicated means, etc., and achieve the effect of saving energy and reducing temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, a pulse current annealing treatment is performed on a 0.1 mm cold-rolled oriented thin-strip electrical steel. Specific steps are as follows:

[0020] Step 1: Take a 30mm×5mm×0.1mm cold-rolled sample and grind both ends to ensure good contact with the pulse electrode.

[0021] Step 2: Set the parameter range of the pulse current, and determine the pulse current parameters as 100Hz, 150μs, 200A.

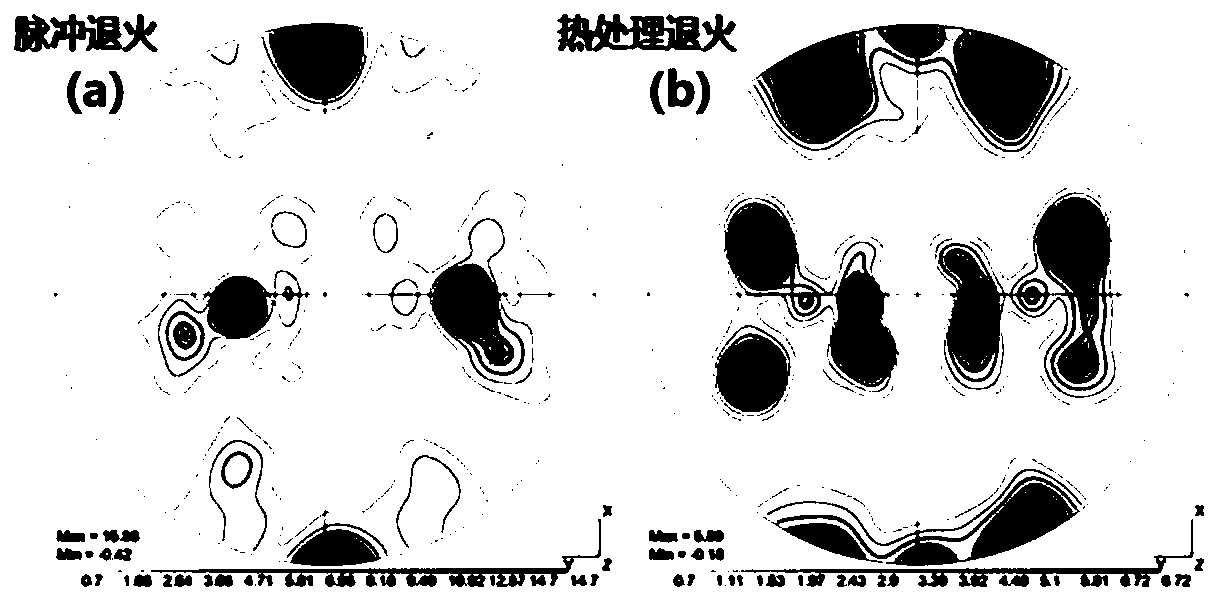

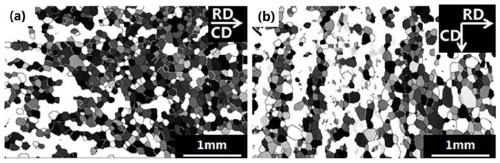

[0022] Step 3: Apply MgO coating evenly on the cold-rolled sample and fix it at the output end of the pulse power supply with a fixture so that the current direction is parallel to the rolling direction, and perform pulse current annealing treatment for 5 minutes. At the same time, according to the pulse parameters under the test The temperature of the sample was raised to 680°C, and the sample was annealed in a resistance furnace at 680°C for 5 minutes. The EBSD characterization of the samples after pulse current annealing treatment and the samples after ...

Embodiment 2

[0024] In this embodiment, a pulse current annealing treatment is performed on a 0.1 mm cold-rolled oriented thin-strip electrical steel. Specific steps are as follows:

[0025] Step 1: Take a 30mm×5mm×0.1mm cold-rolled sample and grind both ends to ensure good contact with the pulse electrode.

