Method for rapid aerobic composting

An aerobic composting and rapid technology, which is applied in the field of solid waste recycling, can solve problems such as long time consumption, and achieve the effects of reducing farmland environmental pollution, speeding up composting reaction speed, and saving composting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the specific steps for rapid aerobic composting of residual sludge and corn stalks (with a particle size of 1 to 5 mm) after sewage treatment in a food factory are as follows:

[0038] (1) Mixing: Mix the excess sludge and corn stalks from food factory sewage treatment in a ratio of 6:4. / N) ratio is 25, moisture content is 60%, puts into the composting reactor after mixing, and keeps stirring.

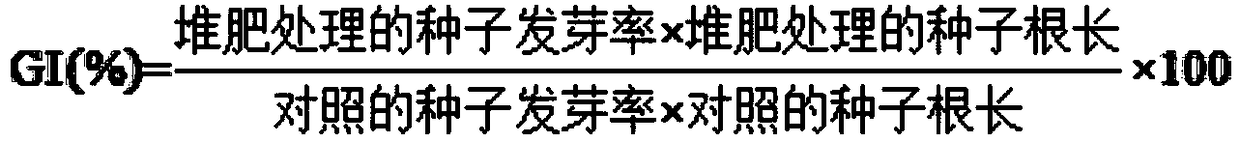

[0039] (2) Staged aerobic composting: the composting temperature is controlled at 35°C, and the ventilation rate is 5.5m 3 / h, composting for 12h; then, the composting temperature is controlled at 55°C, and the ventilation rate is 10m 3 / h, composting for 58h; finally, the composting temperature is controlled at 65°C, and the ventilation rate is 5.5m 3 / h, composting 2h. At the end, the material seed germination index was 74.58%, basically decomposed.

[0040] (3) Post-decomposition: take out the material after the staged aerobic composting, adjust the mo...

Embodiment 2

[0042] In this embodiment, the specific steps for rapid aerobic composting of excess sludge and corn stalks (with a particle size of 1 to 5 mm) by using sewage from a food factory are as follows:

[0043] (1) Mixing: Mix the remaining sludge and corn stalks from the sewage treatment of food factories in a ratio of 9:1. The moisture content of the remaining sludge and corn stalks is 80% and 12% respectively, so that the carbon and nitrogen of the compost raw materials ( C / N) ratio is 15, moisture content is 55%, puts into composting reactor after mixing, and keeps stirring.

[0044] (2) Staged aerobic composting: the composting temperature is controlled at 30°C, and the ventilation rate is 3.5m 3 / h, compost for 24h; then, control the compost temperature at 60°C, and the ventilation rate is 12m 3 / h, composting for 47h; finally, the composting temperature is controlled at 75°C, and the ventilation volume is 3.5m 3 / h, composting 1h. At the end, the material seed germination ...

Embodiment 3

[0047] In this embodiment, the specific steps for rapid aerobic composting of excess sludge and corn stalks (with a particle size of 1 to 5 mm) by using sewage from a food factory are as follows:

[0048] (1) Mixing: Mix the excess sludge and corn stalks from food factory sewage treatment in a ratio of 5:5. / N) ratio is 30, moisture content is 65%, puts into the composting reactor after mixing, and keeps stirring.

[0049] (2) Stage-by-stage aerobic composting: the composting temperature is controlled at 40°C, and the ventilation rate is 7.5m 3 / h, composting for 10h; then, control the composting temperature at 50°C and the ventilation volume at 7m 3 / h, composting for 59h; finally, the composting temperature is controlled at 60°C, and the ventilation rate is 3.5m 3 / h, composting 3h. At the end, the material seed germination index was 68.72%, basically decomposed.

[0050] (3) Post-decomposition: take out the material after the staged aerobic composting, adjust the moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com