Blue red phosphorus flame retardance reinforced polyamide material

A polyamide and red phosphorus technology, applied in the field of blue red phosphorus flame retardant reinforced polyamide materials, can solve the problem of difficult to obtain high-definition laser marking, unclear effect of red phosphorus flame retardant nylon, dark yellow or dark gray, etc. problem, to achieve the effect of good color stability, clear effect, good mechanical properties and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

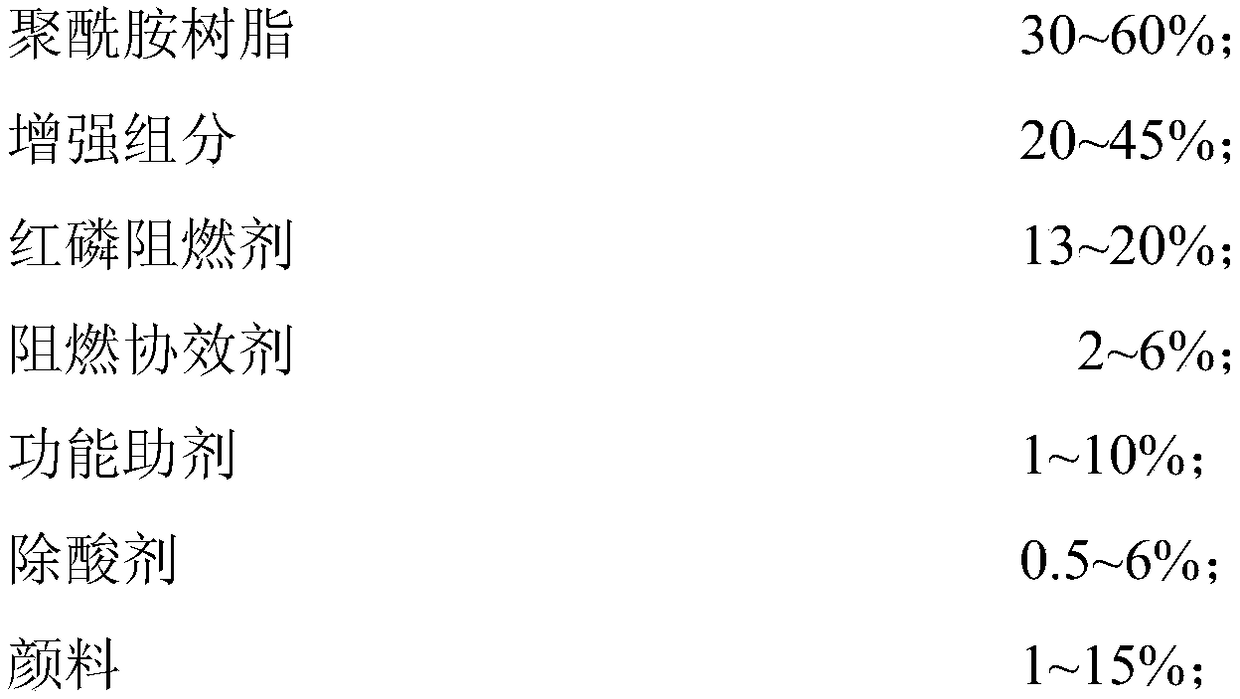

Method used

Image

Examples

Embodiment Construction

[0059] The raw material formulations of each of the following examples 1 to 5 and comparative examples 1 to 2 are respectively listed in the following table 1, and all adopt the following preparation process:

[0060] Step (1): PA66, PA6, and microcapsule red phosphorus masterbatch are pre-dried. PA66 and PA6 are dried at a drying temperature of 100-120°C for 10-12 hours; microcapsule red phosphorus masterbatch is dried at 90°C Under high temperature, the drying time is 3-5 hours.

[0061] Step (2): Mix other components except the alkali-free glass fiber with PA66 and PA6 pre-dried in step (1), and microcapsule red phosphorus masterbatch in parts by weight to obtain a mixture.

[0062] Step (3): Put the above-mentioned mixture and alkali-free glass fiber into the main feeding hopper and side feeding hopper of the twin-screw extruder respectively, melt and extrude at a processing temperature of 210-275°C, and cool and form , pelletized to prepare blue red phosphorus flame reta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com