[0026] Step 2: Set the parameter range of the pulse current, and determine the pulse current parameters as 125Hz, 200μs, 200A.

[0027] Step 3: Apply MgO coating evenly on the cold-rolled sample and fix it at the output end of the pulse power supply with a fixture so that the current direction is parallel to the rolling direction, and perform pulse current annealing treatment for 5 minutes. At the same time, according to the pulse parameters under the test The temperature of the sample was raised to 800°C, and the sample was annealed in a resistance furnace at 800°C for 5 minutes. The EBSD characterization of the samples after pulse current annealing treatment and the samples after ...

Embodiment 3

[0029] In this embodiment, a pulse current annealing treatment is performed on a 0.1 mm cold-rolled oriented thin-strip electrical steel. Specific steps are as follows:

[0030] Step 1: Take a 30mm×5mm×0.1mm cold-rolled sample and grind both ends to ensure good contact with the pulse electrode.

[0031] Step 2: Set the parameter range of the pulse current, and determine the pulse current parameters of the sample as 100Hz, 200μs, 200A.

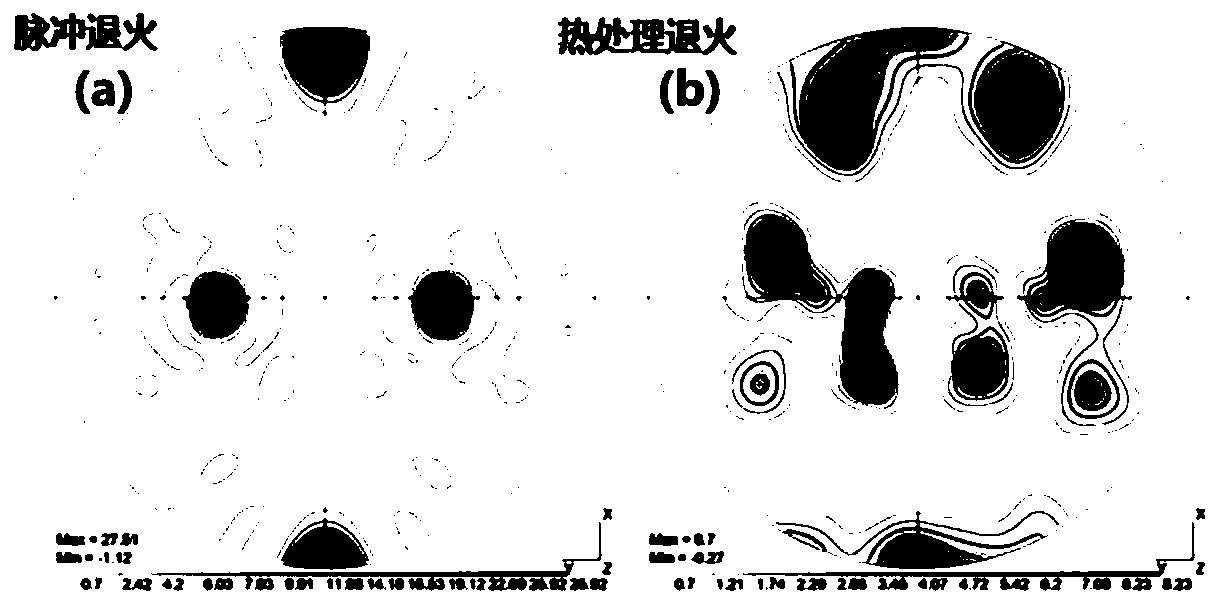

[0032] Step 3: Apply the MgO coating evenly on the cold-rolled sample A and fix it on the output end of the pulse power supply with a clamp, so that the current direction is parallel to the rolling direction, and perform pulse current annealing treatment for 5 minutes. At the same time, the cold-rolled sample B is uniformly After the MgO coating was applied, it was fixed at the output end of the pulse power supply with a clamp so that the current direction was perpendicular to the rolling direction, and pulse current annealing was performed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com