Moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer and preparation method thereof

A technology of composite particles, silicon-magnesium-boron-zinc, applied in the field of agriculture, can solve the problems affecting the application performance of other fertilizers, increase the difficulty of mechanized fertilization, and increase the difficulty of storage, so as to be suitable for large-scale production, improve the performance of mechanical application, reduce the The effect of storage difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

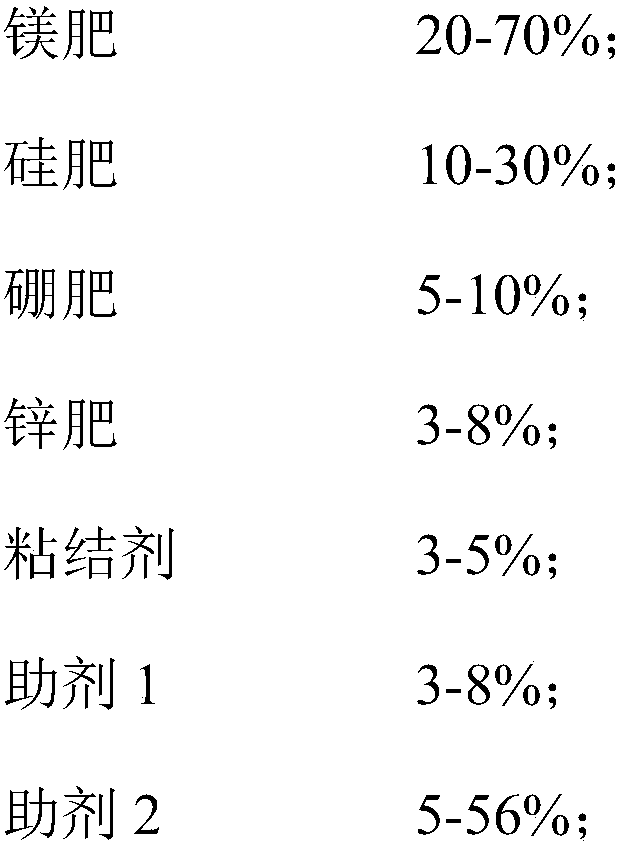

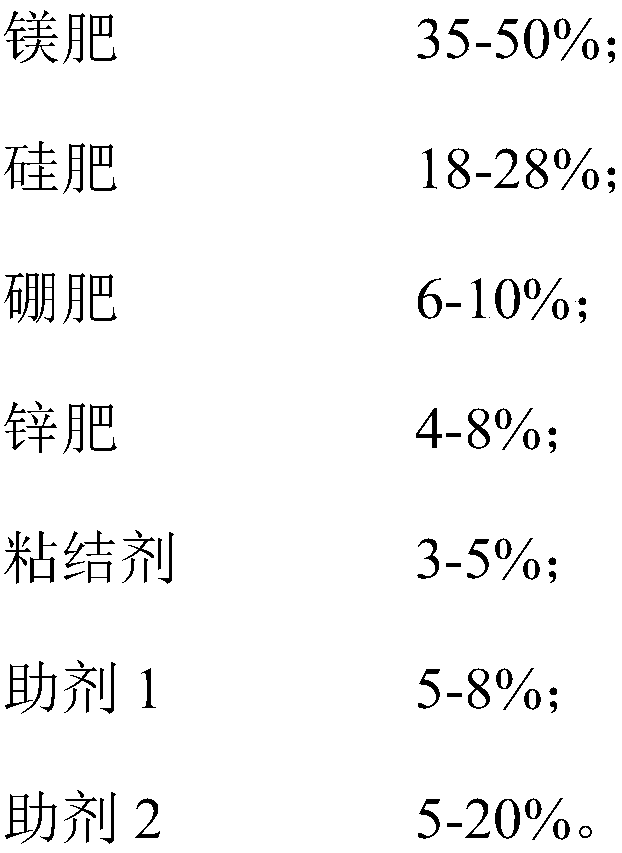

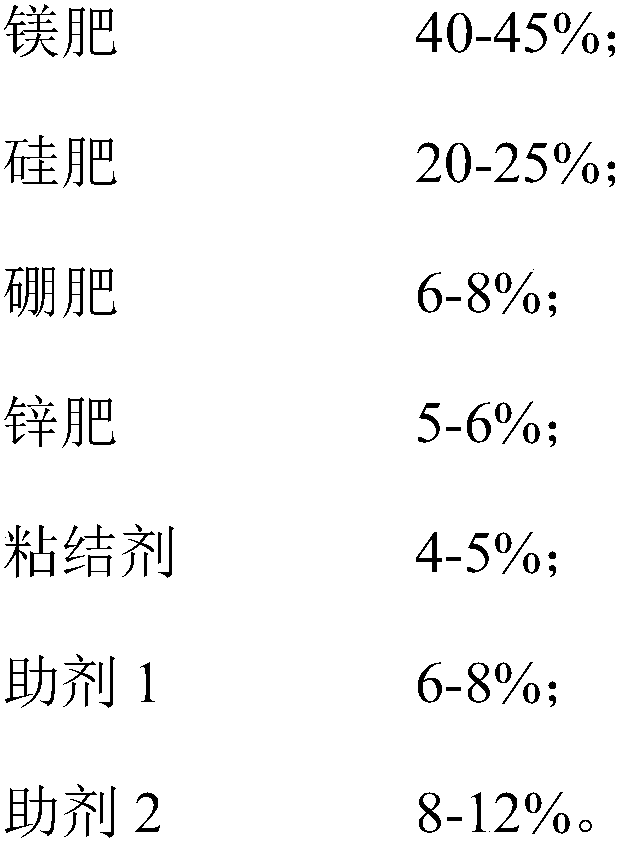

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer, the preparation method of which comprises the following steps:

[0042] (1) Mix 42kg of magnesium sulfate heptahydrate, 3kg of quicklime and 0.5kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture A.

[0043] (2) Mix 22kg of sodium metasilicate pentahydrate, 2kg of quicklime and 0.4kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture B.

[0044] (3) Mix 8 kg of borax, 0.9 kg of quicklime and 0.2 kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture C.

[0045] (4) Mix 5kg of zinc sulfate heptahydrate, 0.8kg of quicklime and 0.2kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture D.

[0046] (5) Mix 4 kg of ...

Embodiment 2

[0053] This embodiment provides a moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer, the preparation method of which comprises the following steps:

