Immobilized enzyme of core-shell structure as well as preparation method and application of immobilized enzyme

A technology of immobilized enzymes and core structures, applied in biochemical equipment and methods, immobilized on/in organic carriers, oxidoreductases, etc., can solve the problem of low recovery rate of immobilized enzyme activity and difficult control of network size , low activity of immobilized enzymes, etc., to achieve good microenvironment, high enzyme activity retention rate, and improve immobilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Accurately weigh a certain amount of organophosphate hydrolase (OPH), and prepare an enzyme solution with a concentration of 1 mg / mL with a 50 mM, pH=9.0 phosphate buffer solution;

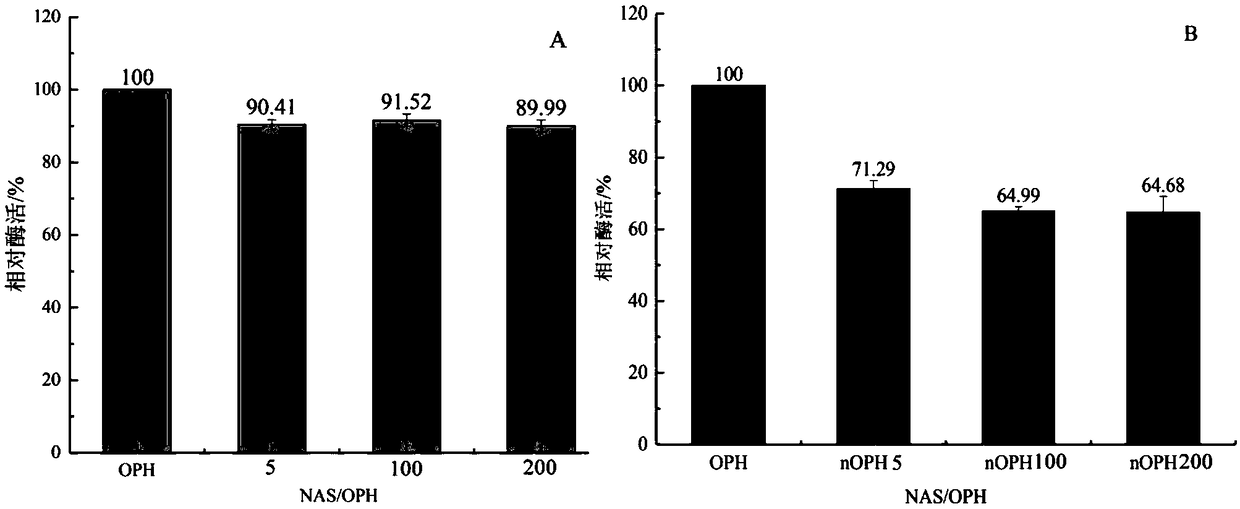

[0038] (2) Double-bond modification of the protein: For the enzyme solution prepared in step (1), pipette 20mL of the enzyme solution into three 25mL glass vials, and follow the N-acryloyloxysuccinimide (NAS) : Enzyme = [5:1; 100:1; 200:1] (molar ratio) for feeding, put the solution in a water bath at 30°C for 1 hour, and obtain double bond modified enzyme solutions OPH-NAS5, OPH-NAS100, OPH -NAS200;

[0039] (3) Subsequently, pipette 10 mL of the double bond-modified enzyme solutions OPH-NAS5, OPH-NAS100, OPH-NAS200 in step (2) respectively, put them into three 25 mL glass vials, add monomer acrylamide (AAM ), nitrogen gas was slowly passed into the solution for 3min; then, the cross-linking agent N,N-methylenebisacrylamide (BIS), the initiator ammonium persulfate (APS) and the cataly...

Embodiment 2

[0044] (1) Accurately weigh a certain amount of organophosphate hydrolase, and prepare an enzyme solution with a concentration of 10 mg / mL with a 50 mM, pH=8.0 phosphate buffer solution;

[0045] (2) Double bond modification of protein: feed the enzyme solution prepared in step (1) according to NAS: enzyme = 10:1 (molar ratio), put the solution in a refrigerator at 4°C for 10 hours to obtain double bond modification Enzyme solution OPH-NAS10;

[0046] (3) Subsequently, pipette 10 mL of the enzyme solution OPH-NAS10 modified by the double bond in step (2), place it in four 25 mL glass vials, add N-(3-aminopropyl)-methacrylamide Hydrochloride (APM), nitrogen gas was slowly passed into the solution for 3 minutes, and then the following mass ratios of the cross-linking agent BIS (OPH: BIS = 1: 0.1 / 0.2 / 0.5 / 1) were added to the 4 vials respectively;

[0047] (4) then, in the enzyme solution of step (3), add initiator ammonium persulfate (APS) and catalyzer tetramethylethylenediamin...

Embodiment 3

[0050] (1) Accurately weigh a certain amount of organophosphate hydrolase, and prepare an enzyme solution with a concentration of 5 mg / mL with a phosphate buffer solution of 50 mM and pH=7.5;

[0051] (2) Double-bond modification of the protein: feed the enzyme solution prepared in step (1) according to sodium acrylate (AAS): enzyme = 200:1 (molar ratio), and place the solution at room temperature at 25°C for 5 hours. Obtain double bond modified enzyme solution OPH-NAS50;

[0052] (3) Subsequently, pipette 10 mL of the enzyme solution OPH-AAS200 modified by the double bond in step (2), place it in three 25 mL glass vials, and add mixed monomer 1 (mass ratio AAM:APM=1: 3), mixed monomer 2 (mass ratio AAM:APM=2:2), mixed monomer 3 (mass ratio AAM:APM=3:1), slowly feed nitrogen into the solution for 3min; then, add nitrogen to the enzyme solution Add the cross-linking agent N, N-methylenebisacrylamide (BIS), the initiator ammonium persulfate (APS) and the catalyst tetramethyleth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com