[0054] (1) Mix 35kg of magnesium sulfate heptahydrate, 2kg of quicklime and 0.5kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture A.

[0055] (2) Mix 18kg of sodium metasilicate pentahydrate, 0.8kg of quicklime and 0.2kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture B.

[0056] (3) Mix 10kg of borax, 0.6kg of quicklime and 0.2kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture C.

[0057] (4) Mix 8 kg of zinc sulfate heptahydrate, 0.5 kg of quicklime and 0.2 kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture D.

[0058] (5) Mix 7 kg ...

Embodiment 3

[0065] This embodiment provides a moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer, the preparation method of which comprises the following steps:

[0066] (1) Mix 57kg of magnesium sulfate heptahydrate, 2.5kg of quicklime and 0.5kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture A.

[0067] (2) Mix 15kg of sodium metasilicate pentahydrate, 0.8kg of quicklime and 0.1kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture B.

[0068] (3) Mix 5 kg of borax, 0.5 kg of quicklime and 0.1 kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture C.

[0069] (4) Mix 3kg of zinc sulfate heptahydrate, 0.4kg of quicklime and 0.1kg of calcium magnesium phosphate fertilizer evenly, pulverize them, and pass through a 20-mesh sieve to obtain mixture D.

[0070] (5) Mix 3 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com